Xiamen DingZhu Intelligent Equipment Co.,Ltd |

|

Verified Suppliers

|

|

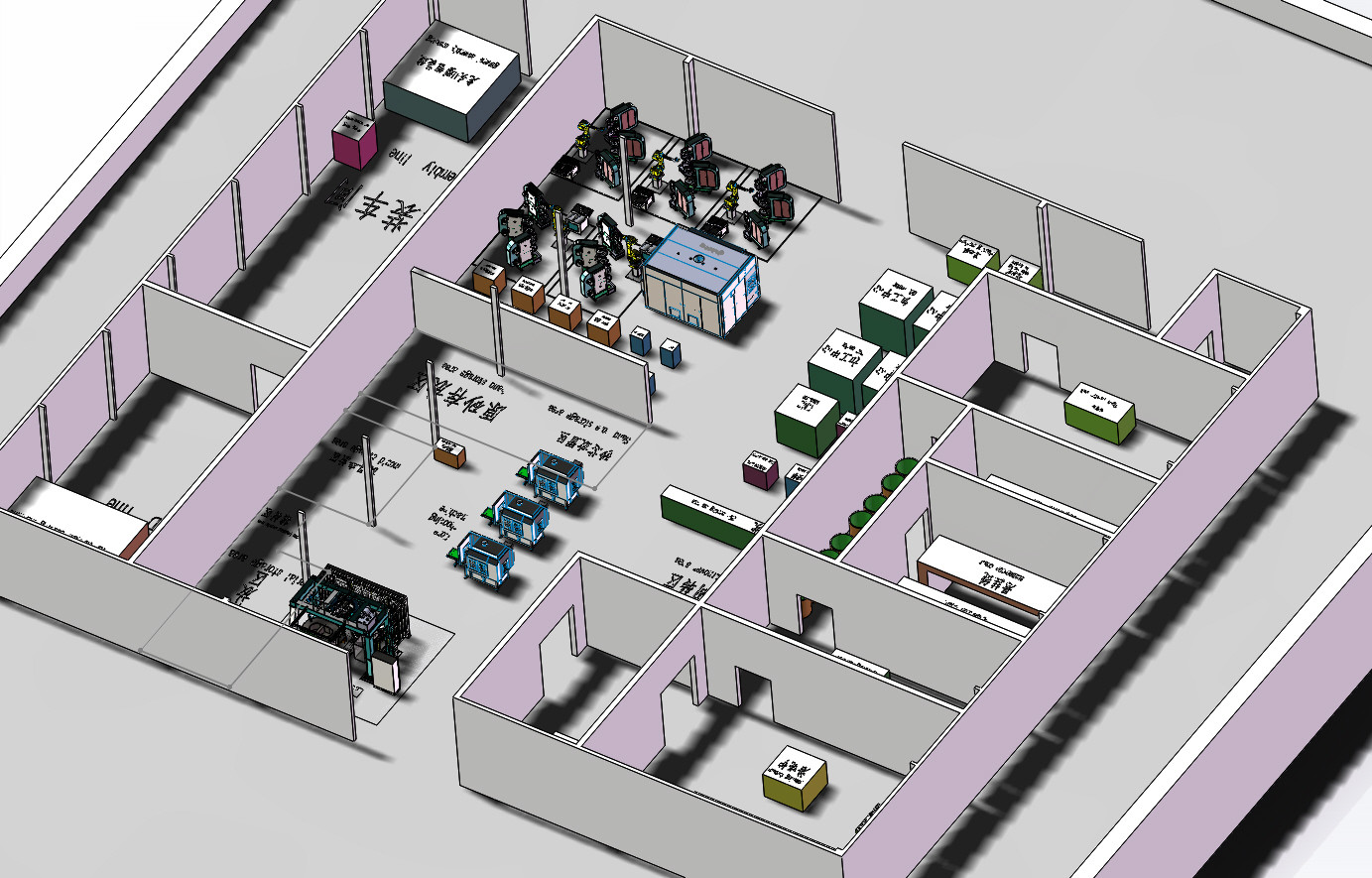

Robotized Line For Grinding And Polishing Faucets And Brass Parts.

Our know-how has been acquired day after day Our team has more than 20 years of practical experience in developing automation equipment and producing faucets. Our enginners used to work in Lota group, The website:http://www.xmlota.com/ ,Lota group is one of the world’s largest and most respected manufacturers of high quality faucets.They are main position is R&D intelligent equipment for faucet production line,including :Sand mixer,Casting machine ,CNC machining ,Grinding robot and Polishing machine. Growing with our customers through a constant exchange of knowledge and experience, through after-sales service, through the evolution of DZ’s Engineering products and innovative solutions.

The production phase Our main characteristic is to fully understand the production process of manufacturing taps and fittings for sanitary-ware and products in brass and bronze. From the foundry and forging, to machining,ginding ,polishing and the automatic assembly, up to the testing and quality inspection lines, we are able to offer solutions for the whole production process, as well as for the individual technological areas, with targeted intervention work.

High added-value integrated projects Whether it is the individual machine or the complete turnkey plant, you can contact us for any need, whether it is of a production, the equipment selection ,management , plant layout ,production process technical support. Our plants are characterised by a detailed process analysis, as well as a rationalisation of the resources to be used. The purpose is to give the maximum yield with the right amount of investment. The plants that we design and offer cover the whole production range. For example…

Foundry and Forging Machines and plants for gravity and low-pressure casting. Complete drop-forging plants. Induction and gas furnaces, sand mixers, core-moulding machines, automated cast-cutting centres.

Transfer and Mechanical Machining Transfer machines, automatic lathes, pipe bending and shaping machines, machining centres.

Grinding and Polishing Honing systems. Automatic and semi-automatic systems for surface cleaning.

Surface treatment Chrome and nickel-plating systems. Painting systems.

Assembly Semi-automatic and fully automatic assembly lines. Assembly and testing zones. Labelling lines.

Special Plants Robotised zones. Automated loading and unloading lines. Raw material feeding lines. Fume suction plants, Environmental protection dust removing equipment,Industrial washing and water treatment plants.