GUANGDONG RUIHUI INTELLIGENT TECHNOLOGY CO., LTD. |

|

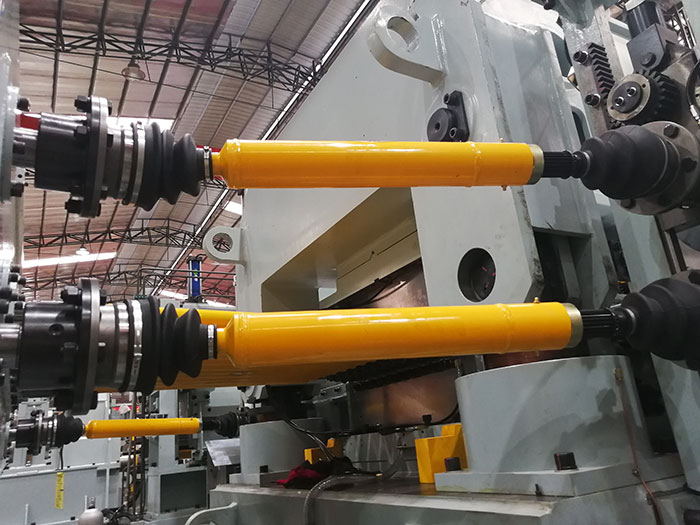

3-in-1 feeder feeding trolley loading method: After the coil is

placed, the hydraulic motor control system controls the hydraulic

motor to work, and the hydraulic motor drives the driving sprocket

to roll on the chain guide to promote the movement of the trolley.

After moving to the designated position, the oil control system

controls the lifting cylinder to push the frame of the trolley to

rise. When the frame is raised, the driving sprocket and the driven

sprocket connected to the right and left arms are close to each

other. The support frame rises.

When the inner ring of the coil is aligned with the tensioning

device of the 3-in-1 feeder rack portion, the hydraulic motor

drives the trolley frame to continue to advance the coil into the

tensioning device, and the tensioning device tightens the coil.

After fixing, the car reverses the action and completes the

feeding.

The weight of the material carried by the MAC feeder is large (usually above 3T), so special attention should be paid

to the loading and unloading. The loading trolley is one of the

optional devices for customers to purchase the 3-in-1 feeder. It is

set in 3-in-1. 1 The side of the feeder rack part can automatically

feed the coil into the tensioning device of the rack part, and the

feeding is accurate and fast.

When using the trolley device for loading and unloading the

three-in-one feeder, the following instructions must be followed to

avoid unnecessary dangers:

1. Please do not drop the material roll directly onto the rack and

roll it into the equipment.

2. All the coil positioning and auxiliary equipment are emptied for

loading and unloading, but the trolley device must be used for

loading and unloading at a safe/reasonable speed.

3. When feeding and feeding, confirm that the coil is fully

supported. It is worth mentioning that the coil should not be

overweight.

Specification:

| Model | MAC2-400 | MAC2-500 | MAC2-600 | MAC2-800 | ||

| Stock Width(mm) | 50-400 | 50-500 | 50-600 | 50-800 | ||

| Stock Thickness(mm) | 0.3~3.2 | 0.3-3.2 | 0.3-3.2 | -3.2 | ||

| Max.Coil Weight(kg) | 3000 | 3000 | 3000 | 5000 | 5000 | 7000 |

| Max.Coil O.D.(mm) | 1200 | 1200 | 1200 | |||

| Coil I.D.(mm) | 8 | 8 | 508 | 508 | ||

| Feed Length(mm) | ~500* | ~500* | ~500* | ~500* | ||

| Max. Line Speed(m/min) | 16-24 | 16-24 | 16-24 | 16-24 | ||

| Work Roll Number(pieces) | upper 6 lower 5 | upper 6 lower 5 | upper 6 lower 5 | upper 6 lower 5 | ||

| Feed Roll Number(set) | 1 | 1 | 1 | 1 | ||

| Main Motor(kw) | AC2.9 | AC2.9 | AC4.4 | AC4.4 | ||

| Mandrel Expansion | hydraulic | hydraulic | hydraulic | hydraulic | ||

| Reel Motor(kw) | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 |

| Power(V) | 3 Phase 220V/380V/50HZ | |||||

| Operating Air(Mpa) | 0.49 | 0.49 | 0.49 | 0.49 | ||

Straigtening performance:

| tock Thicknees (mm) | Stock Width (mm) | |||

| 0.3 | 400 | 500 | 600 | 800 |

| 0.4 | ||||

| 0.6 | ||||

| 0.8 | ||||

| 1.0 | ||||

| 1.2 | ||||

| 1.4 | ||||

| 1.6 | 470 | 470 | ||

| 1.8 | 400 | 400 | ||

| 2.0 | 360 | 360 | ||

| 2.3 | 300 | 300 | 300 | 300 |

| 2.5 | 230 | 230 | 230 | 230 |

| 2.8 | 150 | 150 | 150 | 150 |

| 3.2 | 110 | 110 | 110 | 110 |

*1:(Pneumatic):Option in case of pneumatic mandrel expansion is

provi

![]()