Cangzhou Kading Carton Machinery Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

Folding gluing machines have become indispensable in the packaging industry, offering efficient and precise solutions for folding and gluing corrugated cartons. Understanding the correct usage method, working principle, and necessary precautions is essential for maximizing the machine's performance and ensuring optimal results. In this article, we will explore the usage method, working principle, and precautions associated with these machines.

| Max.size(A+B)x2 | 2600mm | Min.length A | 170mm |

| Min.size(A+B)x2 | 600mm | Max.height D | 900mm |

| Max.size(C+D+C) | 1200mm | Min.height D | 150mm |

| Min.size(C+D+C) | 270mm | Max.tongue width E | 40mm |

| Max. rock cover C | 60mm | Max feeding height | 900mm |

| Min rock cover C | 380mm | Max.length A | 770mm |

| Max width B | 530mm | Min.width B | 130mm |

| Working speed (nail/min) | 800mm | Nail number | 1-99 |

*Machine's specification is subject to the final confirmation of seller and buyer.

Usage Method of Folder Gluer Machine

Preparation: Start by selecting the appropriate machine settings based on the carton dimensions and desired folding and gluing configurations. Ensure that the machine is properly cleaned and any residual glue or debris from previous operations is cleared.

Loading: Place the pre-cut carton blanks onto the feeder of the machine, ensuring proper alignment and positioning. Adjust the guides and side fences to secure the cartons and prevent misalignment during the folding and gluing process.

Adjustment: Fine-tune the machine settings, including folding parameters, glue application areas, and compression settings, to match the specific requirements of the cartons being processed. Make necessary adjustments to ensure accurate folding and precise glue application.

Operation: Start the machine and monitor the folding and gluing process closely. Ensure that the cartons are folded correctly, and the glue is applied uniformly and accurately. Address any issues or misalignments promptly to maintain production efficiency.

Working Principle of Folder Gluer Machine

Corrugated carton folding gluing machines operate based on a few key principles:

Feeding and Alignment: The machine's feeder system ensures a continuous supply of carton blanks, feeding them into the folding section in a controlled manner. Guides and side fences assist in aligning the cartons for precise folding and gluing.

Folding: The machine utilizes various mechanisms such as belts, suction cups, or mechanical arms to fold the carton flaps accurately. The folding process is driven by motors and controlled by the machine's settings and adjustments.

Gluing: The glue application system applies adhesive to specific areas of the carton, typically using rollers or nozzles. The system ensures uniform glue coverage, providing strong and reliable bonding between carton surfaces.

Precautions

To ensure safe and efficient operation of corrugated carton folding gluing machines, the following precautions should be taken:

Safety Measures: Operators should receive proper training on machine operation and safety protocols. Adhere to all safety guidelines, including wearing appropriate personal protective equipment (PPE) and ensuring the machine is properly guarded.

Maintenance: Regular maintenance and cleaning of the machine are essential for optimal performance. Follow the manufacturer's recommendations for routine maintenance tasks such as lubrication, belt tensioning, and cleaning of glue application components.

Material Compatibility: Ensure that the carton material used is suitable for the machine's folding and gluing processes. Incompatible materials can result in subpar folding, glue adhesion issues, and potential machine damage.

Quality Control: Implement quality control checks throughout the production process to verify the accuracy of folding, glue application, and overall carton quality. Inspect cartons regularly to identify any defects or issues and address them promptly.

Conclusion

These machines offer efficient and precise solutions for folding and gluing corrugated cartons, streamlining the packaging process. By following the correct usage method, understanding the working principle, and implementing necessary precautions, businesses can maximize the machine's performance and ensure consistent production of high-quality cartons. Adhering to safety measures, conducting regular maintenance, using compatible materials, and implementing quality control checks are vital for safe and efficient operation. By utilizing them effectively, businesses can enhance their packaging capabilities and meet the demands of the ever-evolving packaging industry.

Choose Kading to provide you with the best machine purchase plan.

