Xinxiang Haishan Machinery Co., Ltd. |

|

Supplying C90500 high density tin bronze different specifications copper wear plate

Product introduction

| Material | Brass,Tin bronze,Lead bronze,Aluminum bronze, etc |

Feature | 1. High load capacity Good anti-wearing |

| 2. Low coefficients of friction | |

| 3. Good heat conductivity | |

| 4. High corrosion resistence | |

| 5. Long life and maintenance-free | |

| 6. No contaminant by oil or grease | |

Process | Centrifugal casting,Sand casting,Machining,Injection |

| OEM Service | Yes |

| Payment | T/T, L/C, Western Union, Ali credit insurance, Paypal |

| Port | QINGDAO ,TIANJIN ,SHANGHAI ,NINGPO PORT |

| Drawing | Yes |

| Sample | Available |

| MOQ | 50kg |

| Lead time | According to required time |

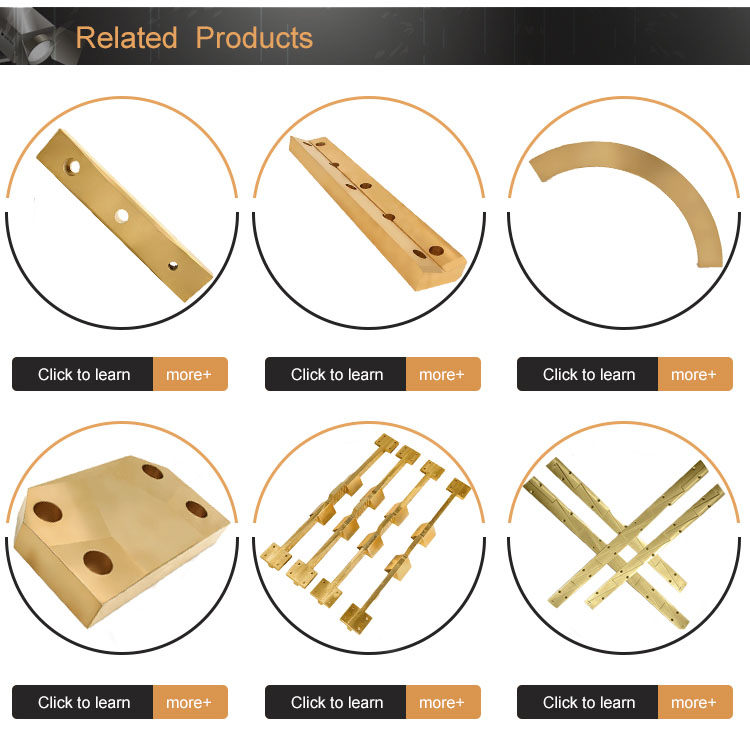

Related products

Company information

XinXiang HaiShan Machinery Co.,Ltd. Is manufacturer specializes in production and processing of copper parts,with lathing milling planing grinding gear hobbing stamping process

At present, mainly engaged in tin bronze alloy; copper sleeve accessories of cone crusher; aluminum bronze alloy; shaft sleeve; copper plate; copper bushing; copper alloy cone sleeve; copper horizontal sleeve; copper alloy bearing bush; copper bowl type bush; Copper sleeve. Production and processing of all kinds of mechanical copper alloy, aluminum alloy accessories and other general parts, and can customize all kinds of accessories according to the customer's drawings or real sample requirements; the company adopts centrifugal casting, sand casting, steel casting and other casting methods, precision CNC lathe processing and production

Applicable Industries

Applied in: diesel engine, automobile, agricultural machinery, hydraulic machinery, machine tools, forestry machinery, construction machinery, mining, railway, ship, petrochemical machinery, die-casting machine, metallurgical equipment; food packaging machinery, textile, light industrial machinery and aviation, weapons and other industries and departments of various machines, Mechanically

Features:

1. Wear resistance: The wear resistance of the wear plates is better. The wear plates of different materials have different characteristics. The inner structure of the centrifugally cast wear plates is relatively close, and there will be no loosening and pore trachoma. The hardness of the centrifugally cast wear plates is relatively high and durable.

2. Corrosion performance : This is another characteristic of the wear plates, which has good corrosion performance. It is mainly used in atmosphere and fresh water. In the process of using the wear plates, it is not easy to bite to death. The corrosion resistance of the wear plate is mainly reflected in some chemical elements, such as dilute sulfuric acid, hydrochloric acid and fatty acid. Therefore, the corrosion resistance of the wear plates is very good, it will not produce bite situation mainly because of its own characteristics, even if there is no lubricant, it can still work normally.

3. Compression resistance: The wear plates has good compression resistance, especially the surface pressure is very high, it can withstand the side pressure of the bearing. Under the condition of high load pressure, the wear plates can also be operated.

Packing&Shopping

Export packing in wooden case:

1. Plastic bags wrapped

2. Bubble paper / Pearl cotton wrapped

3. Durable wooden carton / box

4. Foam plate in the bottom

FAQ

2. Q: How to visit your factory?

A: Our company is located in Xinxiang Henan prov.China. welcome everyone from home and abroad to visit.

3. Q: Why should i choose you?

A:A Passion--- With a young and vibrant team can keen eye to focus

on your needs

B.Professional --- With advanced casting technology,sand casting /centrifugal casting /metel casting to meet different client's product requirpment

C.Patiently---- All the custom machined bushings can be produced by the drawings,sketchers, also we provide drawing design based on the request

4. Q: How do you control the quality?

A: We have a series of testing equipment such as Chemical

Composition Analyser,Hardness tester,DYE Penetration

Inspection,Ultrasonic Testing,

Also we support the quality test by the 3rd Party like SGS

5. Q:How long is the lifetime of these bushings?

A:Normaly 3-5 years according to the diffirent working

environment.With gentle care they can help your machine output

more,

6. Q: Can you give me a discount?

A:We believe quality equal the price. As we all know the larger

quantity orders, the more discount.

7. Q: How about your after-sale service and the problmes repsonse speed ?

A:We are responsible for every sold product.If there any problems please take pictures and count the quantities,will feedback solutions and PAR Preventive Action Report to you within 12 hours.

8. Q:What about the payment terms?

A:We'd like to hear customers' opinion, Normally payment terms as

below

A. 50% T/T in advance the balance before ship

B. 100% L/C at sight

C. Paypal (small purchase)

D. Ali Trade assurance payment on line by the credit card