Hebei Jinguang Packing Machine CO.,LTD |

|

Verified Suppliers

|

|

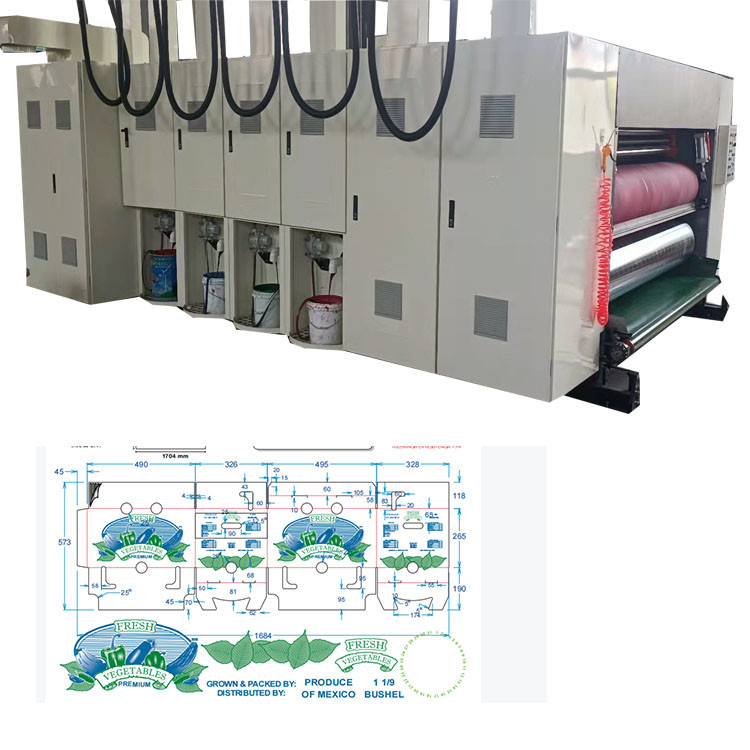

High Speed Pizza Box Making Machine Corrugated Box Printing Machine

※FEEDER UNIT

LEAD-EDGE FEEDING SYSTEM

Lead-edge suction feeding system, easy operation, high accuracy 7.5KW high pressure centrifugal fans, according to the cardboard warping degree of frequency control pressure, to ensure warp cardboard or thin cardboard high-speed accurate transmission.Left and right side baffle position electrically adjustable, screw-driven.and can remember by computer. Front baffle adjust the position of the upper and lower intervals synchronization by manual. Skip-feeding devices, could select skip-feeding according to needs. To ensure that large-scale cardboard can also be processed. Install 7” touch screen, could automatically display the production quantity, production speed, and set the production quantity and every operating. Slotting part is equipped with the interlock switch, to achieve the emergency stop, stop feeding or feeding.

MACHINE SEPARATION & COMBINATION

Button switches electrically control the separation and combination of machine, with automatic alarm device, continuously alarm while moving, to ensure safety of operators. Air pressure interlocks, lock securely, conveniently and accurately. Machine clutch drive shaft is equipped with overload protection device. Active self-locking function : if unit is not completely locking state, the host cannot start, to ensure the safety of machine and operator while host normal working conditions, the unit clutch function is automatically lock, to avoid machine misuse and personal injury.

DUST-REMOVAL SYSTEM

Adopt brush cleaning device, equipped with strong Negative pressure suction fan, clearing the dust, paper scrap or other waste, to improve printing quality.

FEEDING ROLLER: DOUBLE FEEDING ROLLER

Upper feeding roll adopts outer diameter φ175mm rubber roller, elastic buffer wear rubber (inside soft, outside hard), dynamic balance correction, to ensure smooth and accurate feeding. Lower feeding roller adopts embossed rollers, hard chrome-plated, wear and smooth. According to cardboard thickness, adopt worm gear box gap tuning, with locking device. Adjustment range 0-12mm.

※PRINTER UNIT

PRINTING ROLLER

With printing plate, outer diameter φ523mm. High quality steel production, surface grinded, hard chromium-plated. Static balance adjustment, stable operation, suitable for high speed running. Roller horizontal direction and circumferential direction with datum line, convenient for align plate. Fixed coil axis, suitable for standard hanging slats, realize rapid change plate. Electric 360° adjust printing roller, automatic digital display adjustment, remember store digital. Installed with foot switch to control plate roller reversing, convenient change plate. Auto-zero function, order memory. Printing roller plate-change and fix-plate function. Printing roll axial is adjusted left and right by manual, maximum movement left and right 10mm,auto-zero instruction.

PRESSING ROLLER

Adopt high quality seamless delicately processing, dynamic balance adjustment, stable operation.

Diameter φ175mm, surface grinded, hard chromium-plated.

Gear adopt backlash adjustment mechanism, adjustment none-affect gear enunciation, guarantee transmission accuracy.

Printing roller can be adjusted for a distance 0-12mm.

