Shenyang Jingcheng Electromechanical Equipment Co., Ltd. Bazhou branch |

|

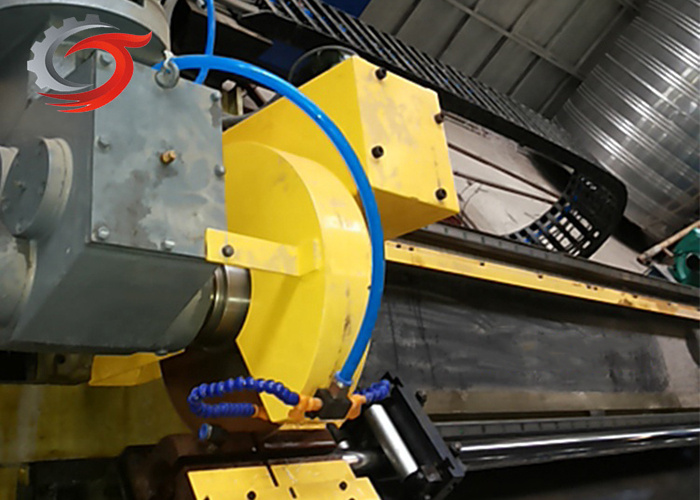

Fly Cold Saw Customized round pipe cutting saw for large size pipe making machines

Introduction

The oversized rack-and-pinion drive system ensures vibration-free acceleration during acceleration, so that the correct synchronizing speed can be reached quickly. The blades are heat treated to achieve a surface hardness that is immune to vibration and resonance phenomena. The machine adopts a fully automatic control system with a very user-friendly HMI interface.

Cutting range | Square tube:MAX90×90mm | thick:0.5~4.0mm |

| Rectangular tube:MAX 50×90mm | thick:0.5~4.0mm | |

| Cutting length | 1500-99999mm | |

| Cutting burr height | Max:0.25mm; | |

| Power supply | AC380V,3PH,50HZ | |

| Mechanical length | 5420*1480*1380mm(as per final drawing) | |

Motor list | Drive:18.5KW | PHASE servo motor |

| feed: 3.3KW | PHASE servo motor | |

| saw: 22KW | PHASE servo motor | |

| Clamp block model | tape shape to avoid scratching the steel pipe | |

| Cable protection | Drag chain | |

| Equipment document | User’s manual & electrical diagram | |

Features

1. Automatic control (also manual control)

2. Smooth and flat tube ends

3. Length tolerance: ±0.5mm

4. Friendly man-machine interface

5. Siemens servo system

6. Stable and reliable

7. Quiet, higher safety

8. Large LCD touch screen.

9. High-speed and high-precision cutting.

10. Excellent cutting edge, no burr, saving product cost

Our service

1. Professional pre-sales consultation and after-sales service to

help you find the best solution

2. Discuss technical details with our professional engineers

3. Strictly control the quality and production plan of the cold

flying saw. You will be kept informed of any progress

4. Check the cold flying saw before shipment

5. After the warranty period, spare parts are provided at cost

6. Professional engineers help you increase production, reduce

waste and reduce costs

7. Control the production progress and quality of the machine, and

provide you with detailed information in time