Dhh Compressor Jiangsu Co., Ltd |

|

Verified Suppliers

|

|

15kW Combined Rotary Screw Air compressor Integrated Fiber Cutting Air Compressors

Technical Parameters

| Model | CPBZY15 |

| Type | Fixed air-cooled twin-screw air compressor |

| Dimensions | 1882×790×1732mm |

| Installation method | Fixed installation without foundation |

| Rated displacement | 1.51m3/min |

| Rated exhaust pressure | 1.58Mpa |

| Exhaust oil content | ≤0.003 ppm |

| Exhaust pressure dew point | 2~10°C |

| Compression stages | Single-stage |

| Transfer method | belt |

| Compression oil consumption | 8L |

| Cooling method | Air cooling |

| Cooling air volume | 3500 m3/h |

| Ambient temperature | 0 ~ 45°C |

| Noise | ≤65 dB |

| Weight | 560kg |

Notes:1. A represents air-cooling type,W represents water-cooling

type;

2. Working Environment temperature: -5ºC~45ºC;

3. Discharge temperature is less than ambient temperature

+10ºC~15ºC;

4. Drive Mode: belt driven;

5. Startup Mode: direct start under 11kw, and above 11kw;

6. Work Power: 380V / 50HZ, 460V / 230V / 6KV and 10KV voltages can

be made for customers;

7. F.A.D volume flow test is according to ASMC PTC9 or ISO1217

standard (GB/T3853)

Product advantages

1. High stability

Imported screw main machine ensures high efficiency, high stability, smoother cutting and cutting surface.

2. High-efficiency motor

Dustproof and waterproof motor, the protection level reaches IP54, which meets the environment with more dust and smoke, dust and moisture in the air are not easy to enter the motor, and maintain long-term trouble-free operation.

3. One-piece does not need to be installed

Easy to use and transport, easy to operate.

4. Multi-stage high efficiency filter

The multi-stage high-efficiency US original Donaldson filter, with a filtration accuracy of 2um, ensures that the air inhaled by the host is pure and free of impurities, and ensures the host's trouble-free operation.

5. Low noise

Shock-absorbing frame, thickened sheet metal thickness, and thickened shock-absorbing pads to minimize noise.

6. Thermostatic control

Minimize the water content inside the system to ensure long life and high efficiency of the air compressor.

7. 500L large capacity storage tank

500 liter bulk tank for air storage and buffering. The air supply is more stable, preventing frequent loading and unloading of the compressor. The precipitation of compressed air in the tank is also more conducive to sewage and water removal.

DuriAuxiliary gas for Fiber Laser Cutting, did you get the right

one?

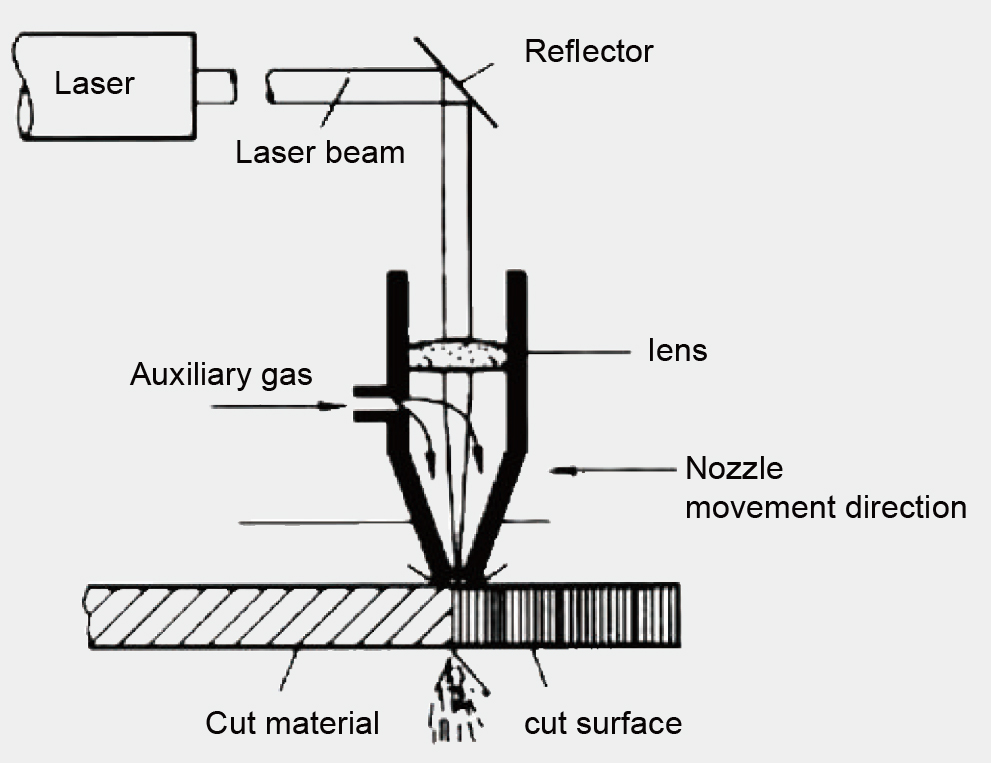

The schematic diagram of laser cutting is shown in the following.

