Wuxi Huadong Industrial Electrical Furnace Co.,Ltd. |

|

Verified Suppliers

|

|

Upcasting process oxygen free copper rod Annnual 2,000MT D17-30mm upward continuous casting production line

Main Technology Parameter For Copper Rod Up-casting Machine

| Annual 2000MT D17mm-30mm |

| Model: HDSYUCM-2000 |

| Yearly capacity:2000mt |

| Furnace structure : 300type two- body furnace ( 1.melting furnace 2. holding furnace) |

| Casting strands:4 |

| Casting rod diameter: 17mm— 30mm |

| casting speed: 0-1000mnVmin |

| annual working time:7920h |

| Liquidtracking precision:±2mm |

| Take-up coil standard; <p700mrrp<<p15CI0mnv<800mm |

| Copper melting velocity:260kg/h |

| Copper melting power consumption: <350kwh/lon |

| Take-up form: automatic adjust |

| Take-up plate driven approach: pushed by copper rod,manual adjusting |

| Material feeding methoctwhole piece of electrolytic copper cathode fed by electric hoist |

| Upward driven approach:dhven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet |

| Rod clamping method; manual clamping |

| Operation interface : date display,seoo motor controlled by touch screen |

| Total power:150KW AC three-phase 380V |

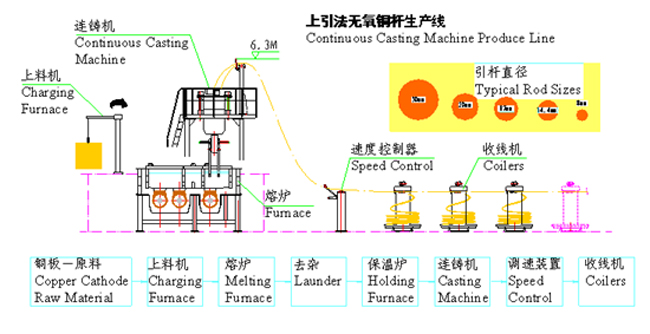

Equipment Composition

Electrolytic copper plate (cathode copper/99.9% copper scraps) -- charging device (can match) - furnace system (melting furnace -- transition warehouse - holding furnace) - continuous casting machine crystallization moulding) -- dragger - speed device - automatic winding machine - for sale or deep processing

Flow Chart

Electrolytic copper plate (99.9% copper scraps) is joined in the melting furnaces through the charging device (according to the user needs), (if the raw materials is not 1# red copper, our company can design and install the reverberatory furnace before melting furnaces to remove the copper impurity). The copper plate through W-type inductor into liquid, then flow smoothly from the transition storehouse to the holding furnace, and then is in the steady reduction process through the surface covered with charcoal, at last is crystallized swiftly to the cast copper rod by the crystallizerof the upcast plant by upward copper rod process at the same time, cast copper rod is upward casted intermittently through the two traction roller. The cast copper rod through the hauling machine, and the wheelframe, the speed adjusting gear, then to the automatic winding machine to wind copper rod.

No | Name | Quatity | Remarks |

| 1 | Upcasting melting and holding double conjoined combination furnace | 1set | |

Melting furnace coil | 1set | ||

Melting furnace water jacket | 1set | ||

Melting furnace steel core | 1set | ||

| Melting furnace melting channel | 1set | |

Holding furnace coil | 1set | ||

Holding furnace water jacket | 1set

| ||

Holding furnace steel core | 1set | ||

Holding furnace melting channel | 1set | ||

| 2 | Conjoined furnace refractory brick | 1set | |

Ramming material | 1set | ||

Al ore ceramic fiber board (thickness20mm) | 1set | ||

Temperature measuring thermocouple | 1set | ||

Thermocouple cases | 1set | ||

Copper liquid level tracking device | 1set | ||

Melting furnace and the holding furnace electric control cabinet | 1set | ||

| 3 | 10strands Servo control casting machine | 1set | |

Line oriented institutions | 1set | ||

PLC electric control system,Servo motor | 1set | Servo motor power:4.4KW Yaskawa,Japan PLC: Mitsubishi,Japan | |

Lifting platform | 1set | ||

Upcasting operatiion platform | 1set | ||

Servo operation counters | 1set | ||

| 4 | Upcasting limit frame | 1set | |

| 5 | Mould and furnace cooling water distribution system | 1set | |

Include:Temperature display, water temperature table, hydraulic pressure gauge, etc | |||

Bypass pipe, valves, | 1set | ||

| 6 | Frequency conversion double poles coiling machine | 5sets | Automatic,Frequency conversion |

| Including: coiling case, coiling trolley, rack, controller, Frequency conversion motor, reducer, etc | ||

| 7 | Continuous upcasting mould | 10set | |

| Indluce dummy bar and head | ||

Mould graphite dies | 30pcs | ||

Graphite cases and coat | 30pcs | ||

Quick connector | 15pcs | ||

Hose | 5coils | ||

| 8 | Installation material | 1set | |

Wires, cables, signal lines |

Wuxi East China Furnace Co.,Ltd

Whatsapp: 86 139 2112 5611

joey@wxhddl.cn