Cangzhou Gerun Machinery Co.,Ltd |

|

Verified Suppliers

|

|

Waste Carton Removal Flat Platen Die-cutting Die Cutting Machine Machine

| Introduction |

Waste Carton Removal Flat Platen Die-cutting Die Cutting Machine Machine can process flat paper,

cardboard and corrugated paper.

It is suitable for die cutting indentation and cold pressing of paper boxes, cartons, paper trademarks, etc.

In particular, all kinds of high-end and exquisite printed materials (such as cigarette boxes, wine boxes,

gift boxes, cosmetic boxes, etc.) can be die-cut and indented on this machine to obtain three-dimensional,

exquisite and beautiful packaging products.

This machine realizes the automation of the paper feeding, die cutting, and paper delivery processes.

Use the "human-machine interface" to display the machine's working speed, the number of processed

sheets, the total running time and working status of the machine; Realize dynamic monitoring of the

input points, output points and various faults of the programmable controller, so as to troubleshoot and

operate more convenient.

1.Suitable for different kinds of corrugated paper, strong

applicability. The special PU rubber wheel and suction trimming

device, to suit the request from F to 5 layer, the different

thickness of the corrugated paper. Make sure warp paper or thick

paper delivery smoothly.

2.Unique servo front edge feeding can be arbitrary regulatory

length. The papers can get the front lays smoothly by the

crankshaft paper speed reducer which is controlled by the servo

motor. To reducing destroy the strength of board. Conveying more

precisely. Laminating cardboard can be produced easily too.

3.PLC program control, safe and reliable 2. Electronic controlled

system adopts PLC program control. With various safety devices to

guarantee machine and human safety.

4.Monitor the machine state to display running status, trouble

location, troubleshooting and relevant help information.

5.Use the layer board to greatly improving productivity. With

photoelectric detector ensure running security and reliability and

collecting paper steady and fast.

6.The master driving chain adopts heavy-duty and high-precision

chains with length within close limit, high tensile strength, high

anti-abrasion.

| Parameters |

| Main technical specifications | |

| Max. paper size | 1320*980mm |

| Min. paper size | 350 x 450mm |

| Max. die-cutting size | 1300*960 mm |

| Feeding materials | 200~2000g/m²cardboard,corrugated paper board <8mm |

Min. Size in mouth | 8mm |

| Max. cutting speed | 5500sheets/hr |

| Max. die-cutting pressure | 350ton |

| Power required | 18kw |

| Compressed air pump | Air compressor discharge capacity 0.36m3 / min (cubic / minute) --- User-supplied |

| Power supply | 380V triple phase 50HZ |

| Net weight | 16.5ton |

| Dimensions | 6500x 2300 x 2346 mm(length x width x height) |

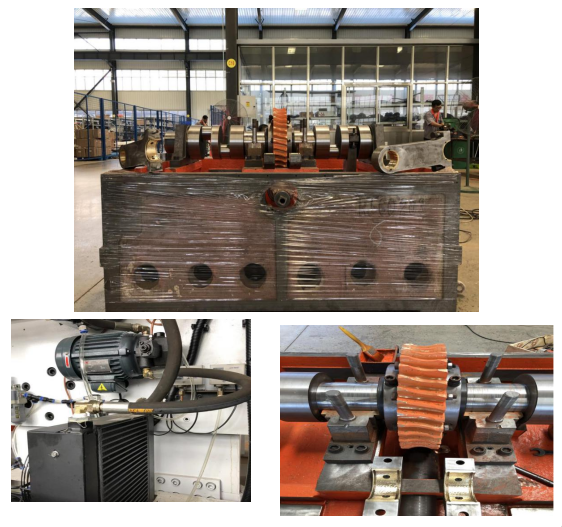

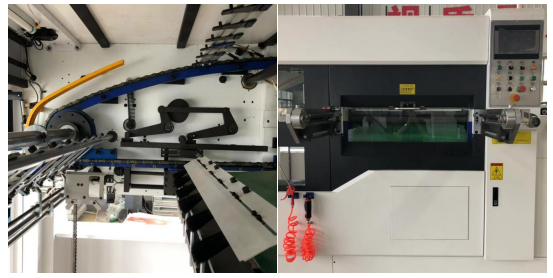

| Detailed Images |

|

|

|

Feeder feeding unit

Host machine unit

German IWIS chain & aviation aluminum tooth row

Die cutting unit

Waste remove unit(Optional)

Stacking unit

| FAQ |

1. Q: Are you a factory or trading company?

A: We are machinery manufacturer which is located in Cangzhou,Hebei

province,China.Cangzhou Gerun Machinery Co.,Ltd.

2. Q: How can I visit your factory?

A: We can pick you up from Beijing airport if you need,

welcome to visit our factory.

3. Q: What are your products?

A: We are specialized in producing 3ply, 5ply, 7ply corrugated

cardboard production line, high speed printing

machine, creasing and die cutting machine,folder gluer,flute laminator,stitching&strapping machine and other

corrugated cardboard production equipments.

4. Q: How does your factory do regarding quality controlling?

A: Over the years our company take “the quality first”

“integrity-based” corporate purpose always meet

users’ requirements as our sole purpose, providing the products with excellent quality, professional technology.

Always attach great importance to quality controlling from the very

beginning to the very end.

a. All spare parts we used are genuine.

b. Skillful workers care every detail in handling the producing and

packing process.

c. Quality control department especially responsible for quality in

each process.

d. The machine will be running more than 24 hours before shipping.

e. Each of our machine has its manufacture series number to track for long time.

| Packing and Shipping |

|

| Our Services |

| Factory |