During the process, auxiliary gas is necessary to blow off the

slag/dross in the kerf and cool down the cutting surface, also it

protects lens and nozzle of laser. Basically there are 3 kinds of

gas: Oxygen, Nitrogen and Air, any of them affects directly to the

cutting performance, speed, thickness etc. So we really need to

think better before action.

1.OxygenOxygen is commonly used to cut thick carbon steel because

the chemical reaction between iron element and oxygen helps the

metal absorb heat and promotes it melt, which can greatly improve

the cutting efficiency.

However, oxygen will cause a marked oxide film on the cut surface

and it will have a quenching effect around, increases the hardness

which impact on subsequent processing. It also turns kerf to black

or dark yellow.

2. Nitrogen

Nitrogen will form around the molten metal as protective atmosphere

while it's assisting the cut, prevent oxidation of the

material, avoid the formation of oxide film. However, the cutting

speed is not as fast as oxygen, and the nitrogen consumption of the

nitrogen is large which means the cost will be higher.

3. Air

Air, as it's the most economic medium because it's much easier to

obtain than oxygen and nitrogen, nobody can charge you for air!

Every one knows the air contains about 20% oxygen and about 78%

nitrogen, so it can make up for both shortage and cutting speed is

slower than oxygen but faster than nitrogen. Since the oxygen is

involved, the kerf turns a little bit yellow. It's the most

economic option for you as long as you are okay with the color

change.

Generally compressed air can be used for cutting sheet-metal parts,

aluminum sheet, nonmetal and galvanized sheet etc., air assist

can certainly reduce the oxide film and absolutely save your cost,

therefore, air assist is more and more equipped in fiber laser cut

industry.

Compressed air can be obtained easily with an air compressor, but

not any air compressor can be equipped for Fiber Laser Cutter as

the Air itself is not clean, especially after compressing, there

are plenty of water, oil and particles and any of them sprayed on

the lens, the transmission of laser beam will be seriously affected

and focus scattered, resulting bad cutting effect such as bottom

burrs or rough kerf, even obsolescence.

Situation could be much worse if it is high-power fiber laser, even

a tiny particle or a little spray will very possibly burn your

entire lens cone.

In order to make the most economic (Air assist) way workable,

ensure cutting quality and avoid any damage for your fiber laser,

the compressed air must be pure and constant, 100% meet ISO

8573-1-2010 standard.

Dehaha 4-in-one (Compressor + receiver tank+ dryer + filters) high

pressure air compressor is special compressor for Fiber Laser

Cutting industry, custom built to provide filtered, dried,

continuous reliable supply of high pressure compressed air at

2~10ºCdew point to assist laser cutting. Produce your own assist

air at a fraction of the cost of cylinder.

Dehaha Compressor was founded in 1996 with over 150 skilled employees and more than 25 R&D engineersteams ’ . We focus on the research & develop,manufacture and energy-saving solutions of screw air compressor to create value for customers and society.In 2018 our total sales volume approached 15 million US dollars.By over 23 years enhanced experiences of designing,producing and marketing,today our valued customers are over 130 countries.

Germany Standard and 13 years exporting experience help us won more

than 50 loyal overseas agents.

Dehaha’s primary businesses focus in following key areas:

Oil-injected rotary screw compressors

Portable screw air compressors

Oil free air compressors

High pressure air compressors

Air treatment equipment

1.24/7 after sales service support in different languages.

2.Follow up the feedback of products in 2 months

interval by email or call.

3.Guidance of installation and commissioning on site can be

provided by factory-trained technicians or local Authorized Service

Center.

4.Technical training for customers in DEHAHA air

compressor factory or working site.

5.Plenty of original spare parts with proven quality are

all available from our central stocks in Shanghai and all

distributors’depots.

6.All kinds of technical documents in different languages.

Q1:Are you factory or trading company?

A1: We are factory.

Q2:Where is your factory located? How can I visit there?

A2: Our factory is located in Qidong City, Jiangsu Province, China.

We can pick up you from Shanghai, it's about 1 hour from Shanghai

Pudong Airport to our factory. Warmly welcome to visit us!

Q3: Will you provide some spare parts of the machines?

A3: Yes, of course.

Q4: Warranty terms of your machine?

A4: Two years warranty for Air End, one year for spare part.

Q5: How long will you take to arrange production?

A5:380V 50HZ we can delivery the goods within 14 days. Other

electricity or other color we will delivery within 22 days.

Q6:How does your factory do regarding quality control?

A6:Quality is everything. we always attach great importance to

quality controlling from the very beginning to the very end. Our

factory has gained ISO9001 authentication and CE certificate.

Q7: Can you accept OEM orders?

A7: Yes, with professional design team, OEM orders are highly

welcome.