Shenzhen SMTfly Electronic Equipment Manufactory Limited |

|

Verified Suppliers

|

|

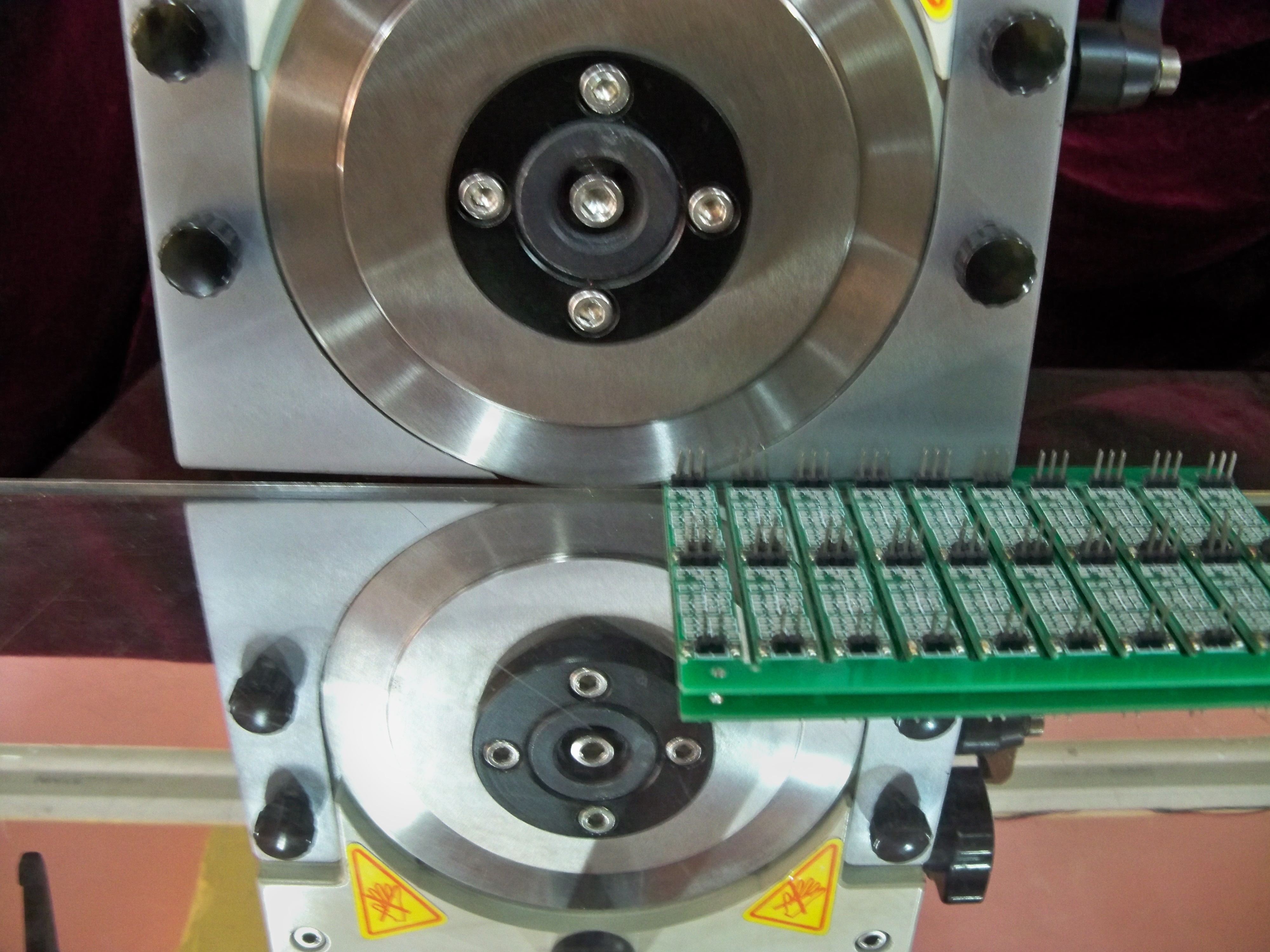

330mm Pcb Cutter Depanel Cutting Pre-scored Printed Circle Boards

SMTfly-1 separates small amounts and prototype series of PCBs fast and economically. The circular blades and guides made out of special steel ensure a long durability. The compact and stable aluminium frame requires only a minimum of space. The PCB is shoved manually between the circular blades and is thereby separated.

Features :

1. The machine is used to separate "v" groove base board , compared

to the traditional hand-breaking score board , not only greatly

improve production efficiency and product quality have a better

guarantee.

2. Simple operation, fast speed , ensuring base board electronic

components are not damaged by the movement.

3. Straight knife slip speed can manual control , V groove guide

device adjustable height , more quickly adapt to different

thickness of the base board .

4. Reduce the internal stress generated by the PCB Separator to

avoid cracking of tin .

5. Round knife can multiple times turn mill and reuse

Package: plywood case (free)

Specification :

| Pcb Separator machine Size | 420mm x 280mm x 400 mm |

| The Longest Minimize | 330mm |

| Minimize Speed | 0-40mm/s |

| cutting thickness | 1.0-3.5mm |

| Pcb Separator Machine Weight | 70Kg |

please note:

round knives will often be sufficient for separating uncomplicated panels or cutting off margin waste. However, for high-grade boards with components right up to the dividing line, better quality can be achieved if the separation is carried out simultaneously with linear knives along the whole length of the board

More information welcome to contact us:

Email: sales@dgwill.com

Wechat/Skype:+86 18166146357

24 Hours Service,Welcome to Inquiry!!