GUANGDONG RUIHUI INTELLIGENT TECHNOLOGY CO., LTD. |

|

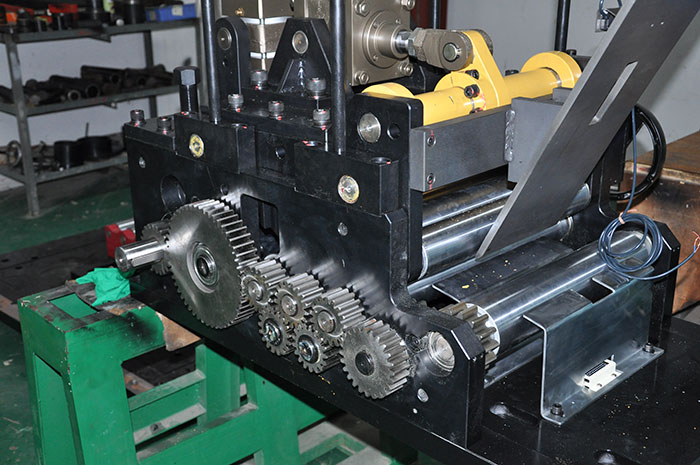

NC Feeder Decoiler And Straightener Hardware Car Sheet Metal Stamping Automation

In the precision manufacturing industry, the performance of a piece of equipment depends not only on the large parts, but on the overall size of each small part and whether it can be refined. The same is true for the production of NC feeders.

In the development, production and manufacture of NC feeders, compared with core components such as servo motors, PLCs, timing pulleys, and feed rollers, eccentric sleeves and bearings are often small in size and are often used in the design and manufacture of feeders. Did not attract attention.

However, the NC feeder is a high-end refining equipment. Although the spare parts are small, the role played by the whole machine cannot be ignored. It is often a spare part that affects the overall performance of the entire NC feeder.

In order to achieve the fastest and most accurate feeding function of the NC feeder, the rational design and installation of the spare parts is an indispensable part. If not, it will directly affect the operation of the whole machine, and even cause serious punching errors. Rushing, damaging the mold, causing personal injury and so on.

Many people may think that this is a big problem, but the role of these parts can not be ignored, such as eccentric sleeves, bearings they look small, but they play the role of a fixed feeding roller, many manufacturers of feeder manufacturers The eccentric sleeve is often overlooked when designing the feeder.

The roller is directly fixed by the bearing. In the actual use process, the thickness of the customer is often thick, and the output of the drum is large, and the left and right sliding, and finally the bearing is worn out, which affects the actual production of the customer.

Some manufacturers who have designed eccentric sleeve installations often do not emphasize the adjustment of the eccentric sleeve when the feeder is assembled. As a result, there is still some clearance after the upper and lower feed rollers are clamped on the side, which directly causes the feed to be inaccurate. The phenomenon of precision deviation.

Therefore, in the process of development, production and manufacturing of the feeder, any small link can not be ignored. It is these small deviations that determine the quality of the NC feeder.

Products:

Specification:

| Model | MAC2-400 | MAC2-500 | MAC2-600 | MAC2-800 | ||

| Stock Width(mm) | 50-400 | 50-500 | 50-600 | 50-800 | ||

| Stock Thickness(mm) | 0.3~3.2 | 0.3-3.2 | 0.3-3.2 | -3.2 | ||

| Max.Coil Weight(kg) | 3000 | 3000 | 3000 | 5000 | 5000 | 7000 |

| Max.Coil O.D.(mm) | 1200 | 1200 | 1200 | |||

| Coil I.D.(mm) | 8 | 8 | 508 | 508 | ||

| Feed Length(mm) | ~500* | ~500* | ~500* | ~500* | ||

| Max. Line Speed(m/min) | 16-24 | 16-24 | 16-24 | 16-24 | ||

| Work Roll Number(pieces) | upper 6 lower 5 | upper 6 lower 5 | upper 6 lower 5 | upper 6 lower 5 | ||

| Feed Roll Number(set) | 1 | 1 | 1 | 1 | ||

| Main Motor(kw) | AC2.9 | AC2.9 | AC4.4 | AC4.4 | ||

| Mandrel Expansion | hydraulic | hydraulic | hydraulic | hydraulic | ||

| Reel Motor(kw) | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 |

| Power(V) | 3 Phase 220V/380V/50HZ | |||||

| Operating Air(Mpa) | 0.49 | 0.49 | 0.49 | 0.49 | ||

Straigtening performance:

| tock Thicknees (mm) | Stock Width (mm) | |||

| 0.3 | 400 | 500 | 600 | 800 |

| 0.4 | ||||

| 0.6 | ||||

| 0.8 | ||||

| 1.0 | ||||

| 1.2 | ||||

| 1.4 | ||||

| 1.6 | 470 | 470 | ||

| 1.8 | 400 | 400 | ||

| 2.0 | 360 | 360 | ||

| 2.3 | 300 | 300 | 300 | 300 |

| 2.5 | 230 | 230 | 230 | 230 |

| 2.8 | 150 | 150 | 150 | 150 |

| 3.2 | 110 | 110 | 110 | 110 |

*1:(Pneumatic):Option in case of pneumatic mandrel expansion is

provi

![]()