Zhijing Precision Machinery (Shanghai) Co., Ltd. |

|

Tungsten carbide slitter saw blades

for packaging industry blade/ knife

custom order accepted

All of our products are of very good quality

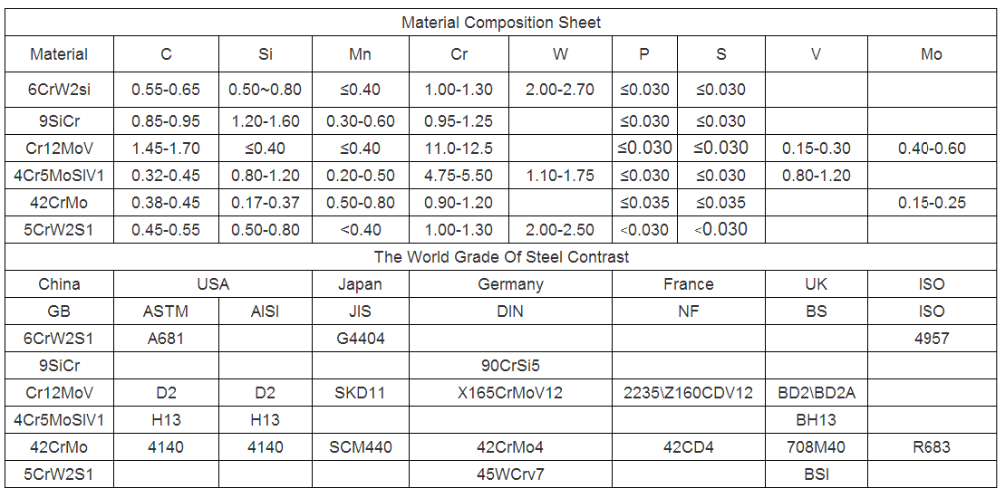

1. Material: Our materials are from reliable steel facories. Material quality warranted.

2. Processing: We have been manufacturing blades for more than 20 years. We pay attention to

the micro places when processing. And we are keeping improving the blades cutting efficiency and

the technical solutions for clients.

3. Our service: Technical solutions, fast response for the products inquiry, assist clients' requirements

on the after sale service offered.

Choose Zhijing is choose good quality

Tungsten carbide slitter saw blades!

Professional manufacturer of industrial blades ,such as slitter blades, shearing machine blades,

cutting paper blades, crusher blades ,shredder blades etc , Located in Shanghai City, China (mainland) ,

Zhijing has been committed to the research and development of various industrial blade, the main products

include: slitting machine blade, Slitter circular blade, slitting circular blade, shredder blades ,shear blades,

cut flat circular knife, crusher blades, shredder blades, wood cutting blades etc .

Our company pursuit of "super-sharp, high-precision, extremely durable" knife philosophy, dedication to

create each piece of mechanical blade, from the first sheet to the first one million tutte. Let's sophisticated

technology and strict attitude to provide you with top service!

