Shenzhen SMTfly Electronic Equipment Manufactory Limited |

|

Verified Suppliers

|

|

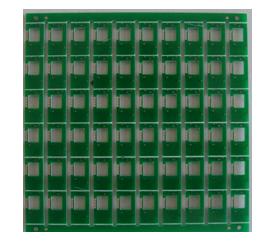

High Efficiency V-cut Pcb Separator , Automatic Pcb Cutting Machine

1. Separate pre-scored PCB assembly without stress on either PCB or component

2. One touch programming of cut length with digital display

3. Separating speed is adjusted by a rotary knob

4. Handle Intermittent scoring or cut-outs

5, Board with projected component can be cut precisely

6. Large stainless steel platform on both side of cutting blade prevents board wobble and table height and angle are adjustable

7. Optional PCB conveyor belt to remove finished board

8. Clearance between circular and linear blades are adjustable to fit different groove depth and compensates for blade wear out

Specifications:

Model: | SMTfly-1A600 |

Size: | 1080*860*660mm |

Machine Weight: | 120Kg |

Minimize thickness: | 0.6-3.5mm |

Minimize Speed: | 100/200/300/500mm/s |

The Longest Minimize: | 600mm |

Competitive Advantage:

Our Service:

A. Pre-consultation:provides professional SMT solution for the full line;

B. Factory Warranty:One-year warranty factory service;

C. Installation:On-site installation and commissioning,to ensure smooth production;

D. Technical Training:provides professional training from level 1 to level 3;

E. Technical Support:provides 7 days * 24 hours technical support;

F. Software Upgrade:offer lifetime free software upgrades for all products.

More information welcome to contact us:

Email: sales@dgwill.com

Wechat/Skype:+86 18166146357

24 Hours Service,Welcome to Inquiry!!