|

|

[China]

Trade Verify

Address: Luocun New Light Source Industrial Base, Shishan Town, Nanhai District, Foshan City, Guangdong Prov., China 528200.

Contact name:Sylar

Foshan Xiong Qi Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

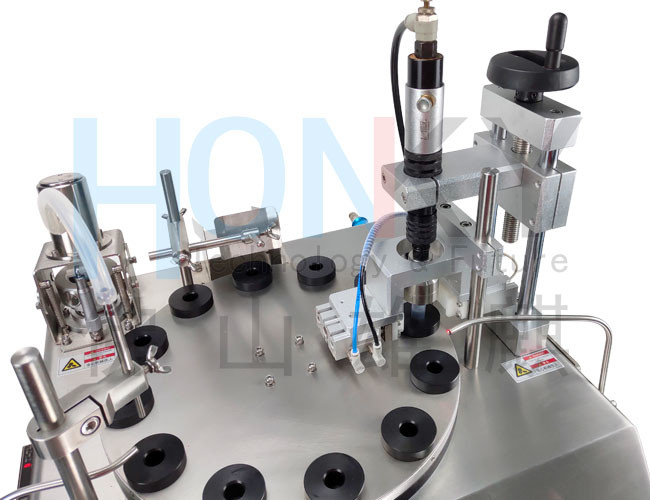

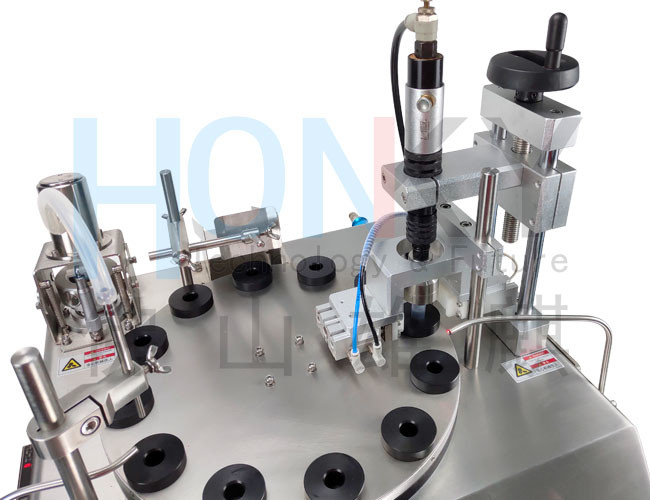

Semi Automatic 2000 BPH Vial Capping Machine With Ceramic Pump

2000BPH Cryo Tube Semi-Automatic Vial Filling And Capping Machine With Ceramic Pump For Reagent

Characteristic

XQZGX-12S adopts a rotary tabletop design, which is specially designed for cryopreservation tube and reagent bottle packaging. The filling part uses high-precision ceramic piston metering pumps to ensure filling accuracy, fast filling speed, and wide range. The capping part adopts air cylinder to twist the cap. The whole machine is made of sanitary stainless steel, which is good and sanitary.

Technical data

| Model | XQZGX-12A |

| Pump type | Ceramic pump |

| Filling accuracy | ≦±0.5% |

| Filling range | 0.6-6ml |

| Manufacturing speed | 25-30 PCS / minute |

| Power | AC 220V 50-60Hz 550W |

| Air pressure | 0.4-0.6Mpa |

| Machine size | 710*660*670mm (Main machine roughly) |

Semi Automatic Capping Machine Display

2000BPH Cryo Tube Semi-Automatic Desktop Filling And Capping Machine With Ceramic Pump For Reagent

This equipment has been tested to meet the requirements of GMP certification.

Bottle type

The capping part adopts AIR torsional screwing to ensure the tightness of the lid.

The separation part adopts high purity ceramic pump, which controls the injection volume of each lap by adjusting the angle of the pump head, and has extremely high measuring accuracy and repeated consistency.

Fully desktop design to make operation easy.

Advantages for using the ceramic pump:

1. Low Friction, Increased Packing Life

2. Extreme Wear Resistance

3. Increased Corrosion Resistance

4. Improved Anti-Galling Surface

Application area

1. ODM and OEM products design;

2. Automatic manufacturing line design;

3. Cosmetic product packing;

4. Pharmaceutical and bio-reagent product packing;

5. Laboratory Liquid dispensing;

6. Lithium Battery Liquid dispensing;

7. Ceramic pump and ceramic pump part design;

8. Other area's material filling;

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support.

Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime

after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine

purchases. We will provide the user manual and videos to support

installing, debugging, operation of the machine, which will

indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.