Henan Coal Science Research Institute Keming Mechanical and Electrical Equipment Co. , Ltd. |

|

Verified Suppliers

|

|

Items | Unit | KFP-65-20A Foam Concrete Pump |

Rated voltage | V | 380 |

Main motor | KW | 7.5 |

Output | m3/h | 12 |

Vertical delivery dist. | m | 20 |

Horizontal delivery dist. | m | 60 |

Particle size | mm | 6 |

Output pressure | Mpa | 1.5 |

Dimensions (L*W*H) | mm | 1800*1200*1500 |

Main machine weight | Kg | 1300 |

Mixer dimensions | mm | 1600*800*1300 |

Mixer weight | Kg | 150 |

1. Take cement and coal ash as raw material to make foam concrete.

2. Insulating layer, bedding course, floor heating, filling projects of foam concrete roofing.

3. Other products of foam concrete.

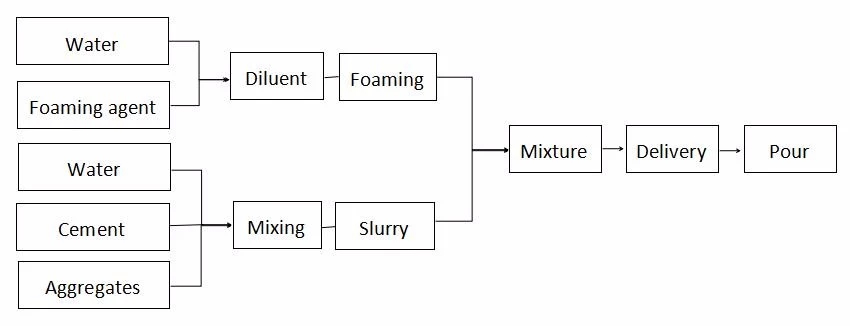

1. KFP series Concrete Foaming Machine combines feeding machine, water adding device, mixing system, foaming system, delivery system into one machine.

2. The machine shell is made of high strength and precious steel plate and painted at high temperature of 280℃, ensuring long service life.

3. Small size,light weight, convenient transport and loading.

4. Automatic mixing of cement slurry, automatic foaming of foaming agent, automatic delivery of foaming concrete.

5. Frequency converter control of main pump, and digital display of delivery output.

6. Even and steady output of cement slurry, uniform density of foam concrete, stable quality.

7. Delivery system adopts the most advanced hose pumping system, with simple operation, low fault rate, less wearable parts, convenient maintenance,and low cost.

8. The machine saves production costs and improves economical returns.Compared with similar products, the machine can save 50~100kg cement per cubic meter product.

9. Professional technician team, excellent after-sales service, perfect technical guide.