Warranty:3years

Place of Origin:Guangdong, China

Brand Name:Go-Gold

Model Number:KG-3160

Usage:BOAT, Car, Electric Bicycle, FAN, Home Appliance, Cosmetic

instrument, SMART HOME, Electric Fan

Type:Brushless Motor

Torque:Customised

Construction:Permanent Magnet

Commutation:Brushless

Protect Feature:Totally Enclosed

Speed(RPM):18000RPM

Continuous Current(A):Customised

Efficiency:Other

Product Name:Brushless Dc Electric Motor

Motor type:BLDC Brushless Motor

Certification:CCC Ce RoHS

Rated Voltage:24V/custom Made

Keywords:Brushless Electric Motor

Noise:Low

Material:Cooper Wire

Weight:0.5kg

Rated Speed:Load Speed 18000rpm

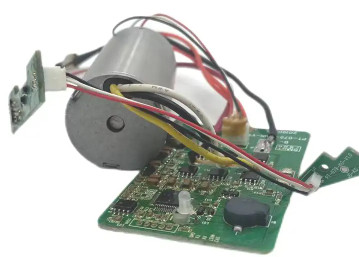

Product picture

Operational principle

Brushed DC motors use semiconductor switching devices to achieve

electronic commutation, which replaces traditional contact

commutators and brushes with electronic switching devices. It has

the advantages of high reliability, no commutation sparks, and low

mechanical noise, and is widely used in high-end recording

consoles, video recorders, electronic instruments, and automated

office equipment.

A brushless DC motor is composed of a permanent magnet rotor, a

multipole winding stator, a position sensor, etc. Position sensing

commutates the current of the stator winding in a certain order

according to the changes in rotor position (that is, detects the

position of the rotor magnetic pole relative to the stator winding,

and generates a position sensing signal at the determined position.

After being processed by the signal conversion circuit, the power

switch circuit is controlled to switch the winding current

according to a certain logical relationship). The working voltage

of the stator winding is provided by an electronic switch circuit

controlled by the position sensor output.

There are three types of position sensors: magnetic sensitive,

photoelectric, and electromagnetic.

Brushless DC motors using magnetic sensitive position sensors have

magnetic sensor components (such as Hall elements, magnetic diodes,

magnetic transistor, magnetic resistors, or specialized integrated

circuits) installed on the stator components to detect changes in

the magnetic field generated by the rotation of permanent magnets

and rotors.

A brushless DC motor using photoelectric position sensors is

equipped with photoelectric sensor components at certain positions

on the stator assembly, a light shield is installed on the rotor,

and the light source is a light-emitting diode or small light bulb.

When the rotor rotates, the photosensitive components on the stator

will intermittently generate pulse signals at a certain frequency

due to the effect of the shading plate.

A brushless DC motor using electromagnetic position sensors is

equipped with electromagnetic sensor components (such as coupling

transformers, proximity switches, LC resonant circuits, etc.)

installed on the stator assembly. When the position of the

permanent magnet rotor changes, the electromagnetic effect will

cause the electromagnetic sensor to generate high-frequency

modulation signals (whose amplitude changes with the rotor

position).