Hongkong Winhoo Precision Co., Ltd |

|

Titanium Aerospace Machined Parts Metric Aircraft Hardware Wear Resistant

Titanium Aerospace parts precision CNC machining Wire cutting defense markets parts

Navigation Part Precision machined parts

Material: Titanium TC4 Surface:polishing Concentricity:0.01mm

Rugosity:Ra0.2 olerance:0.01mm Diameter:Ø65mm

Verticality:0.03mm L*W*H(mm)=65mm*65mm*20mm

Metal:Titanium

TC4,TA9,TW340,AL2A12,AL6082,AL7075,SUS303,SUS304,30CrMn.

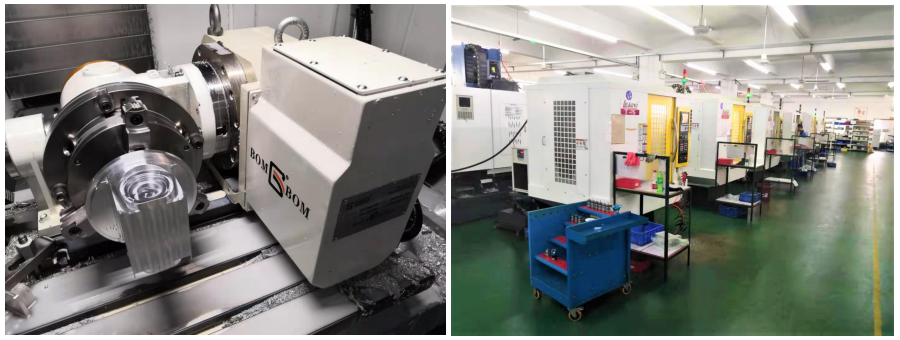

Machine:CNC machinging center,CNC lathe,Wire cutting macine,Milling

machine,Grinding machine,EDM.

Surface treatment:sand blast,,anodizing,Engraving,Gold plating.

Purpose:unmanned aerial vehicle,drone, UAV

Aerospace,Defense,Aircraft,guided missile,Submarine,

Navigation

Main Products Display

Why are you choose us ?

| Fully reinforced | 10 Years of Practical Experience | High Quality, Best Cost |

| Professional production equipment more than 60 sets, imported CNC, Japan's Jinshang turning and milling machine, all cutting processing completed at one time. Annual production of precision spare parts more than 10 million pieces, annual sales of more than 50 million RMB. | We have a professional and experienced team, with more than 10 years of mechanical processing experience. For nearly 1000 enterprises, factories customize hundreds of thousands of products. Focus on more professional, we intentionally do a good job in every product, in return for customer trust in us. | High precision, high speed, high-end equipment, In the long-term production process, we have established a perfect quality management system, so that the quality of products can be controlled steadily in the manufacturing process. To strive for the highest level of product quality beyond customer expectations. |

| From trial production to mass production, 1PCS can also be ordered. | Surface treatment, heat treatment | Compliance with ROHS Directives |

| From trial production to batch production, the quantity is unlimited. For the sample for trial production and test, 1PCS can be ordered. Batch production of 20-30,000 also has sufficient capacity to meet production, on time delivery. | We not only provide precise mechanical processing, but also carry out various kinds of surface treatment and heat treatment according to the needs of customers. Provide one-stop service. | All kinds of raw materials and surface treatment fluids used meet the relevant requirements of ROHS REACH Directive, and can provide SGS and MSDS harmful substances detection report |

| Fastest response | Safe and Fast Logistics | Careful and meticulous service. |

| The fastest response, rapid delivery, strive for every minute and every second for customers. Quote quickly for 24 hours. Sample supply: Sample delivery period is 3-10 days. 365 days of production throughout the year. | All products are cleaned and rust-proof, and carefully packaged with cushioning materials and plastic suction boxes to ensure that nothing is wrong. Overseas logistics experience, FOB, CIF, DAP and other trade terms and air, sea, express and other logistics methods can be corresponding. | No matter the quantity of production, from trial production to batch production, we will take it seriously and do our best. Provide one-stop all-round service for mechanical processing, heat treatment, surface treatment and assembly. |

FAQ:

Q1: Could you give me your best price?

A1: Of course, we are a professional manufacturer, so we could supply the best price without many middlemen.

Q2: If my quantity is very small, could you do my products?

A2: Yes, we can. Do not worry about the quantity. We will provide different production ways based on your quantity.

Q3: How long would the delivery time?

A3: It is based on all of your requirements about the products.

Q4: How can you guarantee the quality?

A4: We have a powerful QC team to control the quality in every production process. We believe the best

quality is our enterprise life. That’s why we have lots of big group companies.

Q5: I want to buy your products, how can I make the payment?

A5: We can accept the T/T and western union.

Q6: What are your mainly customers around the world?

A6: Our mainly customers are from North American, Western Europe and Japan.

Q7: I didn’t find the products I want, can you OEM for me?

A7: Yes, we are a professional OEM and ODM manufacturer with 10 years’ experiences. We can OEM and

ODM the products which you need. Our aim is “You have the idea, we turn it into products”

If you have any further questions, please just feel free to contact me directly. I will try my best to service you

and your company. I hope we will be a good cooperation in the futuue.

Quality policy

Our measuring equipment:

CMM

Projector

Concentricity measurement

Hardness tester

Thread Ring Gauges

Pin Gauges

Micrometer

Vernier Caliper

Roughness machine

Our precision machined components are implemented of ISO9001:2015,combined with our in-house quality

control system and these measuring equipments,ensure problem-free products.

Marketr and Service

We Are Committed To Fulfilling Your Needs,We Are Proud Of Your Every Success