China Coal Rainbow Machinery Equipment Co., Ltd. |

5-10TPH Semi-automatic Tile Adhesive Machine

Introduction:

Semi-automatic Tile Adhesive Machine mainly produces ordinary premixed mortar and special mortar. The whole production line includes Wet Sand Drying System, Screening System, Storage System, Weighing System, Mixing System, Bulk&Packing System, Dedusting System, etc.

Advantage:

Dry Mortar Production Line Main Equipment:

Ploughshare Mixer&Agravic Mixer

Three-cylinder Rotary Dryer&Dryer Dust Collector

Bucket Elevator&Screw Conveyor

Probability Screen&Packing Machine

| Parameter Name | Production Line Model and Parameter | ||||

| Name | Unit | ZMZS5000 | ZMZS4500 | ZMZS3000 | ZMZS2000 |

| Design Capacity | TPH | 80-85 | 55-60 | 35-40 | 20-25 |

| Annual Capacity (300d/y*16h/d) | TPY | 400,000 | 300,000 | 200,000 | 100,000 |

| Mixer Model | / | ZMDH5000 | ZMDH4500 | ZMDH3000 | ZMDH2000 |

| Mixer Volume | m³ | 5 | 4.5 | 3 | 2 |

| Load Factor | / | 70% | 70% | 70% | 70% |

| Mixer Power | KW | 90 | 75 | 55 | 45 |

| Dryer Model | / | ZMST3275 | ZMST3270 | ZMST3265 | ZMST2560 |

| Dryer Capacity | TPH | 80-85 | 55-60 | 35-40 | 20-25 |

| Dryer Power | KW | 4*11 | 4*7.5 | 4*7.5 | 2*11 |

| Powder Silo Volume (Cement,Fly Ash etc) | m³ | 3*120 | 3*80 | 3*80 | 3*50 |

| Sand Silo Volume | m³ | 3*140 | 3*140 | 3*140 | 3*80 |

| Additive Silo Volume | m³ | 2*1.5 | 2*1.5 | 2*1.5 | 2*1.5 |

| Sand Weighing Volume | m³ | 3 | 2 | 1.2 | 0.6 |

| Sand Weighing Accuracy | % | ≤±1.5 | ≤±1.5 | ≤±1.5 | ≤±1.5 |

| Powder Weighing Volume | m³ | 1.5 | 1 | 0.8 | 0.4 |

| Powder Weighing Accuracy | % | ≤±1 | ≤±1 | ≤±1 | ≤±1 |

Production Line Overall Dimension | m | 22*15*28 | 22*15*28 | 22*15*28 | 22*15*28 |

| Total Installed Power | KW | 420 | 380 | 350 | 320 |

Dry Mix Mortar Raw Materials:

Application Range:

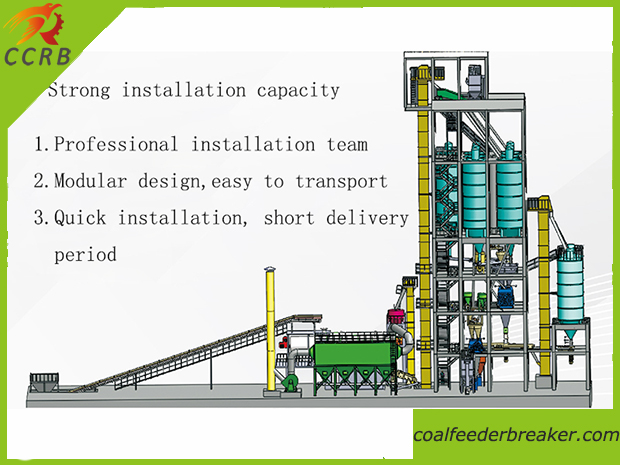

Installation and Delivery:

Strict site three-level quality inspection system

Training System:

Provide professional staff training for customers

Company Information: