Guangzhou Jingyijin Machinery Equipment Co., Ltd |

|

Verified Suppliers

|

|

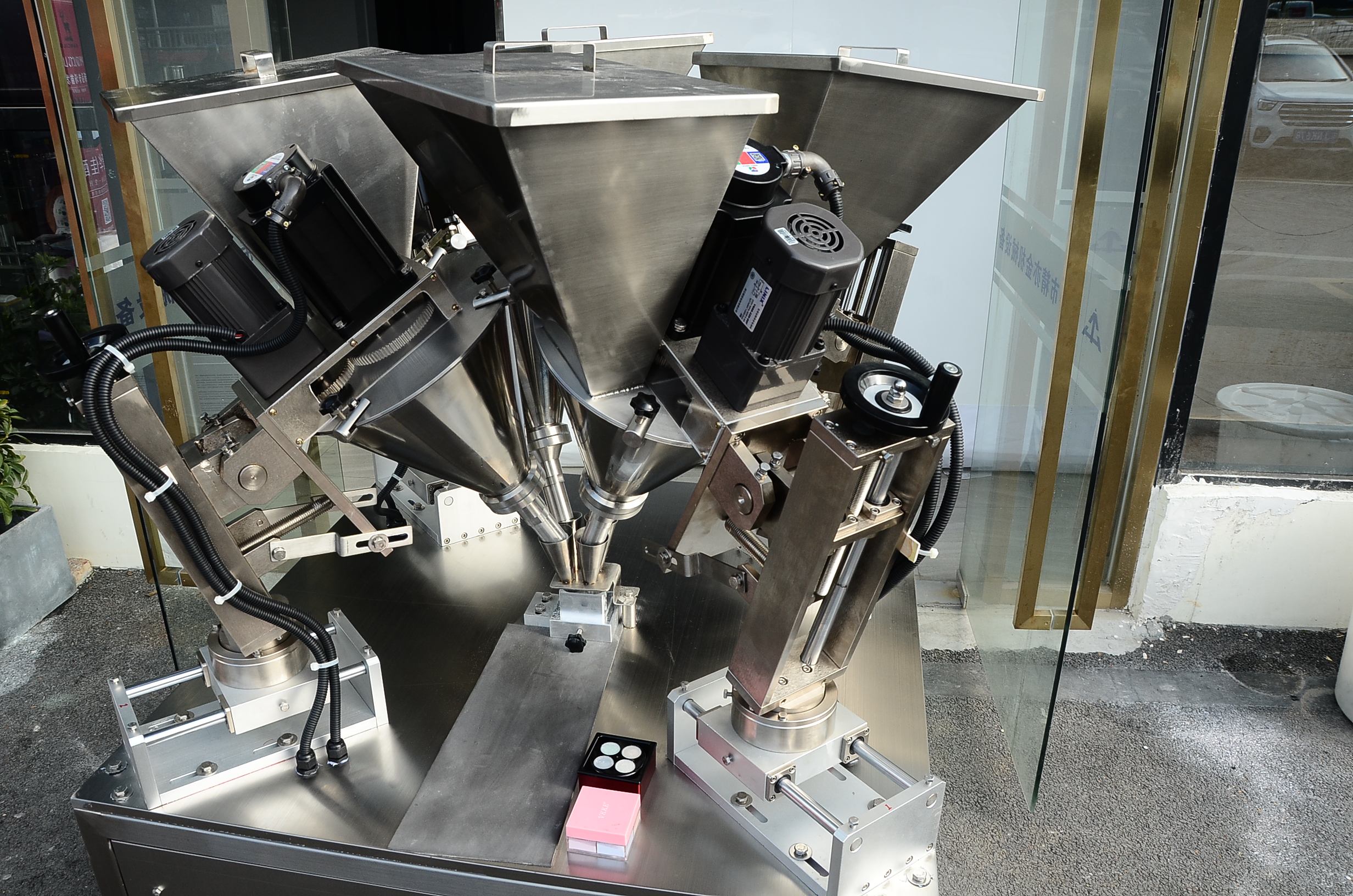

Powder Production Line Four-Color Powder Filling Machine 220V /

50-60Hz Loose Powder

Description:

1. Application: In food, chemical industry and pharmaceutical

products, powder type and small particle objects can be filled,

suitable for eye shadow powder, prickly heat powder, perfume

powder, all kinds of powder, etc.

2. Using screw filling and PLC control, man-machine interface

operation, stepper motor drive, with accurate filling volume, high

stability and very low failure rate

3. The touch screen is made of Taiwan Weilong. Control panel uses

PLC display for convenient setting of filling and quantitative

parameters

4. Material barrel belt stirring, the speed is adjustable. The

contact material part of the feeding mechanism is made of imported

SUS304 stainless steel

5. The filling nozzle of the powder bucket can rise and drop by 360

degrees according to the Angle of the hole of the packing box (up

and down range: 20-30cm). Operation, color change, easy

maintenance, less fault.

Quick Details:

1. Container Placement: Empty containers, such as bottles, jars, or

pouches, are positioned or conveyed to the filling machine. The

containers are typically held securely in place to ensure accurate

filling.

2. Powder Supply: The machine is equipped with a powder supply

system, usually a hopper or reservoir, where the powdered substance

is stored. The hopper can be manually loaded or connected to a

powder handling system for automated feeding.

3. Filling Mechanism: The key component of a screw powder filling

machine is the rotating auger screw. The screw is made up of a

helical blade that rotates within a tube or nozzle. The rotation of

the screw transports the powdered substance from the hopper to the

discharge point.

4. Filling Process: As the auger screw rotates, the powdered

substance is drawn into the flights of the screw and conveyed

toward the discharge point. The rotation speed of the screw can be

adjusted to control the flow rate and achieve the desired filling

volume.

5. Discharge and Control: At the discharge point, the powdered

substance is dispensed into the containers. The machine typically

includes mechanisms to control the flow rate and cut-off the powder

flow accurately, ensuring precise filling.

6. Leveling and Settling: Some screw powder filling machines may

incorporate leveling or settling mechanisms to ensure uniformity

and proper density of the filled product. These mechanisms can help

achieve consistent fill levels and minimize air pockets or voids in

the powder.

7. Container Closure: Once the powder filling process is complete,

the filled containers are typically transferred to the next stage

of the packaging line for closure, such as capping, sealing, or

labeling.

Specification:

| Supply voltage | 220V/50-60Hz |

| Power of motor | 60W * 4 |

| Subscription range | 1-25G (Single filling nozzle) |

| Production capacity | 15000-18000 units / day (by gram and powder) |

| Bucket capacity | 20L * 4 |

| External size | 1000*1000*1750mm (L*W*H) |

| Table height | 940mm |

| Net weight | 200kg |

| Filling error | ±1% filling 1-10 g powder (accurate to 0.1 g) |

Advantages:

We have a high-quality team that can provide professional services for our customers.

detailed drawing: