Shandong Decho Building Materials Technology Co., Ltd |

|

Verified Suppliers

|

|

AZ120 AFP Galvalume Steel Tile A792M CS-B Roof Tiles Corrugated Sheet Panels

AZ120 GL 55% Aluzinc Steel Coil

Introduction:

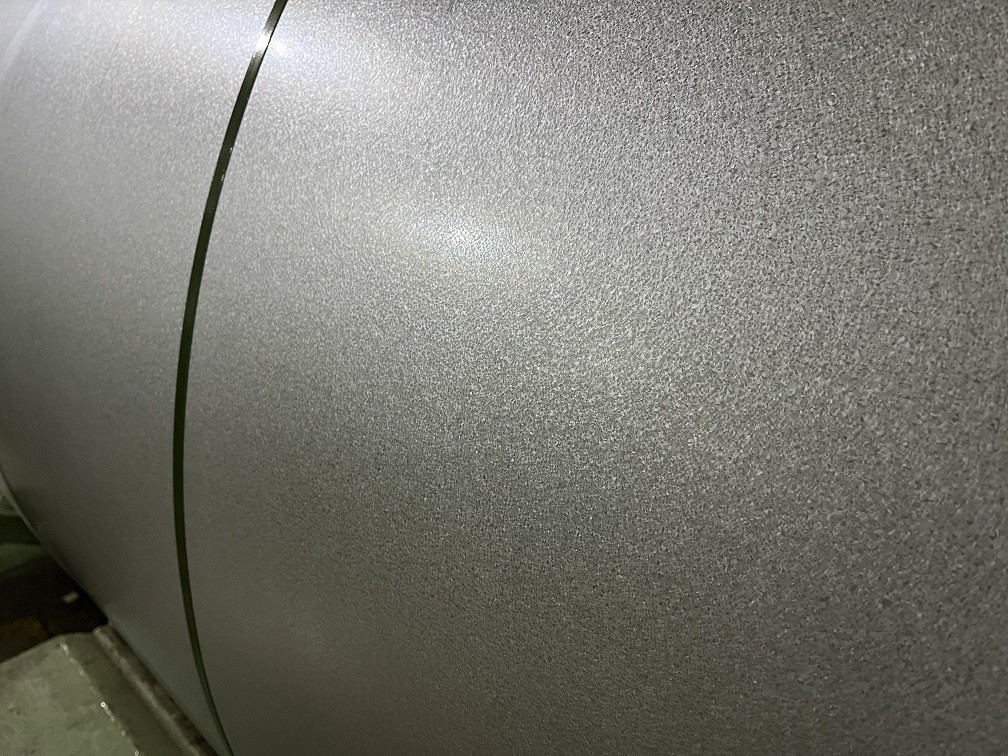

Hot-dip aluminium-zinc coated steel plate is a pre-coated steel plate obtained by hot-dip plating a layer of Al-Zn coating on both sides of a cold rolled steel plate of various strengths and thicknesses as a substrate, with a mass percentage of 55% Al (aluminium), 43.5% Zn (zinc) and 1.5% Si (silicon) in the composition of the plated layer, which combines the physical protection of Al and high durability as well as the electrochemical protection of Zn, and has the strength and plasticity of the base steel, and the corrosion resistance of the coating. The material has the strength and plasticity of substrate steel and the corrosion resistance of plating, which protects the metal substrate from internal corrosion. In addition, the surface has a highly decorative bright silver grey colour and regular patterns with a sense of embossment.

Aluminium-zinc-steel plated light steel has quite a few excellent characteristics: Strong corrosion resistance, 3 times that of pure galvanising; beautiful zinc flowers on the surface, can be used as building roof exterior panels. Abbreviation AZ150, aluminium-zinc-steel plates keel for a long time without colour change on the bare surface, such as chemical corrosion, the surface of the physical reaction occurs, the formation of aluminium protective film on the surface of the keel, so that the outside world of chemical substances and the keel separated from the separation of the keel, to protect the keel of the main body of the material, to prevent rusting.

