Shanghai Beyond Machinery Co., Ltd |

|

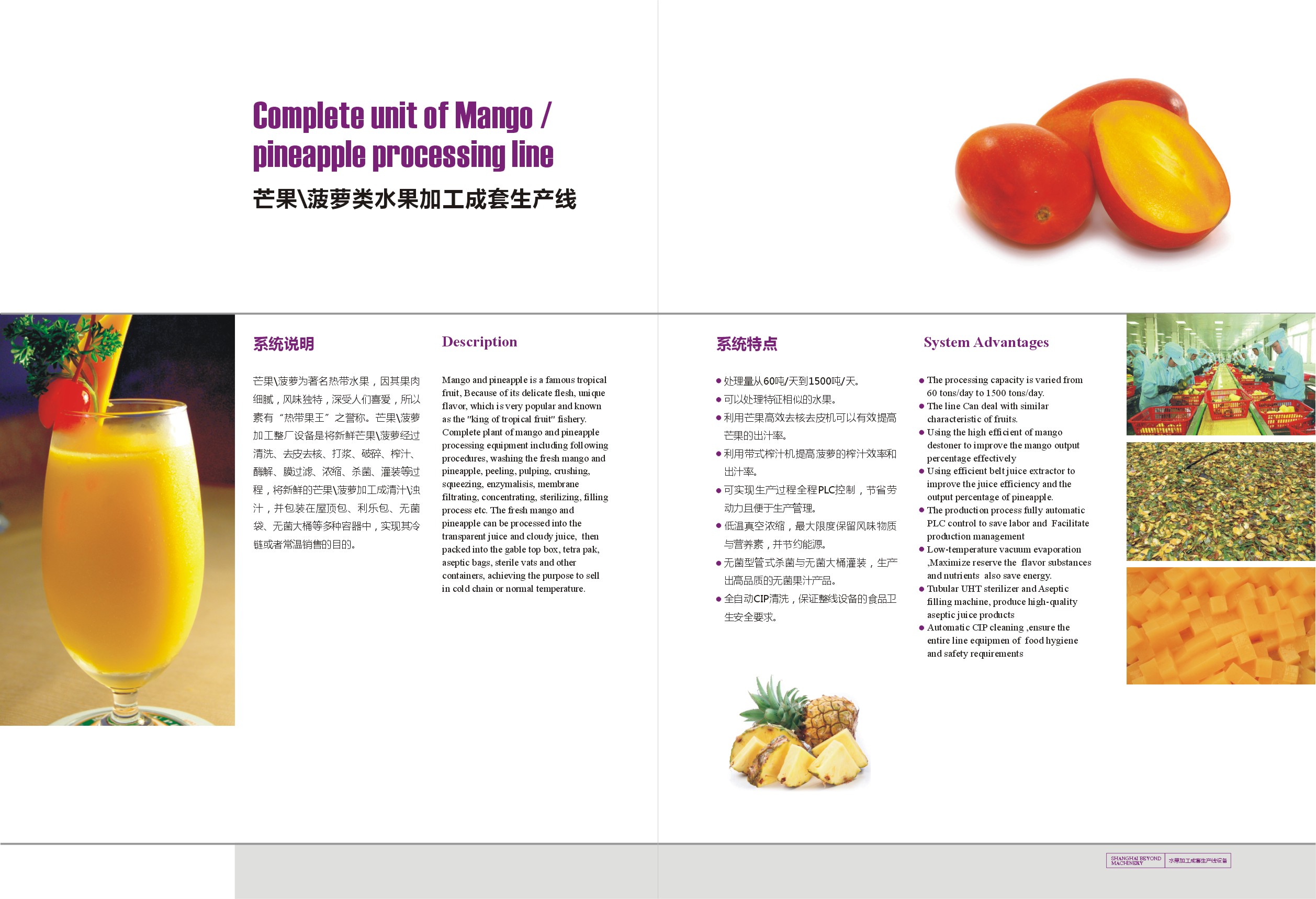

Pineapple processing line pineapple production equipment pineapple juice processing machine

Complete pineapple processing equipment includes the following steps: fresh pineapple cleaning, peeling, extraction, enzyme treatment, filtration, concentration, sterilization, filling, etc. Fresh mango can be processed into transparent juice and cloudy juice, and then put into sterile bags or PET bottles. Some Asian and South American countries are major exporters of pineapple products, mainly canned pineapple, pineapple concentrate and fresh pineapple.

Siva Engineers has established a pineapple concentrate and canned pineapple production line. These two production lines are usually combined, because the best pineapple is used for canning and fresh distribution, and fruit juice is a by-product of this process. Lower quality fresh pineapple is used for juice and pineapple concentrate production.

