Suzhou Tongda Machinery Co., Ltd. |

|

Lubricating Oil Bottle Jerry Can Making Machine High Speed Servo System EBM Extrusion Blow Molding Machine

Product Description of our HSII-12L Extrusion Blow Molding Machine

HSII-12L model machine is our high level series extrusion blow molding machine. It is double station, with servo motor for hydraulic system to save energy. Now equipped with double die head, producing the 4L lube oil jerry can, with double die head, can produce max 5L HDPE jerry cans, if equipped with single die head, is suitable to produce max 12L HDPE jerry cans. To meet customers' different requirement, also can be equipped with triple die head, four die head, six die head, and can also equip multi layers, liquid level line screw,

If equipped with robot arms or 3Dimensional robot arms, conveyors, leak tester, IML in mold labeling machine, the automation will be upgraded.

Technical Parameters our HSII-12L Extrusion Blow Molding Machine

MODEL | Units | HSll-12L | Remarks: we will customize the most suitable machinery according to

your requirements |

Max. Product volume | L | 12 | |

Output of HDPE | kg/h | 180 | |

Clamping force | kn | 158 | |

Screw diametre | mm | 100 | |

Screw heating power | kw | 21 | |

Blow pressure | mpa | 0.6 | |

Size of machine | m | 4.9*3.1*3.2 |

Product Details our HSII-12L Extrusion Blow Molding Machine

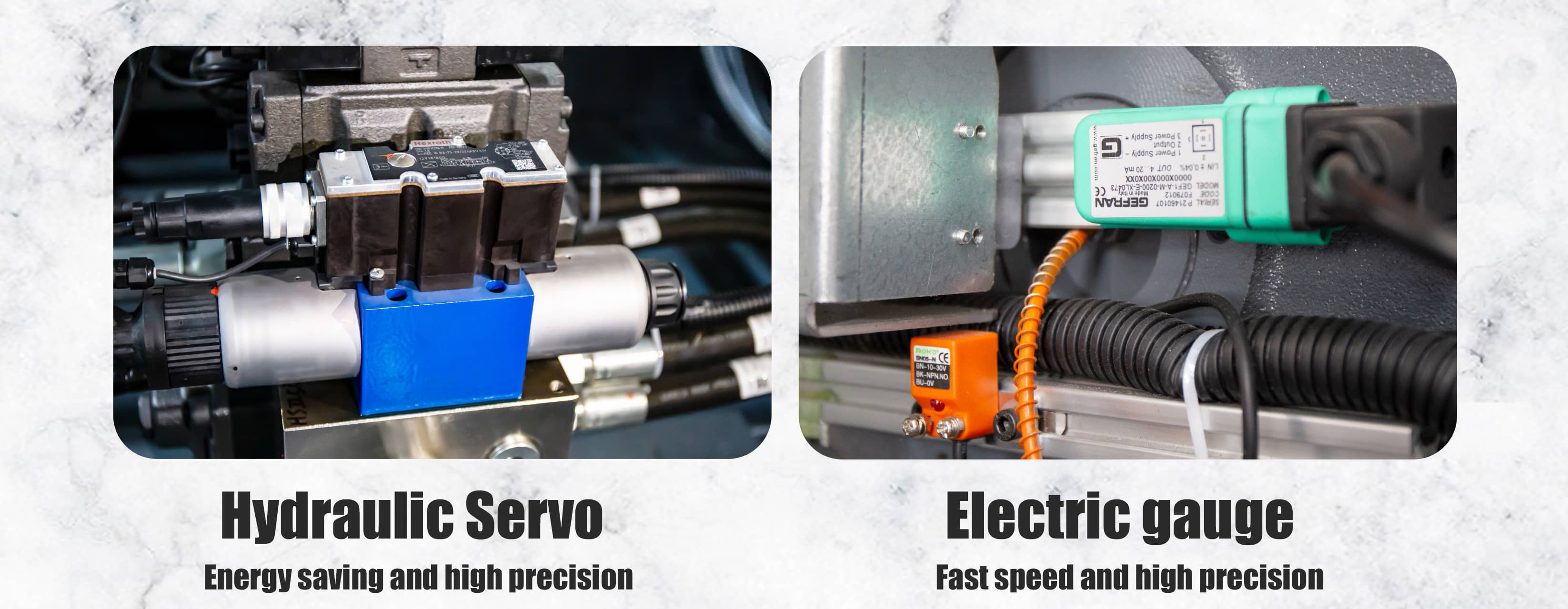

Hydraulic Servo:Energy saving and high precision

Electric gauge:Fast speed and high precision

Company Information

"Working Together to Grow Together" is the spirit of Suzhou Tongda Machinery, to cooperate with us and we are always at your service to provide you with strong support.

Service Network

We have normal spare parts in our ware house, not only electrical parts, but also mechanical spare parts. It helps us deliver the spare parts customers need promptly.

FAQ

TONGDA sales consultant

1. We can provide comprehensive and professional Suggestions on

equipment selection.

2. Energy consumption calculation and investment income analysis

can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product

optimization Suggestions.

4. Extrusion plastic bottle blow molding machine has remote

maintenance function

Advantages of TONGDA after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of

auxiliary equipment.

5. A free 2-day training course will be provided to customers every

year.

6. Special processing equipment to produce after-sales accessories

to ensure rapid response to user needs.