G550 550Mpa 2.06X105 N/mm 2 7.85g/cm 3 1.2×10-5℃

The commonly used mechanical properties and physical parameters of G550 aluminium zinc plating are as follows:

Name Yield strength Modulus of elasticity Volume weight Coefficient of thermal expansion

G550 550Mpa 2.06X105 N/mm 2 7.85g/cm 3 1.2×10-5°C

Coating content classification

| SURFACE TREATMENT | DESCRIPTION OF USE |

| CHROMATE PASSIVATION(C) | Surface treatment for high-strength steel plates after hot-dip plating to reduce white rust during transport and storage |

| Chrome-free passivation(C5) | Surface treatments that require limiting the amount of hexavalent chromium, etc. in passivation solutions that are harmful to the environment and humans |

| Anti-finger print(N) | Surface treatment after the passivation process, which acts as a lubricant during processing, prevents fingerprints from staining during operation, and prevents premature blackening of the surface during use. |

| Chrome-free and fingerprint resistant(N5) | Surface treatment after the passivation process, in the process of lubrication, to prevent the operation of the fingerprint staining, to prevent the use of the surface of the process of premature blackening, and at the same time, the requirement to limit the fingerprint-resistant film harmful to the environment and human body, such as hexavalent chromium content |

| Oiled(O) | Surface treatment added after the passivation process to further reduce rusting during long-distance transport and long-term storage |

Characteristics:

Advantages of Galvalume Steel which Compared with Galvanized

Which is more scratch-resistant and durable, light steel keel galvanised or aluminium zinc plated?

The difference between galvanised and aluminium zinc plating

Lightweight steel coatings are divided into two types: galvanised and aluminium zinc plated:

Galvanised: the amount of galvanised light steel plating and can be determined according to its different use of the environment and function of the amount of galvanisation required; in order to strengthen the corrosion resistance, can be controlled in accordance with the different requirements of the thickness of the galvanised layer can be in the 120g/m2 - 275g/m2.

Galvanised steel sheet Z275 - i.e. galvanised steel sheet, Z275: zinc layer weight designation, indicating the weight of zinc contained in the steel sheet on both sides 275g/m2.

Galvanised Physical Changes: Galvanised is exposed all year round to react with oxygen in the air and the surface will blacken.

Aluminium zinc plating: aluminium zinc plated light steel has a number of excellent characteristics: strong corrosion resistance, 3 times that of pure galvanised; beautiful zinc flowers on the surface, which can be used as a building exterior panels. Abbreviation AZ150, aluminium-zinc-plated keel for a long time without colour change on the bare surface, such as chemical corrosion, the surface of the physical reaction occurs, the formation of aluminium protective film on the surface of the keel, so that the outside world of chemical substances and the keel separated from the separation of the keel, to protect the keel of the main body of the material, to prevent rusting.

Corrosion resistance is mainly because of aluminium, the protective function of aluminium. When zinc is abraded, aluminium forms a dense layer of aluminium oxide, preventing further corrosion of the corrosion-resistant material inside.

Aluminium-zinc plated alloy steel coils have been subjected to outdoor exposure tests for more than 20 years in a variety of different atmospheric environments, confirming that the protective function of aluminium-zinc plated steel sheets with cut edges is much better than that of galvanised steel sheets.

Heat reflectivity

Aluminium-zinc-plated mild steel has a high thermal reflectivity, twice that of galvanised mild steel, and is often used as a thermal insulator.

1) Standard: ASTM A792M, AS1397, EN10346/ EN10143 all according to the customer's request

2) Grade: SGCC, CS-Type B, Grade 350, G550, Grade 50, Grade 80,

SS550GD, all according to the customer's request

3) Capacity: about 20000 tons per month

4) Thickness: from 0.13mm to 2mm, all available

5) Width: from 600mm to 1250mm, regular

size:750-762mm,900-914mm,1000mm,1200mm,1219-1250mm all available

6) Coil ID: 508mm

7) Coil weight: from 2-10MT, according to the customer's request

8) Zinc coating weight: AZ30~AZ165g/m2

9) Spangle: regular spangle,big spangle, small spangle

10) Surface treatment: Anti-finger print (Green, Blue, Golden, No

color) Chemical passivating, oils, passivating oils,skin

passed

11) Edge: mill edge, cut edge

12) Min trial order 25 ton each thickness

Application:

Detailed Parameters:

| SURFACE TREATMENT | DESCRIPTION OF USE |

| CHROMATE PASSIVATION(C) | Surface treatment for high-strength steel plates after hot-dip plating to reduce white rust during transport and storage |

| Chrome-free passivation(C5) | Surface treatments that require limiting the amount of hexavalent chromium, etc. in passivation solutions that are harmful to the environment and humans |

| Anti-finger print(N) | Surface treatment after the passivation process, which acts as a lubricant during processing, prevents fingerprints from staining during operation, and prevents premature blackening of the surface during use. |

| Chrome-free and fingerprint resistant(N5) | Surface treatment after the passivation process, in the process of lubrication, to prevent the operation of the fingerprint staining, to prevent the use of the surface of the process of premature blackening, and at the same time, the requirement to limit the fingerprint-resistant film harmful to the environment and human body, such as hexavalent chromium content |

| Oiled(O) | Surface treatment added after the passivation process to further reduce rusting during long-distance transport and long-term storage |

| Usage | Steel Grade | Yield Strength(MPa) | Tensile Strength(MPa) | Elongation at break A80mm % ≥ |

| Generally used | DC51D+AZ | 190~360 | 270~500 | 22 |

| stamping | DC52D+AZ | 140~300 | 270~420 | 26 |

| deep drawing | DC53D+AZ | 140~260 | 270~380 | 30 |

| extra-deep washout | DC54D+AZ | 120~220 | 260~350 | 36 |

| Usage | Steel Grade | Yield Strength(MPa) ≥ | Tensile Strength(MPa) ≥ | Elongation at Brake A80mm % ≥ | Elongation at Break A50mm % ≥ |

| Structural usage | S250GD+AZ | 250 | 330 | 19 | / |

| S300GD+AZ | 300 | 380 | 18 | / | |

| S350GD+AZ | 350 | 420 | 16 | / | |

| S450GD+AZ | 450 | 480 | 15 | / | |

| S550GD+AZ | 550 | 550 | / | 2 |

| Environment | Zinc Weight/ G/sqm |

| indoor environment | AZ70 or AZ100 |

| Suburban environment | AZ150 or AZ100 + painting |

| Urban or industrial areas | AZ150+ pre painted paint coating |

| Coastal Areas | AZ180+ thick paint coating |

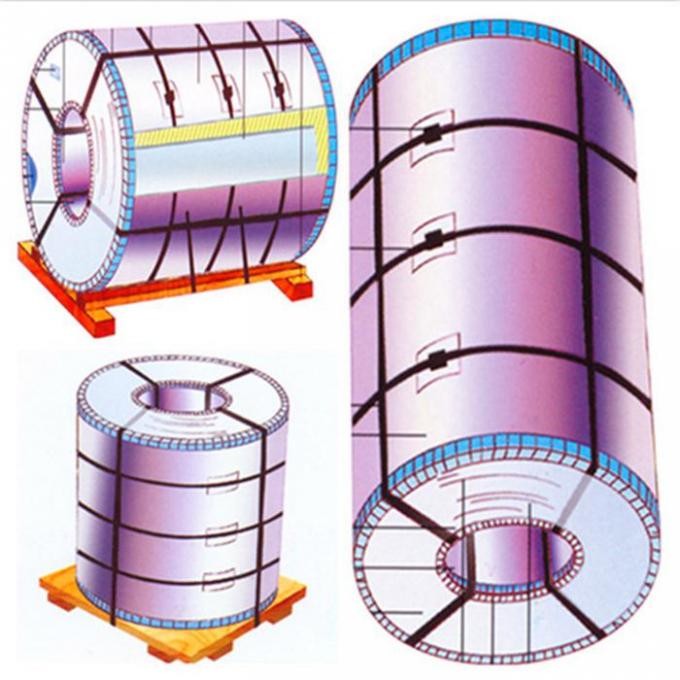

Export Package

Why Us:

DECHO building colour steel plate can meet the need to use colour steel plate as raw material for building. Decho Building Materials colour steel plate is mainly processed into, for example, colour steel corrugated board or colour steel composite sandwich board after our colour steel plate is widely used in the construction of airports, freezers, steel plants, warehouses, and other industrial buildings and commercial buildings, such as the roof of the colour steel tiles, colour steel plate sandwich walls and doors.

Reasons for choosing Decho Building Materials new material:

Welcome to enquire.