Specifications:

| Brand Name: | Shanghai Beyond |

| Model Number: | BY-MPL05 |

| Capacity | 5-50T/H |

| Raw material | Fresh pineapple |

| End product | NFC fresh juice, concentrated juice, Concentrated juice, clear juice, ,cloudy juice |

| Juice yield | 50-75% |

| Fruit input brix | 10-20brix (fresh fruit) |

| End product brix | 60~72Brix( for concentrated ) |

| Package for end product | Aseptic large bag in drum/ glass bottle/PET bottle, Gable top box/ brick shape carton |

| Certification: | ISO9001/CE/SGS |

| Main material for machines | SUS304 or SUS316 |

| Place of Origin: | China |

| Manufacturer history | More than 10years |

| Voltage | 380V 50Hz/110V 60hz/415V 50Hz |

| Power consumption(Kw) | energy saving type, about 100-500kw, |

| Operator needed | About 6-20persons |

| Cooling water consumption | About 80-300M3 |

| Steam consumption | About 300-5000T/H, |

| Factory space needed | About 500-5000Sqm |

| Warranty | 12 months after commissioning |

After sales service | Engineers available to service machinery overseas |

Complete pineapple juice production line:

1 The processing capacity varies from 1 ton/hour to 10 tons/hour.

2 This line can handle similar characteristics of fruits.

3. High efficiency belt juicer is adopted to improve the juice efficiency and output of pineapple.

4. Low temperature vacuum evaporation 8 greatly reduces the loss of flavor substances and nutrients.

5. Tubular UHT sterilizer and sterile filling machine are isolated from bacterial contamination to ensure food safety and extend product shelf life.

6. A complete set of production from CIP system reduces labor intensity and ensures high level of sanitation.

Complete pineapple juice production line:

1. Pineapple washing machine

2. Sort conveyor

3. Juicer

4. Belt conveyor and vibrating screen

5. Pineapple juice mixing tank/enzyme treatment

6. Preheater

7. Decanter or centrifuge

8. Fruit juice evaporator

9. Juice sterilization aseptic filling machine/juice bottle filling

10. Pineapple corer and caliper

11. Pineapple slicer/pineapple peeler/pineapple chips

12. Tank reforming unit

13. Automatic fruit juice sterilizer

| Equipment list for 2T/H fresh mango pulp & pineapple juice procession line | |||||

| 1 | A | Fruit washing unit | |||

| 2 | A-1 | Surfing bubble washing machine | 2T/H | SUS304, fruit washing tank (2M*1M*1.2M), water blowing pump,blow fan, clapboard elevator(5M*0.8M*4M) with spraying device, elevator speed is adjustable by frequency convertor | 1 |

| 3 | A-2 | Belt sorting machine | 2T/H | Main material for equipment is SUS304 stainless steel, material for frame supporter is SUS304 stainless steel rectangular steel, size for roller sorting machine is 4000mm*1200mm (length*width), motor power is 1.5kw, including fruit sorting operation platform (SUS304 stainless steel), size is 4000mm*600mm | 1 |

| 4 | A-3 | Stainless steel clapboard elevator | 2T/H | Material for clapboard is SUS304 stainless steel, material for frame supporter is SUS304 stainless steel rectangular steel, size for elevator is 5000mm*600mm (length*width), power is 2.2kw, frequency conversion control | 1 |

| 6 | B | Crushing and pulping unit | |||

| 7 | B-1 | Pineapple crusher | 2T/H | made of SUS304 stainless steel, side plate 2mm thick;external size 1200×1000×1400mm, power 7.5kw | 1 |

| 8 | B-2 | Mango Destoner | 2T/H | SUS304 frame,speed is adjustable by transducer,rubber mover plate,with brush | 1 |

| 9 | B-3-1~2 | screw conveyor | Main material for equipment is SUS304 stainless steel, material for frame supporter is SUS304 stainless steel rectangular steel, external size is 4000mm×φ250mm | 2 | |

| 10 | B-4-1~2 | Buffer storage tank | V=500L | SUS304,single layer, big opening, bottom with square flange outlet, adjustable legs | 2 |

| 11 | B-5-1~2 | Screw pump | 2T/H | Sanitary grade,outlet pressure≤0.6MPa | 2 |

| 12 | B-6 | Tubular pre-heater | 2T/H | SUS304, tubular type, steam heating directly, outlet temperature 85-90℃,temperature is manually controlled | 1 |

| 13 | B-7 | Double stage pulping machine | 2T/H | SUS304, double stage pulping, first stage rotary speed 960rpm,screen hole diameter 1.0mm, second stage 1200rpm, screen hole diameter 0.6mm | 1 |

| 14 | B-8 | Spiral squeezer | 2T/H | The main part of the equipment adopts SUS304, and the speed of the waste coming is adjustable, frequency control | 1 |

| 15 | B-9 | Crushing and pulping platform | carbon steel frame, outside coating with anti-corrosion paint,stainless steel checker plate, staircase with handrail, water drain in central | 1 | |

