Suzhou Tongda Machinery Co., Ltd. |

|

Product Description

Technical Parameters

MODEL | Units | TDB-50F | Remarks: If you have other special requirements,we can provide

customized services for you. |

Max. Product volume |

L | 50 | |

Output of HDPE | kg/h | 130/160 | |

Clamping force | kn | 260 | |

Screw diametre | mm | 90 | |

Screw heating power | kw | 17.4 | |

Blow pressure | mpa | 0.6 | |

Size of machine | m | 5-*2.4*3.8 |

Patented product: Two tie rods, single cylinder bidirectional synchronous mold opening and closing center mold clamping mechanism, which makes product quality stable and this design easy to take out the product.

Low energy consumption:If the screw speed of TDB-50F is around 70%, then the average power consumption is 35KW/h

Die head:Excellent flow channel technology and precise machining accuracy, make the color change and material change more efficient. From dark to white, normally can be completed within 3hours. Much quicker than other suppliers. Save cost for you if you need to produce different color products.

Linear guide rails with high quality, so with high running accuracy and longer service life.

Company Information

"Working Together to Grow Together" is the spirit of Suzhou Tongda Machinery, to cooperate with us and we are always at your service to provide you with strong support.

Our company have a service team with 35 qualified engineers can fly overseas to do the installation and commissioning.

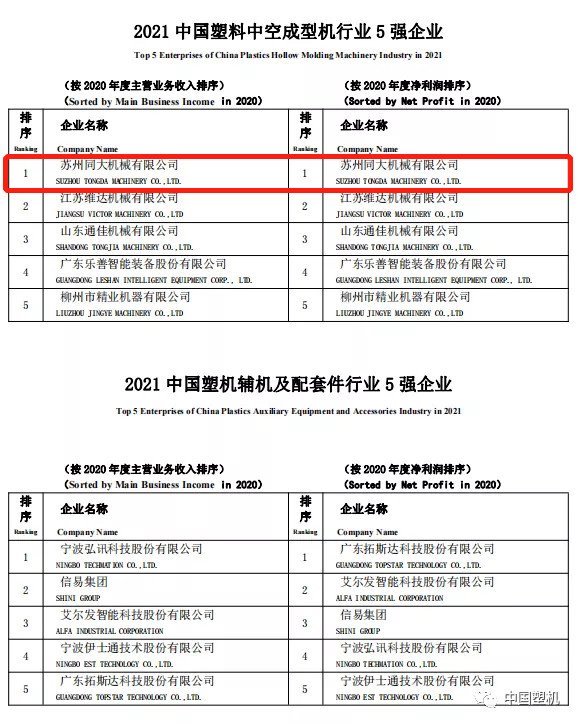

Suzhou Tongda Machinery has won TOP 1 in China domestic extrusion blow molding machine for continuous 10 years.

After-sales Service

Why Choose Us