GUANGDONG RUIHUI INTELLIGENT TECHNOLOGY CO., LTD. |

|

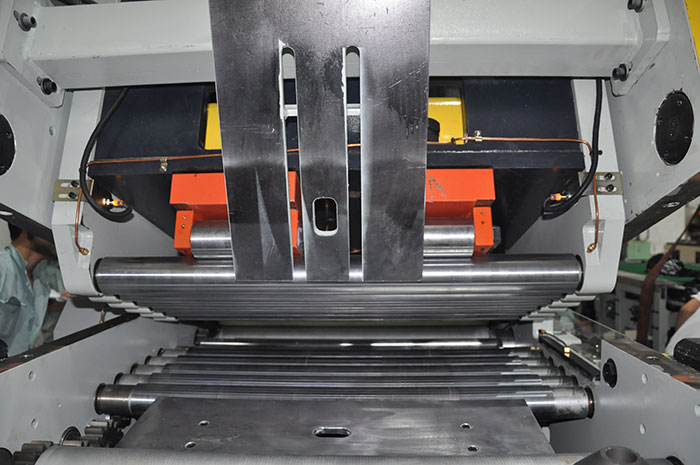

Material frame, machine to straighten wire, Ruihui automatic stamping equipment

Heavy-duty material frame is the most used material discharging and unwinding equipment in the stamping industry. It has been widely favored by stamping owners because of its large bearing capacity, wide application range, simple operation, stable performance, high degree of customization and affordable price.

Heavy-duty material racks can be used in a wide range of applications from tens of kilograms of lightweight coils to ultra-large coils weighing up to ten tons. It can be used for 24 hours with a stamping automation line consisting of a leveler, feeder and punch. Uninterrupted automated stamping production.

In the actual stamping production, in order to ensure the production efficiency, the stamping equipment is basically running without interruption, and the shifting is often only for people who do not stop the machine. Under such high-intensity work, the failure of the heavy material frame is inevitable.

Therefore, heavy-duty material rack operators must understand the causes and treatment methods of heavy-duty material racks in order to solve them in time to avoid affecting the entire stamping production.

Causes and solutions for mechanical failure of heavy material frame:

1. The actual coil material used in heavy material racks is beyond its scope of application. Heavy-duty material racks can be customized, but each manufactured rack has the maximum material thickness, width, material weight and outer diameter. If it exceeds its range of use, it will cause mechanical failure due to excessive load. It can be solved with a standard coil that meets the standard.

2. The spindle bearing of the heavy material coil is damaged and the equipment cannot be operated. The heavy-duty material frame needs to use the spindle to drive the tray to rotate and complete the unwinding action. If the spindle bearing is damaged, the machine will not be able to move. At this time, the spindle bearing can be replaced.

3. the heavy-duty material frame inside the fuselage belt is too loose, resulting in the slip can not provide normal power, the material frame back cover open, the drive belt can be tightened.

Specification:

| Model | MAC2-400 | MAC2-500 | MAC2-600 | MAC2-800 | ||

| Stock Width(mm) | 50-400 | 50-500 | 50-600 | 50-800 | ||

| Stock Thickness(mm) | 0.3~3.2 | 0.3-3.2 | 0.3-3.2 | -3.2 | ||

| Max.Coil Weight(kg) | 3000 | 3000 | 3000 | 5000 | 5000 | 7000 |

| Max.Coil O.D.(mm) | 1200 | 1200 | 1200 | |||

| Coil I.D.(mm) | 8 | 8 | 508 | 508 | ||

| Feed Length(mm) | ~500* | ~500* | ~500* | ~500* | ||

| Max. Line Speed(m/min) | 16-24 | 16-24 | 16-24 | 16-24 | ||

| Work Roll Number(pieces) | upper 6 lower 5 | upper 6 lower 5 | upper 6 lower 5 | upper 6 lower 5 | ||

| Feed Roll Number(set) | 1 | 1 | 1 | 1 | ||

| Main Motor(kw) | AC2.9 | AC2.9 | AC4.4 | AC4.4 | ||

| Mandrel Expansion | hydraulic | hydraulic | hydraulic | hydraulic | ||

| Reel Motor(kw) | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 |

| Power(V) | 3 Phase 220V/380V/50HZ | |||||

| Operating Air(Mpa) | 0.49 | 0.49 | 0.49 | 0.49 | ||

Straigtening performance:

| tock Thicknees (mm) | Stock Width (mm) | |||

| 0.3 | 400 | 500 | 600 | 800 |

| 0.4 | ||||

| 0.6 | ||||

| 0.8 | ||||

| 1.0 | ||||

| 1.2 | ||||

| 1.4 | ||||

| 1.6 | 470 | 470 | ||

| 1.8 | 400 | 400 | ||

| 2.0 | 360 | 360 | ||

| 2.3 | 300 | 300 | 300 | 300 |

| 2.5 | 230 | 230 | 230 | 230 |

| 2.8 | 150 | 150 | 150 | 150 |

| 3.2 | 110 | 110 | 110 | 110 |

*1:(Pneumatic):Option in case of pneumatic mandrel expansion is

provi

![]()