Cangzhou Gerun Machinery Co.,Ltd |

|

Verified Suppliers

|

|

2000 Model Semi Automatic Single Piece Stitching Machine

| Introduction |

Function:

1. Can nail :single,double,strengthen the nail screw in one time.

2. Be suitable for the big carton,binding energy and fast.

3. In pieces size using automatic control,computer screen display and fault description.

4. Nail spacing: 0mm~120mm can be arbitrary regulation.

5. Full electric control pieces size used paper feeding unit adopts automatic counting.

6. Adjustment screw pitch,apply computer setting automatic nail spacing.

7. This transformation and adjustment of carton carton size from

the nail it takes only a minute to be completed, greatly saves time

and is convenient to operate.

8. The front feeding part automatically counting, the feeding table

is provided with a photoelectric sensing device, automatic rising

feeder.

9. This post with automatic counting function, finished cartons can

be set according to the number (1-99) sub stack sent to lose.

10. Send machine end, easy to pack up and bound.

11. Nail automatic alarm after line. (to avoid the non linear when

the leak to fight, less nail bad product)

12. From semi-finished stapled to the finished and packaged Banding

placed in the whole process of only two people operation, the

operation is simple and convenient for less pay.

Mechanical advantage:

1)Imports of dual-servo-driven precision , mechanical transmission part of the reduction can effectively reduce the mechanical failture rate .

2)Touch screen operation , parameters (Screw pitch , the number of nails , nail species , tailgate) transformation convenient .

3)Siemens PLC control system for the hole control system

4)After the electric tailgate , the use of stepper motor drive, accurate size , transform size is more concenient

Configuration:

The use of power: 12HP (Japan Yasukawa from serving motor)

Control box switch with all Taiwan Shilin production.

Switch $ button used in Taiwan plant.

Bearing used Japan brand.

ALL of the speed reducer adopts the production plant in Taiwan.

Nail head adopts a special tungsten steel production,computer high precision machining.

Ø Electric control machine cluch with alarm,when moving it will be alarm to make sure the safety.

Ø Transmission sharft with safety clutch,Avoid wrong actions and damage the machine.

Ø Pneumatic lock.

Ø Main motor with start protection device.

Vacuum suction type lead edge feeder system:

Ø Belower suction assist feed.Belower quantity can be adjustment.

Ø Frount flaper and back flaper adopt manual adjust the gap,feeder flaper electric adjust thegap.

Ø Feeder wheel adopt PU polyurethane,long using life.

Ø Stuiable for 3ply 5ply 7ply ,inclued E flute.

Ø With paperboard counting function.

| Parameters |

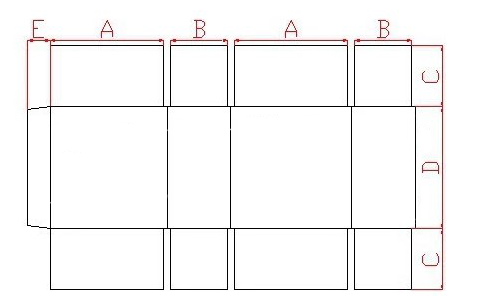

| type and the parameter | SC-2000 | SC-2400 | SC-3000 |

| max paper(A+B)*2(mm) | 4000 | 4800 | 6000 |

| min paper(A+B)*2(mm) | 1060 | 1060 | 1060 |

| A mmMax carton length | 2850 | 2850 | 2850 |

| A mmMix carton lengt | 350 | 350 | 350 |

| BmmMax width | 1000 | 1200 | 1500 |

| B mmMin width | 120 | 120 | 120 |

| (C+D+C)(mm)Max paper height | 2500 | 2500 | 2500 |

| (C+D+C)(mm)Min paper height | 400 | 400 | 400 |

| C(mm) | 560 | 560 | 560 |

| C(mm) | 50 | 50 | 50 |

| D(mm)Max height | 2000 | 2000 | 2000 |

| D(mm)Min height | 150 | 150 | 150 |

| (mm)Max tongue width | 45 | 45 | 45 |

| mm stitch distance | 30-120 | 30-120 | 30-120 |

| stitch No | 1-99 | 1-99 | 1-99 |

| speed (/mim) | 600 | 600 | 600 |

| (T)weight | 2.5 | 3 | 3.5 |

| Detailed Images |

|  |

|  |

1.Double servo drive, accurate accuracy, mechanical transmission part reduction, can effectively

reduce the mechanical failure rate.

2.Famous touch screen operation, parameters (nail distance, number of nails, nail type, back panel)

change is convenient and fast.

3.Rear electric baffle, driven by stepper motor, accurate size, more convenient and quicker to change size.

4.The full contactor in the control box is branded by Schneider.

5.The photoelectric and proximity switches are based on the Schneider brand.

6.The bottom mold, the blade is made of Japanese tungsten steel (wearable).

7.The whole set of nail heads are made of special steel, and the computer is precision machined.

8.Can be nailed single nail / double nail / /, reinforcing nail ( two ends are double nails in the middle part of a single nail) one-time completion, can be adapted to different customers' different requirements for nail types.

9.It takes only one minute to change the size of the carton and adjust the carton nail distance, which saves time and is convenient to operate.

10.The front feed unit automatically counts, and the paper feed table is equipped with a photoelectric sensor that automatically rises when feeding.

11.There is automatic counting function in the back section. The number of finished products can be sent to the end of the conveying machine in a set number (1-99), which is convenient for packing and binding.

12.The paper pad rubber wheel gap is electrically adjusted.

13.Order adjustment of the whole machine, can store 1000 orders.

14.The whole machine electrical isolation transformer protection function;

15.Automatic wire feeding system, 20KG flat wire, saving time.

16.Front and rear two-way baffle configuration, can order uncovered carton and small cardboard boxes, color boxes.

| FAQ |

1. Q: Are you a factory or trading company?

A: We are manufacturer. Cangzhou Gerun Machinery Co.,Ltd.

2. Q: Where is your company located? How can I visit there?

A: Our company is located in Dongguang County,Cangzhou City,Hebei Province. You can find us by searching in Google.We are near from Beijing/Tianjin city, only need 2/4 hours,We can arrange car to pick up from airport or hotel.

3. Q: Do you have any working machine for us to visit?

A: Yes,We can arrange visiting for you to any our customer factory in China.

4. Q: How is the warranty of the machine?

A: Our machines have ONE YEAR WARRANTY. And the engineers available for overseas service.

| Packing and Shipping |

Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation

and various types of weather conditions. A full set of maintenance and operation manuals is included.

|

| Our Services |

We deeply know that, excellent and efficient after-sales service is an indispensable part for clients to achieve due benefits. To offer most favourable and satisfactory service for wide clients, we hereby solemnly promise:

professional technicians will be assigned to client's site to give guidance in equipment installation and commissioning and hole training class for operators;we also offer charge-free training in our company for operators and maintenance personnel if requsted by clients.

The equipment will be delivered accompanied with detailed installation and operation manual and related information. Upon client's request,we can also offer plant layout design by free of charge.

| Details |

|  |

|  |