Pressing roller, feeding shaft can be adjusted by manual , and loose and tight the roller also by manual.

ANILOX ROLLER

Outer diameter φ216mm. Steel anilox roller.Steel anilox roller mesh:180-300 line

RUBBER ROLLER

Outer diameter φ200mm. Rubber roller adopts Guangdong Jingyang. Overrunning clutch and automatic idling device, to prevent the ink dried. Rubber roller drum type middle part higher, to ensure ink quality. Rapid spaced spinner self-locking device, ensures uniform ink. Ink distributing roller independent drive mechanism, ensure ink quality.

FEEDING ROLLER

Feeding roller diameterφ86mm, four wheels feeding.

Feeding roller gear adopts no-side-gap regulating mechanism, can adjust the interval of 12mm.

Hand adjustable rapid clearance adjustment self-locking device, fast, reliable.

INK SYSTEM

Pneumatic diaphragm pump, simple operation, convenient maintenance, supply stability. Circulating pneumatic ink. Screen for filtering impurities, guarantee printing quality.

PHASE ADJUST SYSTEM

Planetary gear structure. Digital computer 360 ° adjustment, both running and stopping state conditions. Printing phase adjustment of PLC computer display adjustment. After units separate, automatic reset system (eraser memory).

PHASE FIX SYSTEM

Pneumatic brake device, Unit separation and combination or phase adjustment, original point of transmission gear with constant

ZERO DEVICE

Auto-zero device, to ensure that the units have a uniform adjusted basis, reducing cardboard waste,edition memory function.

※SLOTTING UNIT(6 AXLES)

Single-axle double-knife slotter, use Internal tooth structure adjustment the height of box, So that oil does not easily contaminated cartons. Computer auto control cardboard size by Linear guideway. 6 shaft with rubber pre-creasing line, creasing line, slotter line. The first pressure line round, after pre-loading cardboard not easily crush. The above press round Urethane appearance package, will not damage the cardboard. The slotter knife stock use traverse mechanism, screw with linear guide, to move more flexible and precise. Slotting phase and box height, computer and electric digital control. Preload, creasing gap adjustment adopt computer and electric digital control. The slotter knife stock gap adjustment adopt self-locking structure. There's the elastic corner-cutting knife. Can cut three, five, cardboard without adjusted. Preload wheel, crease wheel, slot knife traverse position computer and electric digital control. The slotter knife adopt Anti-knife manner. Computer automatic arrange knife, can stockpile 999 memories.

※DIE CUTTING DEPARTMENT

1. Die roll

1)The roller diameter 360 standard template, surface grinding, hard coating.

2)Balance correction to increase the smoothness of operation.

3)The distance between the fixed screw holes of the knife mold is 100mm in the axial direction and 18 equally divided in the radial direction.

4)The use of crimping height 22.6mm.

5)The thickness of the wooden form work is 13mm.

2. Rubber pad roller (upper roller)

The outer diameter is ¢434.2mm, and the size of the rubber pad is ¢452.2mm

1)The rubber pad roller is made of high-quality steel, and the surface is ground.

2)Balance correction to increase the smoothness of operation. 3), the thickness of the foot pad is 8mm, the width is 252mm

4)The rubber pad roller is mechanically driven by the reversing transfer roller, and the horizontal movement is 40mm

5)Manually adjust the gap between the cutter and the die, the adjustment range is 0-12mm, and the accurate dial display is displayed.

3. Paper feeding upper and lower rollers

1)Upper roller: seamless tube with an outer diameter of φ86 mm, equipped with four paper feed wheels, and a quick adjustment device.

2)Lower roller: seamless steel pipe with outer diameter of φ155mm, surface ground, hard chrome plated.

3)Manual adjustment of the paper feed roller gap, the adjustment range is 0-11mm. Accurate dial display.

4. Phase adjustment device

1)Planetary gear structure.

2)The printing phase adopts the touch screen to control the electric digital 360 degree adjustment (the operation and stop can be adjusted).

3)Horizontal position, manually adjust the adjustable distance ±10mm.

4)The die-cutting plate roller adopts electric adjustment of the phase, the zeroing and plate adjustment speed is fast, and the plate adjustment accuracy is high.

| Wall board thickness | 60mm |

| Gear thickness | 60mm |

| Max Machine Speed (pcs/H) | 18000PCS/H |

| Max. Feeding Size (mm) | 900*2800MM |

| Max printing/working size (mm) | 900*2600MM |

| Min. Feeding Size (mm) | 300*650MM |

| Wall inner distance | 2000mm |

| Standard Plate Thickness (mm) | 3.94mm |

| Suit corrugated thickness | 2-12mm |

| Print precision (mm) | ±0.3 |

| Control | PLC touch screen |

| Rollers brand | JIZHOU |

| Electric equipment elements | SCHNEIDER |

| Switch | SCHNEIDER |

| Feeder unit | WITH DEDUSTING FUNCTION |