Dongguan Jinjie Precision Hardware Co., Ltd |

|

Verified Suppliers

|

|

CNC Milling Parts Anodized Aluminum Metal Parts CNC Machining Services Parts

Dongguan Jinjie Precision Hardware Co., Ltd. is located in Dongguan City, the world manufacturing center. The factory was established in 2015 with a plant area of 3800 square meters. The company has a professional machining production team. The average core technical personnel have been in the industry for more than 10 years and specialize in processing customized precision parts.

The company has passed ISO9001 and ISO13485 quality system certification, and its customer industries include medical, electronics, aviation, automotive, semiconductor, optics, new energy, precision automation machinery, etc. The company's main equipment is imported CNC, CNC lathes, lathes, milling machines, internal and external cylindrical grinders, hand grinders, slow wire running, medium wire running, fast wire running, spark machines, micro-hole machines, two-dimensional, three-dimensional, height gauges and other advanced equipment processing equipment and testing equipment.

In contrast, CNC lathes are suitable for creating cylindrical shapes or parts that are symmetrical near their axis.

Nevertheless, CNC milling and turning machines can achieve tolerances as tight as ±0.001mm.

The company uses advanced imported high-precision production equipment, quality control inspection instruments, and reliable testing equipment to provide precision CNC milling and turning, and precision mechanical component processing services to global customers.

| Material | Aluminium 6060/6061/6063/7075/5052 etc |

| Stainless steel303/304/400/316,SteelQ235,4140,1045etc | |

Brass:C36000(C26800),C37700(HPb59),C38500(HPb58),C2200(CuZn37), C28000(CuZn40) etc, | |

| Copper,bronze,copper. | |

| Process | CNC turning,CNC milling, CNC grinding;CNC lathe machining, CNC boring;CNC drilling, surface treatment |

| Surface treatment | Hardness anodizing black/clear or other colors, steel oxidizing dark-blue, electro-polishing, electroless nickel plating, Chrome plating, silver plating, golden plating etc |

| Tolerance | +/-0.005mm or +/- 0.00019" |

| Certification | ISO9001:2016, ISO13485:2016 |

| Production capacity | depend on complicacy of different products and the quantity |

| Experience | 11 years of CNC machining products |

| Packaging | EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton or as per customes'requirement |

| Lead time | Sample 5-15 days;Bulk orders are determined according to customer requirements |

| Part size | Diameter from 0.5mm to 1000mm |

| Minimum Order | 1 PCS |

| Maine equipment | Machining center, CNC, Lathe, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine etc. |

| Testing facility | CMM, projector, roughness tester, hardness tester, concentricity tester. Height tester, . |

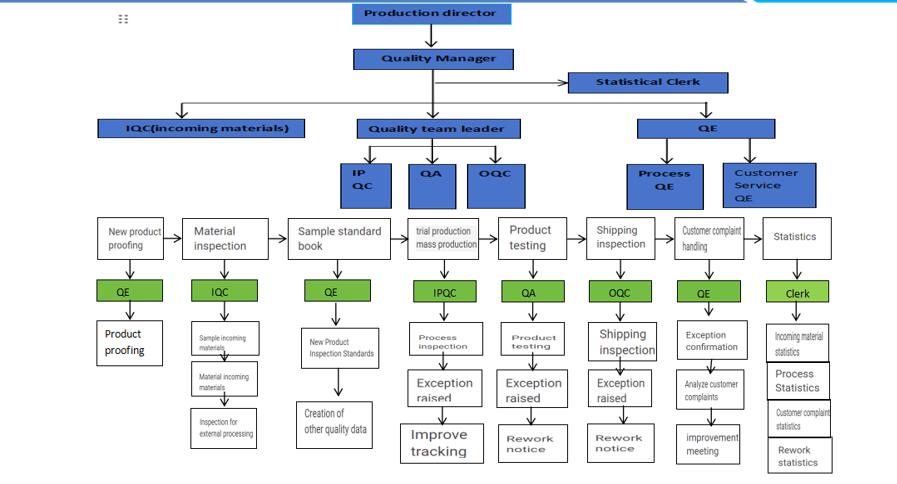

Our Quality and Lead Time Objectives:

1. Sample acceptability reaches 100%.

2. Qualified rate of finished products reaches 100%.

3. Punctual delivery rate reaches 100%.

1. Provide the detailed production schedule for each order.

2. Offering production status with video and photos for each component.

3. Manufacture the parts base on customers' drawings to meet the quality requirements and industry standard.

4. Over 99% orders can meet the lead time requirement.

5. Respond to the enquiry within 24 hours and offer the quotation within 48 hours.

6. Using the first-rank raw materials which also can be traced.

7. Provide the most competitive price with the high quality and service standard.

8. The most reasonable packing scheme for all products.

We can provide precision machining of steel, aluminum alloy, copper alloy, zinc alloy, plastic and castings and other materials, and provide free samples for new and old customers. If the above information is helpful to you, please contact us!

Certification:

Packaging:

1. Jinjie packaging is based on the highest industry standard;

2. Each part is packed independently.

Shipping:

FAQ:

Q1:Where is your factory? A:We are located in Shenzhen, Guangdong,China. |

Q2:What information do I need to provide to get a quote? A:Product drawings (material, structure, dimensions and surface treatment requirements, etc.) and MOQ. |

Q3:What's the MOQ? A:You can make as many pieces as you want. I just need to remind you that there is a world of difference between the price for 1 piece and that for 1000 pieces. |

Q4:Can you provide free samples? A:Of course, but you have to pay the shipping cost.(Our engineers work very hard to make samples. If there is no subsequent orders, I think they will be very sad.) |

Q5:Generally speaking, how long is the delivery time? A:Usually 5-15 days.It depends on the quantity of your order |

Q6:Is it safe to send my drawings to you?Will you give away the secrets of my design? A:Yes, we can sign the NDA in advance, before you send the drawings |

Q7:How do I know the status of my project without going to the factory? A:You can always ask our sales staff to provide you with photos and videos. |

Q8:There are other questions I'd like to know. A:Don't hesitate.Please contact us right away.It's our pleasure to talk with you. |