| 17 | C | Concentrating and storage unit | |||

| 18 | C-1 | Temporary storage tank | 4000L | SUS304, double layer, on top with off-central vertical agitator, CIP spraying ball, adjustable legs, ladder, digital show thermometer, breath cap | 2 |

| 19 | C-2 | Screw pump | 2T/H | Sanitary grade,outlet pressure≤0.6MPa | 1 |

| 20 | C-3-1~2 | Centrifugal pump | 10T/H | SUS304 stainless steel, 24 meters lift, mechanical seal, ABB motor | 1 |

| 21 | C-4 | Single effect forced circulation evaporator | Q=1T/H | SUS304, fully automatic PLC control, evaporation capacity 1T/H | 1 |

| 22 | C-5 | Buffer tank | V=2000L | SUS304, single layer, on top with off-central vertical agitator, CIP spraying ball, adjustable legs, ladder, digital show thermometer, breath cap | 1 |

| 23 | C-6 | Screw pump | Q=2T/H | food grade, outlet pressure ≤0.6MPA | 1 |

| 25 | D | Sterilizing filling unit | |||

| 26 | D-1 | Tube-in-tube sterilizer | 0.5T/H | adopt the full automatic Simens PLC control,sterilizing temperature 105℃, 60s, material outlet temperature 30 ℃, UK Spirax Sarco steam control system, with CIP cleaning unit | 1 |

| 27 | D-2 | Degasser unit | 0.5T/H | Automatic control, SUS304, with the degassing tank, vacuum pump, and material pump, Labom Differential pressure sensor control level | 1 |

| 28 | D-3 | Homogenizer | 0.5T/H | SUS304, maximum pressure 25Mpa, with start cabinet, frequency converted control | 1 |

| 29 | D-4 | Aseptic large bag filling machine | 0.5T/H | Aseptic large bag filler, 220kg, single heads , automatic control, self-leaning system, with Motorless drum rolling conveyor | 1 |

| 31 | E | Blending unit | |||

| 32 | E-1 | Emulsification tank | 1500L | SUS304 stainless steel, 60mm PU insulation, high speed stirring 1400rpm at bottom, digital display thermometer, built-in scale, conical cover, CIP cleaning ball, high and low level sensor, special sugar funnel | 1 |

| 33 | E-2 | Centrifugal pump | 10T/H | SUS304 stainless steel, 24 meters lift, mechanical seal, ABB motor | 1 |

| 34 | E-3 | Twin tube filter | 10T/H | SUS304 stainless steel, 200 mesh, stainless steel filter net, twin tube | 1 |

| 35 | E-4 | Dissolving platform | SUS304 stainless steel, stainless steel pattern plate, handrail and ladder, centralized drainage, size is about 1200*1200*1200mm | 1 | |

| 36 | E-5-1~3 | Blending tank | 6000L | SUS304 stainless steel, single layer,off-center agitator, 36 rpm, airtight manhole, digital display thermometer, CIP cleaning ball, adjustable legs, acid spraying nozzel, sample valve | 3 |

| 37 | E-6 | Centrifugal pump | 10T/H | SUS304 stainless steel, pump head is 36 lift, mechanical seal, ABB motor | 1 |

| 38 | E-7 | Inverted screw pump | 5T/H | Inverted screw pump, with dynamic cart, can be lifted, speed stepless adjustable, the part touched with product is SU304L stainless steel | 1 |

| 39 | E-8 | Twin barrel filter | 10T/H | SUS304 stainless steel, 40 mesh, stainless steel filter net, twin tubes | 1 |

| 40 | E-9 | Blending platform | SUS304, stainless steel pattern plate, handrail, ladder, centralized drainage,size 4500*800*1800mm | 1 | |

| 42 | F | Sterilizing and filling unit | |||

| 43 | F-1 | Tubular sterilizer | Q=6T/h | Material: SUS 304 tubular type, Sterilization temperature range: 25~50℃→95℃(30S)(sterilization)→88℃(hot filling) Spirax sarco steam pressure relief and regulating valve system, steam trap, Germany Jumo temperature sensor. Germany Burkert tower water regulator, GEA/APV pneumatic valve, paperless temperature recorder,Siemens PLC touch screen control, with self CIP cleaning system | 1 |

| 44 | F-2 | Vacuum degasser | Q=6T/h | SUS304, differential pressure transducer, water circulation type vacuum pump, working vacuum degree-0.08MPa, vertical multi-stage centrifugal pump, frequency converted control | 1 |

| 45 | F-3 | Homogenizer | Q=6T/h | SUS304, maximum pressure 25Mpa, with start cabinet, frequency converted control | 1 |