Automatic Folder Gluer Stitcher Machine Description

1. Suitable for 3 ply, 5 ply and 7 ply single-piece carton nailing and bonding;(for double pieces machine, please ask our sales for more details)

2. Nail pitch range: 40-500MM;

3. The nailing angle is 40 degrees;

4. Single and double nails can be adjusted freely, suitable for

international #17 and #18 nail wires;

5. Use the forearm sorting function to change the order quickly,

and the paper is in good order;

6. The wire feeding machine adopts intelligent wire feeding, which

has little wear on the wire wheel;

7. The computer system adopts servo motor to ensure the stable

operation;

8. The speed can reach 1050 nails/minute;

9. Low equipment failure rate (using soft bottom mold structure);

10. The swing nail head runs smoothly.

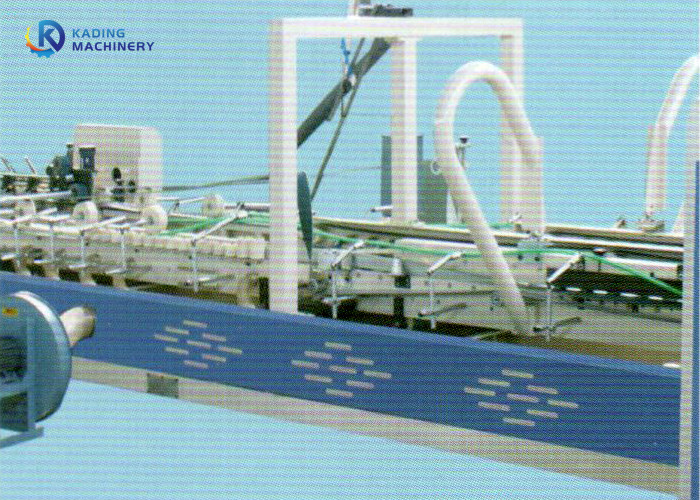

Paper Feeding Unit

Folding Unit

Stitching Unit

Stacking Unit

Cangzhou Kading Carton Machinery Manufacturing Co., Ltd's factory was founded in 2009 and is located

in Dongguang County, Cangzhou City, Hebei Province.

We are a manufacturing enterprise that produces carton making machinery, with 30 expereinced workers,

2 professional product tester, and 1 core skilled carton printer engineer; Besides, we also have a sales team

composed of a group of young people with forward thinking, we can make a professional product plan for you

according to your product needs.

Our company's self-produced product lines include carton printing machines, carton die-cutting machines,

and carton slotting machines; Our advantageous products include Carton stitching machines, Folder gluer

machines, Flute laminating machines, Single facer machines, etc.

If some related products you need are not produced by ourselves, with our mature product supply chain

system, we will also help you purchase products that satisfy you with the most competitive price and the

most guaranteed quality as the standard.

In addition to our own foreign trade business, our factory also cooperates with many trading companies,

so our products are exported to dozens of countries such as the Middle East, Africa, Southeast Asia, and

the European Union, and are well received by the majority.

There are also many brand&branded manufacturers among our customers, these factories are very relieved

to entrust the production of some products to us, which is enough to show that our quality and production

conditions are trustworthy.

Cooperate with us, benefit together!

Q: Are you a factory or a trading company?

A: We are a direct manufacturer that is located in Dongguang county,

Cangzhou city. Welcome to visit our factory!

We can also have video call if you’d like an online factory tour.

Q: How do you ensure your quality?

A: 1. Trustworthy and long-term cooperative raw material suppliers;

2. Skilled&experienced engineer&workers;

3. Mature QC system;

4. Specially-assigned merchandiser;

5. Advanced production workshop.

Q: How about your after-sale service?

A: 1. Special after-sale team will be 24/7 online;

2. Can guide the installation door-to-door;

3. One-year warranty for spare parts.

Q: How many languages does your machine support?

A: Our machine supports all the languages.

Q: How long it will take to produce machine?

A: Delivery time largely depends on the machine type, for some small

machine like manual stitching machine, manual

banding machine etc, usually we have stock available.

But for the large machines like carton printing die cutting

machine, automatic stitching machine etc, it usually takes

around 35-50 days to produce.

Q: Can we visit your factory?

A: Sure, welcome to pay a visit for our factory, we will pick you up

from airport, and will provide accommodation.