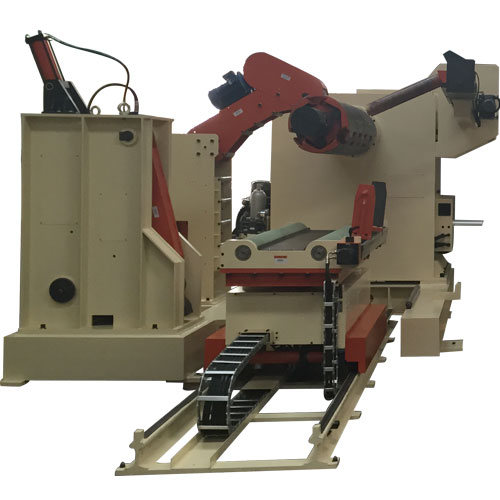

GUANGDONG RUIHUI INTELLIGENT TECHNOLOGY CO., LTD. |

|

High-speed roller feeder installation method:

Precautions for trial installation:

1. Adjust the feeding height of the high-speed feeder and the height of the mold material line.

Adjustment method: first loosen the fixing screw of the feeder,

rotate the adjusting screw up and down to the required position,

and then lock the fixing screw.

2. After adjusting the height of the feeder, it is necessary to

determine whether the rocker is horizontal when the punch is dead

(ie, whether the upper and lower swing angles are the same). If the

horizontal error is large, the pull nut is loosened and the rotary

lever is adjusted to the rocker level.

3. When punching thin materials, if there is still a certain distance between the

pressure plate and the lower mold, the guiding device must be made

again so as not to bend the material.

4. the mold should be fixed with the roller 90 degrees, otherwise

the material will be skewed, the feed has resistance, the pressure

is not even, causing the length of the delivery is not the same.

Roller feeder thickness adjustment:

Pull the loose handle up, place the material between the upper and

lower wheels, lower the release handle, and then loosen the

thickness adjustment plate fixing screw.

Move the material thickness adjustment plate handle up and down,

let the relaxation bracket swing about 5mm left and right, and then

lock the material thickness adjustment plate fixing screw.

The tightness and feeding time of the high-speed feeder press spring:

1. The function of the pressure spring is to apply pressure to the

upper wheel, so that the upper wheel can press the material and

send the material out, and the material must not be slipped as a

principle.

2. the feeding time is controlled by the eccentric disk, generally

normal is from 9 points (270 degrees) -3 points (90 degrees) Note:

The feeding time can be freely adjusted according to customer

needs.

3. Relax the feed distance due to the set screw, and rotate the

adjustment screw to scribe the required feed distance on the

vernier scale.

Note: Stop the punch at the bottom dead center, draw a line on the

material, place the punch and then go to the bottom dead center. A

line is drawn on the material, and the measurement is repeated

several times. Then, the material is sent into the mold, and the

guide pin hole is punched when the punching machine moves, and then

the punching time is over 3 points.

Specification:

| Model | MAC2-400 | MAC2-500 | MAC2-600 | MAC2-800 | ||

| Stock Width(mm) | 50-400 | 50-500 | 50-600 | 50-800 | ||

| Stock Thickness(mm) | 0.3~3.2 | 0.3-3.2 | 0.3-3.2 | -3.2 | ||

| Max.Coil Weight(kg) | 3000 | 3000 | 3000 | 5000 | 5000 | 7000 |

| Max.Coil O.D.(mm) | 1200 | 1200 | 1200 | |||

| Coil I.D.(mm) | 8 | 8 | 508 | 508 | ||

| Feed Length(mm) | ~500* | ~500* | ~500* | ~500* | ||

| Max. Line Speed(m/min) | 16-24 | 16-24 | 16-24 | 16-24 | ||

| Work Roll Number(pieces) | upper 6 lower 5 | upper 6 lower 5 | upper 6 lower 5 | upper 6 lower 5 | ||

| Feed Roll Number(set) | 1 | 1 | 1 | 1 | ||

| Main Motor(kw) | AC2.9 | AC2.9 | AC4.4 | AC4.4 | ||

| Mandrel Expansion | hydraulic | hydraulic | hydraulic | hydraulic | ||

| Reel Motor(kw) | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 |

| Power(V) | 3 Phase 220V/380V/50HZ | |||||

| Operating Air(Mpa) | 0.49 | 0.49 | 0.49 | 0.49 | ||

Straigtening performance:

| tock Thicknees (mm) | Stock Width (mm) | |||

| 0.3 | 400 | 500 | 600 | 800 |

| 0.4 | ||||

| 0.6 | ||||

| 0.8 | ||||

| 1.0 | ||||

| 1.2 | ||||

| 1.4 | ||||

| 1.6 | 470 | 470 | ||

| 1.8 | 400 | 400 | ||

| 2.0 | 360 | 360 | ||

| 2.3 | 300 | 300 | 300 | 300 |

| 2.5 | 230 | 230 | 230 | 230 |

| 2.8 | 150 | 150 | 150 | 150 |

| 3.2 | 110 | 110 | 110 | 110 |

*1:(Pneumatic):Option in case of pneumatic mandrel expansion is

provi

![]()