Xi an Hi-Precision Machinery Co., Ltd. |

|

Verified Suppliers

|

|

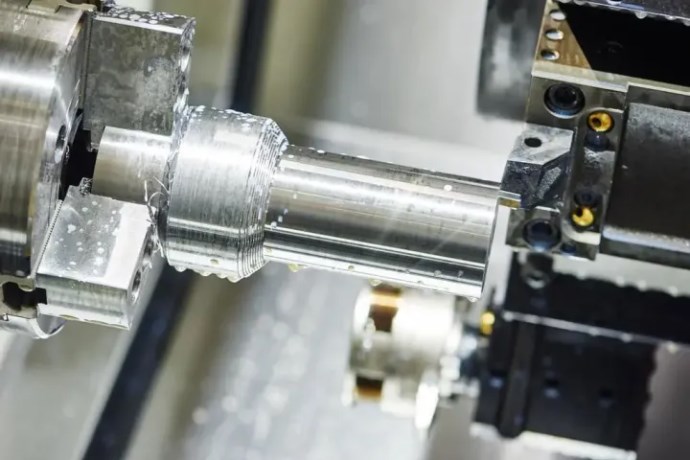

Model name: Long shaft

Application: Industrial machine equipment

Material grade: steel, stainless steel, aluminum

Surface Finished: machined natural color, blacken, anodizing

Process: CNC Turning

Tolerance:±0.01~0.02m

Size and weight: custom according to customer’s requirements.

| Advantage | Competitive factory price and superior quality Professional and experienced technology team Focus in high precision CNC machining Consistently meet the tight tolerances required Low MOQ and free sample Short lead time (20 working days) ISO9001:2008 certification and materials accord with Rohs standard Excellent after sale service and good warranty |

| Our service | Electronic and communication, Aerospace, Optical instrument, Medical and pharmaceutical, Oil, gas and petroleum, Railway, electric tool, car, robot, hydraulic equipment |

| Equipments | CNC Machining Center, CNC Lathes, CNC Milling Machines, wire cutting, laser cutting Stamping machines , Assembly lines, Whole set of measurement tools |

| Precision Processing | CNC machining, CNC milling and turning, laser cutting, drilling, grinding, bending, stamping, welding and so on |

| Drawing format | JPEG,PDF,DWG,DXF,IGS,STEP.CAD or according to your sample |

| Material | Stainless Steel, Brass, Aluminum, Steel, Carbon Steel, Titanium , plastic. Or other Exotic Alloys |

| Surface Finish | Anodize; Blacken, polishing, plating, sand blasting |

| Tolerance | +/- 0.002--0.5mm / can also be customized. |

| Inspection | 100% inspection before shipping |

| Payment Terms | 30%T/T in advance, the balance before delivery; Western Union is acceptable, the best pay us by Alibaba Assurance on line, that’s an assurance for overseas customers. |

Kindly please provide the CNC Machining Parts drawings in PDF, if provide in STEP or IGS will be better. We'll review the drawings and send you a quote list within 24 hours.