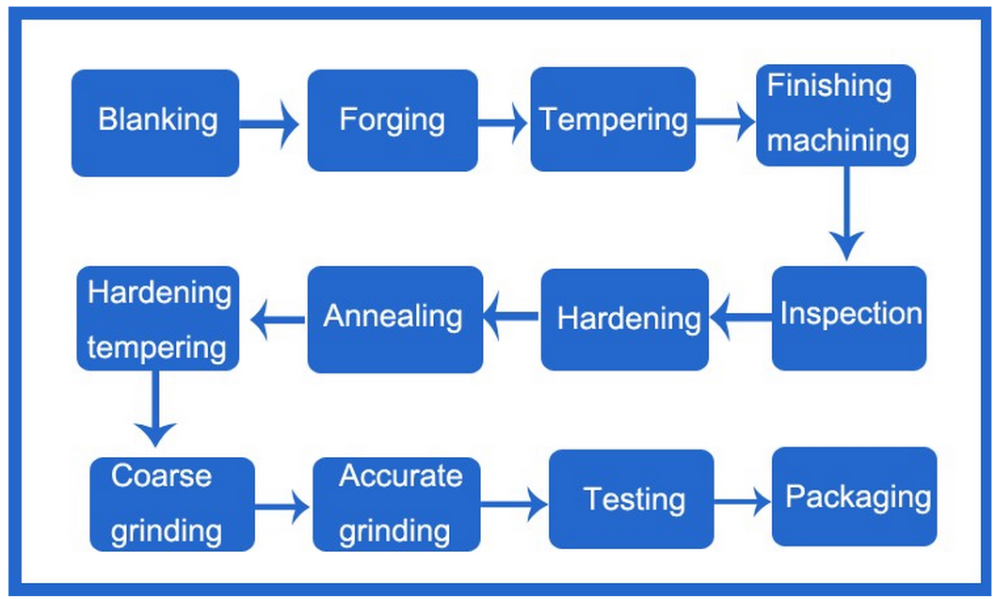

| 1. Blanking | Selecting material according the customers' request. |

| 2. Forging | Increasing the density of the material. |

| 3. Tempering | Lowering temperature for processing. |

| 4. Finishing machining | Making the material shaped |

| 5. Inspection | Checking the products if they are the same as the drawing. |

| 6. Hardening | Increasing the hardness of products and the material. |

| 7. Annealing | To incrase abrasion resistance, need to anneal thermal insulation for long time. |

| 8. Hardening and tempering | Hardening and tempering the parallel of products for processing. |

| 9. Coarse grinding | Coarse grinding the surface of products to be shaped. |

| 10. Accurate grinding | Supergrinding to incrase the precision and the parallel of products. |

| 11. Testing | Refusing the unqualified products into the market. |

| 12. Packaging | Different products, different packaging |

| 12. Packaging | Different products, different packaging |

| Material grade list | |||||||||

| Chinese Grade | Equal to ISO Category Number | chemical | Physical mechanical properties | Application | |||||

| composition | |||||||||

| WC | Co | Density | Bend Strength | Hardness | |||||

| % | % | g/Cm3 | N/mm2 | HRA | |||||

| YG3 | K01 | 96.5-97 | 3 | 14.9-15.3 | ≥1180 | ≥91.0 | It is suitable for the finishing of cast iron, non-ferrous metals, alloys and non-metallic materials, and semi-finishing vehicles for intermittent cutting. | ||

| YG6X | K10 | 93.5 | 6 | 14.8-15.1 | ≥1420 | ≥92 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron | ||

| YG6 | K20 | 94 | 6 | 14.7-15.1 | ≥1600 | ≥91 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | ||

| YG8 | K20-K30 | 92 | 8 | 14.5-14.9 | ≥1600 | ≥90 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials. | ||

| YG10 | K40 | 90 | 10 | 14.3-14.7 | ≥1900 | ≥89 | It is used for large batch production and has excellent strength and toughness. | ||

| YG10X | K40 | 89 | 10 | 14.3-14.7 | ≥2200 | ≥89.5 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | ||

| YG15 | K30 | 85 | 15 | 13.9-14.2 | ≥2100 | ≥87 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses | ||

| YG20 | K30 | 80 | 20 | 13.4-13.7 | ≥2500 | ≥85.5 | Stamping die, stamping watch parts, musical instrument spring piece; | ||

| YG20C | K40 | 80 | 20 | 13.4-13.7 | ≥2200 | ≥82 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die, warhead to the shell of the stamping die | ||

| YG30 | 70 | 30 | 12.75 | ≥2500 | ≥82.8 | High toughness | |||

We choose suitable packaging for the products

We now cooperating with the DHL, Fedex, UPS, TNT, special line which offer door to door

service, and the freight is very competitive, can save your money on shipping.

For large packaging size products, by air or by sea also avaliable, we will do as required

for clients.