Shenzhen Go-Gold Motor Co., Ltd. |

|

Verified Suppliers

|

|

Product Description

| Continuous Current | 0.7-2.4A | Rated Power | Customized |

| Rated Speed | 1-500RPM | Rated Voltage | 12V |

Lead Time

| Quantity | 1-1000 | 1001-10000 | ≥10000 |

| Lead days | 15 | 30 | To be negotation |

Essential Details

Application: Electrical Tools

Model Number: KG-2857GM12

Warranty: 3 Years

Rated Power: Customized

Key Word: Gear Motor

Rated Speed: 1-500RPM

Stall Current: 2.7A-15.0 A

Rated Torque: 0.64-30kg.cm

Place of Origin: Guangdong, China

Rated Voltage: 12V

Rated Power: 2.05W

Continuous Current: 0.7-2.4A

Efficiency: 78%

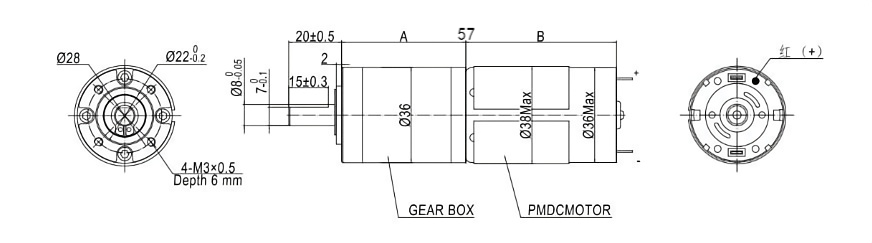

Size: 36*93mm

Drawing

Sample

Application

Motors can be constructed in several different physical configurations. In the conventional (also known as inrunner) configuration, the permanent magnets are part of the radially center core. In the outrunner (or external-rotor) configuration, the radial-relationship between the coils and magnets is reversed. The stator coils in the outrunner configuration form the center core of the motor, while the permanent magnets spin within an overhanging rotor which surrounds the core.

A gearmotor (or geared motor) is a small electric motor (AC induction, permanent magnet DC, or brushless DC) designed with an integral (non-separable) gear reducer (gearhead) attached.

The end shield on the drive end of the motor is designed to provide a dual function. The side facing the motor provides the armature/rotor bearing support and a sealing provision through which the integral rotor or armature shaft pinion passes. The other side of the motor end shield provides multiple bearing supports for the gearing itself, and a sealing and fastening provision for the gearhousing.

Significance Of Back EMF

When the motor is operating then the concept of generator comes into the picture i.e., whenever the flux linking with the conductor changes then there will be an induced emf in the conductor. Here, the flux produced by the poles will be stationary and constant and because of the motor principle, the armature starts rotating.

Because the armature starts rotating the flux produced by the main field will be cut by the armature conductor and therefore there will be an induced emf in the armature conductor according to the generator principle.

We know that the direction of the induced emf produced by the motor is opposite to the applied voltage. But the magnitude of the induced emf will be similar to that of the induced emf of the generator.

Summarize