| 46 | F-4 | PET bottle filling machine | Q=6T/h | 500ml/b, 12000B/h, tilt bottle sterilizing, spray cooling tunnel, conveyor chain, with ink jet date coder, dryer, labeling machine, shrink labeling machine, shrink film wrapping machine, carton packing machine, etc | 1 |

| 48 | G | Hot water unit | |||

| 49 | G-1 | Hot water tank | V=3000L | SUS304, 60mm PU heat preservation, top and bottom 15° conical head, airtight manhole, respiration valve, the digital display thermometer, overflow tube, anti-vortex plate, pure water inlet, hot water reflux nozzel, glass tube indicator, ball float type sensor of high,middle, low level, bottom discharge valve with pull rod, adjustable legs, ladder | 1 |

| 50 | G-2 | Centrifugal pump | Q=5T/h | SUS304, lift 36 meters, mechanical seal | 1 |

| 51 | G-3 | Palte heater | Q=5T/h | SUS304, steam heating directly, plate Proof Pressure 8kg,60-95℃ | 1 |

| 52 | G-4 | Temperature control system | K Spirax sarco reducing valve, trap system, Chinese famous brand stop valve, steam instrument | 1 | |

| 54 | H | CIP unit | |||

| 55 | H | CIP system | 3*3000L | Three tanks, single circulation, Semi-auto CIP, double layers insulation tank, tank material SUS304 stainless steel,acid&alkali tank with stirrer, high&Low liquid level alarm system, Spirax Sarco temperature auto control, JUMO temperature sensor, Shanghai YUAN brand progress pump 1 pieces, 20T/H, pumping lift 36M,300L concentrated acid & alkali tank which material is SUS316L , The USA imported pneumatic diaphragm pump two pieces. | 1 |

| 56 | R | CIP return pump | 20T/H | SUS316L, 24m lift, mechanical seal, ABB motor | 2 |

| 59 | I | Installation part | |||

| 60 | I-1 | product piping system | CIP pipeline,processing pipeline and sewage pipeline of all the equipment from Beyond, and also all the needed valves, meters, ISO standard (Φ63,Φ51, Φ38 etc), SMS round thread standard | 1 | |

| 61 | I-2 | power piping system | including equipment steam pipeline(carbon steel pipe), ice water

pipeline(Hot dip galvanized pipe), tap water(Hot dip galvanized ) and compressed air pipeline(carbon steel pipe), and also needed valves,meters, not including the insulation of the pipes, buyer connect main pipe to required position | 1 | |

| 62 | I-3 | electrical distribution cabinets | including all the Beyond Provided equipments' power control cabinets and site control cabinets in the main workshop, made of stainless steel SUS304 | 1 | |

| 63 | I-4 | electric distributing system | All the needed cable and related electric parts for installation(cable, support, flexiable tube etc) of Beyond equipment | 1 | |

| 64 | I-5 | installation and commissioning cost | installation and commissioning on the equipments from seller's(Beyond) company,customer offer installation tools(welding machine, cutting machine, flat machine etc) and installation consumable materials(stainless steel welding sticks, carbon welding sticks, electric power, argon etc) | 1 | |

Pineapple processing

Pineapple is one of the most popular tropical fruits, and its consumption of delicious juice is increasing significantly. We have developed highly specialized technology for producing natural and concentrated pineapple juice. We are particularly proud of our special pineapple juice extractor, which ensures the highest product quality by minimizing any contact between the peel and the juice.

Cleaning, sorting and sizing

Our universal washing machine is suitable for cleaning any fruit destined for industrial transformation. The unit will go through two subsequent washing processes: soaking in the basin and taking a shower in the elevator.

After cleaning, pineapples are sent to our general sorting station, where staff can effectively check them.

According to the characteristics of plants and the fruit to be processed, pineapple can be sized instead of automatic sizing machine, and sent to different extraction machines according to the size

Fresh pineapples are placed in a concrete basin filled with water.

Juice extraction

Our special pineapple juicer cuts the fruit in half, extracts the juice and pulp, removes the peel, and obtains high-quality pulp juice at the same time. There is no contact between fruit juice and peel.

Juice refining

The spiral juicer is used for squeezing juice. Decanter or centrifuge can be used to further reduce the pulp content.

concentration

Our plate evaporator is very suitable for processing pineapple juice because of its short residence time and low temperature to maintain the sensory characteristics of the juice.

Sterilization and filling

The concentrated or natural pineapple juice with single concentration can be sterilized or pasteurized by plate sterilizer or plate sterilizer according to the specific requirements of the application.

Once sterilized, products can be put in sterile bags, barrels or boxes, thanks to the sterile filling machine.

Plant cleaning

All production lines are designed according to international food grade requirements and can be completely cleaned by adopting integrated cleaning procedures and systems or centralized and fully automatic CIP systems. We are specially designed to ensure perfect and efficient CIP for fruit processing plants.