Henan Yuanda Boiler Co.,Ltd |

|

Automatic Feeding Horizontal Chain Grate 10 ton Coal Biomass Fired Steam Boiler

Brief intrduction:

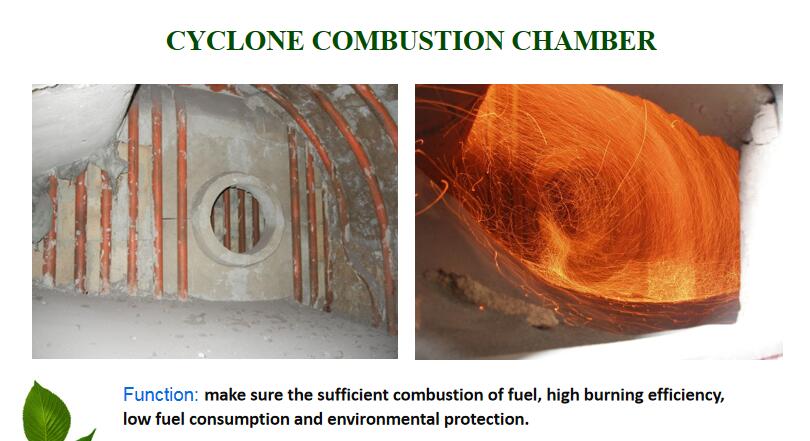

SZL series boiler is water tube chain grate double drum coal biomass boiler. The boiler is mainly composed of upper and lower drums, convection tubes, water-cooling wall tubes, down pipes and steam headers. 1-8tph boiler is package boiler and 8-35 tph is shop-assembled structure, which is composed of 2 parts, upper part is heat surface and lower part is combustion equipment. It has big furnace which has great apply for various type biomass fuel, like wood pellet, rice husk, bagasse, palm kernel shell, etc. The unique design of cyclone burn-out chamber makes the boiler with advantages of energy saving and environmental protection.

Basic specifications of 10 ton biomass fired steam boiler:

| No. | Name | Unit | Data | ||||

| 1 | capacity | t/h | 10 | ||||

| 2 | Rated Pressure | Mpa | 1.25 | ||||

| 3 | Feed water temperature | ℃ | 105 | ||||

| 3 | Steam temperature | ℃ | 194 | ||||

| 4 | Hydraulic test pressure | Mpa | 1.65 | ||||

| 5 | Water volumn | m3 | 8.35 | ||||

| 6 | Exhaust smoke temperature | ℃ | 159 | ||||

| 7 | Design efficiency | % | 86 | ||||

| 8 | Fuel consumption | kg/h | 2109.75 | ||||

| 9 | Fuel lowest heat value | MJ/kg | 12.66 | ||||

| 10 | Applied fuel | biomass, wood chip, rice husk, sawdust, coco shell | |||||

| 11 | Radiation heating area | ㎡ | 35.3 | ||||

| 12 | Convection heating area | ㎡ | 233.3 | ||||

| 13 | Economizer heating area | % | 279.04 | ||||

| 14 | Grate active area | / | 15.5 | ||||

| 16 | Boiler upper part dimension | mm | <1 | ||||

| 17 | Boiler grate part dimension | mm | 8870×3670×3462 | ||||

| 18 | Boiler upper part weight | ton | 24 | ||||

| 19 | Boiler main part weight | ton | 22.6 | ||||

| Note: The above fuel consumption is based on 16.63MJ/KG calories fuel, if the specification is improved, please refer to the updated data | |||||||

SZL biomass steam boiler design features:

Application field

Boiler system: we provide this biomass steam boiler with full set auxiliaries.

| Number | Item | Brand | Number | Item | Brand |

| 1 | Boiler proper | Yuanda | 8 | Induced fan | |

| 2 | Fuel feeder | 9 | Steam header | ||

| 3 | Electric control box | Yuanda | 10 | Feed water pump | |

| 4 | Economizer | Yuanda | 11 | Deaerator | Yuanda |

| 5 | Water treatment | Fleck | 12 | chimney | Yuanda |

| 6 | Water tank | 13 | Slag remover | ||

| 7 | Forced fan | 14 | Instrument&valves | ||

| 8 | Grate speed reducer | 15 | Cyclone Dust Collector |

After-sale service:

1. provide full range of original spare parts.

2. We will send engineers to your local project site to guide the installation and commissioning.

3. Our engineers will held a training for boiler workers to ensure the safe operation.

4. Free maintenance and repair for one year and lifelong service.

Why choose Yuanda Boiler?