Guangzhou Jingyijin Machinery Equipment Co., Ltd |

|

Verified Suppliers

|

|

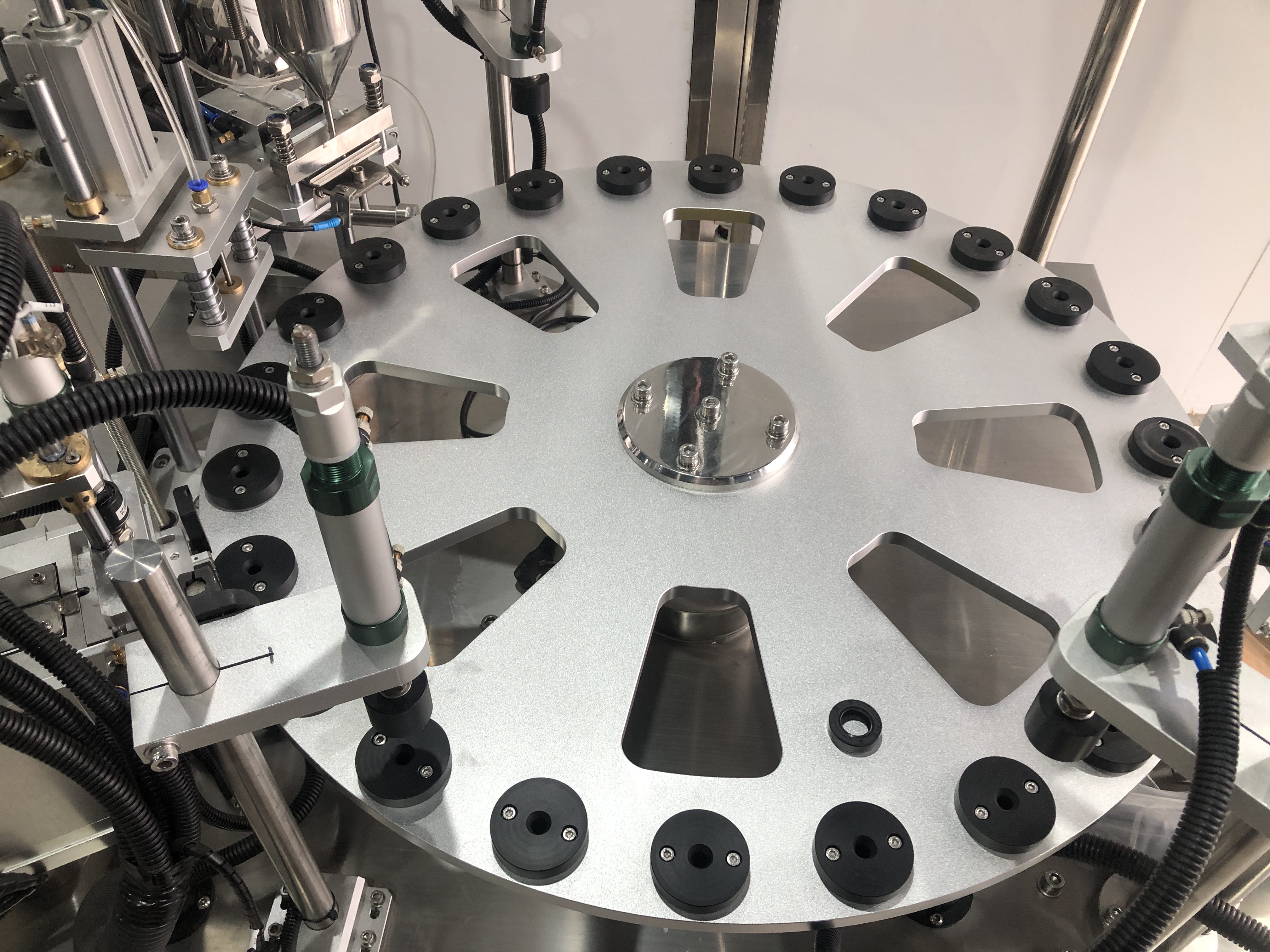

This machine is suitable for water-based eyeliner products with steel ball. It is characterized by fast filling speed, accurate dosing, high qualification rate, easy operation and easy cleaning.

Technical Parameters:

|

Advantages:

We have a high-quality team that can provide professional services for our customers.

Uses and function:

1.machine process consists of manual tube release-automatic correction-automatic filling-filling steel ball-filling-vibrating cap-automatic capping-clamping out finished products and other processes. The processes are controlled and debugged independently and separately;

2.machine filling adopts servo quantitative filling system, accurate quantitative. The nozzle has a suction device, which will not leave any residual material, and the dosing valve and pipeline are easy to change and clean.

3.correction, pressure adjustable at the pressure cap, suitable for different heights, different materials, different elasticity of the package lid;

4.adopts PLC program control, the set parameters (dosing, time, temperature control settings) are set by the PLC interface, can accurately set the filling capacity, for multiple types and diversified users with great practicality and benefits

Detailed drawing:

Packing :