Suzhou Energy Tool Co., Ltd. |

|

Verified Suppliers

|

|

9-1/2" PDC Hole Opener with PDC Cutter

1 . Descriptions:

What does PDC mean in drilling? Polycrystalline diamond materials,

for use in polycrystalline diamond compact (PDC) bits, are one of

the most important material advances for oil drilling tools in

recent years. Fixed-head bits rotate as one piece and contain no

separately moving parts.

Cutter density

Cutter size or type

Bit profile

Cutter Blades

All of our Drill bits are fit for API standard and used in the

drilling Industry. The PDC drill bits size 3~22inch with 3~9Blades

are available. And different classification cutter are optional

according to your budget .

2. Specification:

Polycrystalline diamond compacts PDC bit in the Oil and Gas Industry PDC bits get their name from the polycrystalline diamond compacts used for their cutting structure. A PDC bit is a drill bit fitted with industrial diamond cutters instead of hardened metal teeth.

SPECIFICATION

Size : 8 1/2inch (241.3mm)

Drill Body Type : Steel Body

Blades Quantity : 5

Nozzles Quantity : 5

API Connection (in) : 4-1/2" REG

Gauge Length (In): 6

OPERATIONAL PARAMETERS

Weight on Bit (KN): 5 -30

RPM Range(Rotary): 80- DHM

Flow Rate(lps): 400- 500 LPM

Make-Up Torque(KN): 17 -26.4KN.M

3 . Bit profile

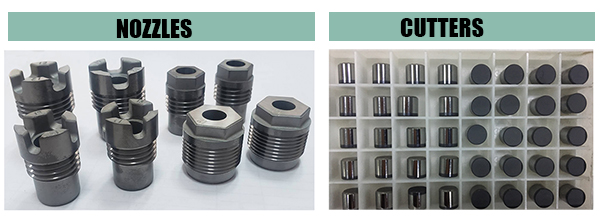

4 . Drill Bit PDC Cutters

Polycrystalline Diamond Composite (PDC) cutters are the main point

of contact for a drill bit. PDC bits remove the rock mainly by

shearing.

The PDC cutters are exposed to a lot of heating and cooling down

the well, a very challenging environment.

PDC cutters that have lower thermal degradation and more thermal

stability generally achieve higher ROP and increased wear

resistance. So, optimizing the cutter is important.

5. Drill Bit Nozzles

Drill bit nozzles help clear the cutting area and cool the

Polycrystalline Diamond Composite (PDC) cutters.

Effective placement of these nozzles along with the angle they are

set at plays a critical role on how efficient the drill bit

performs.

Fluid channels also complement nozzle placement to imp