Shenzhen Bicheng Electronics Technology Co., Ltd |

|

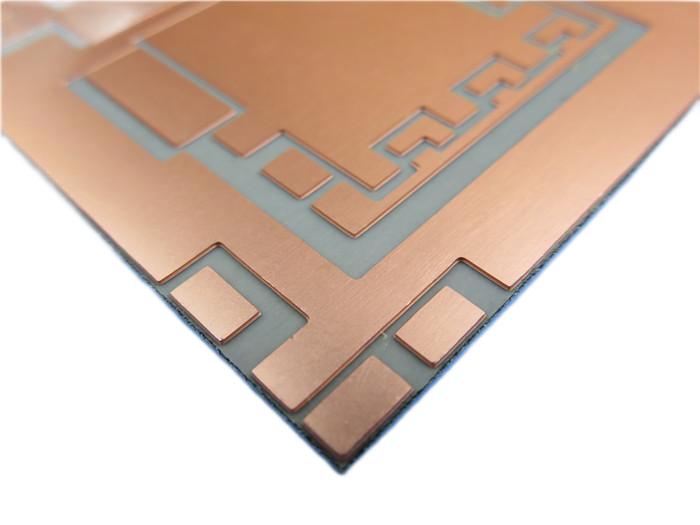

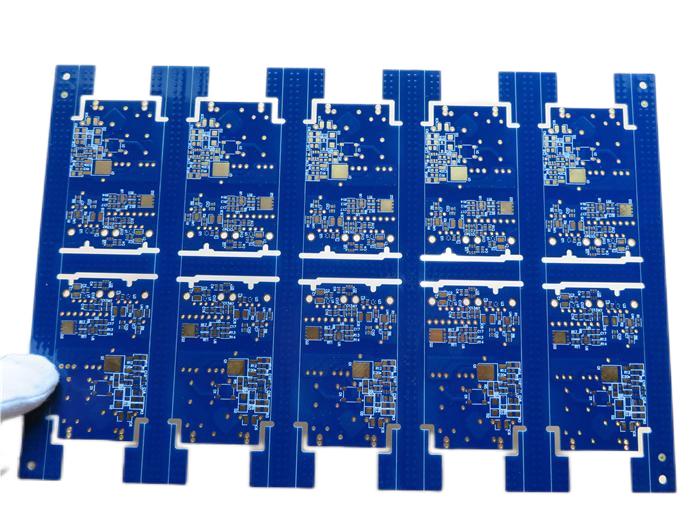

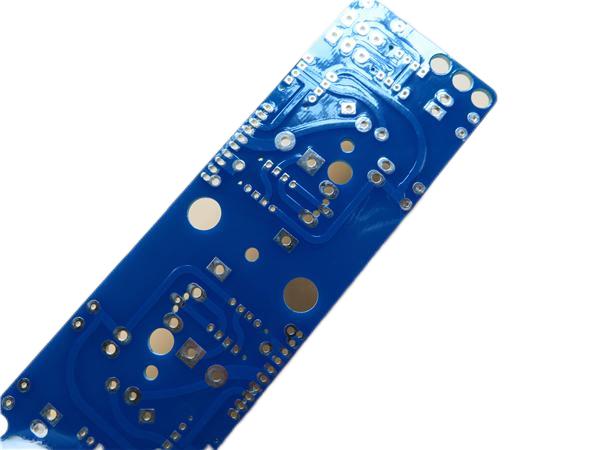

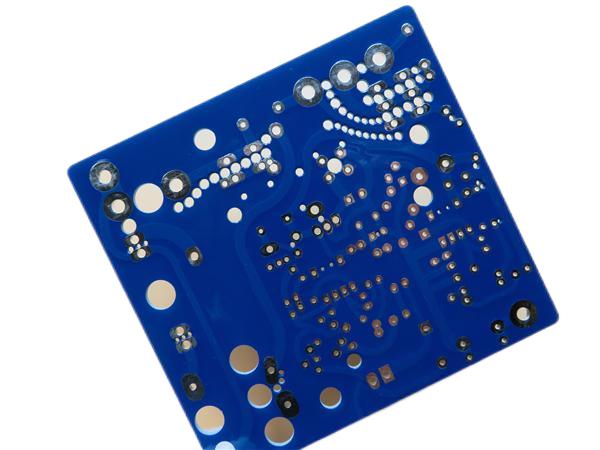

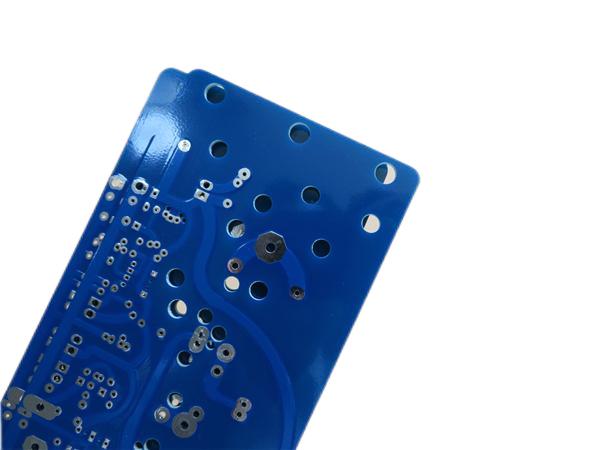

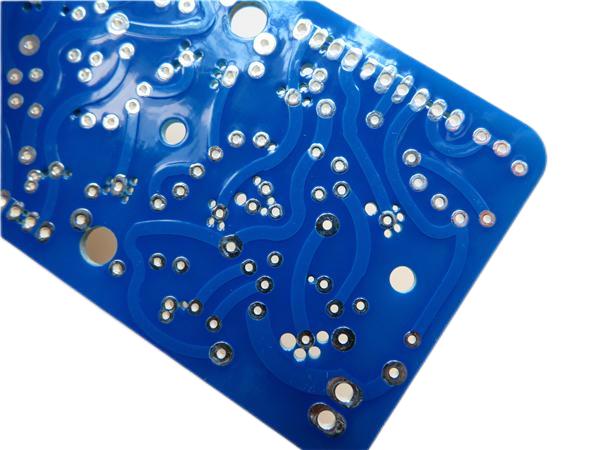

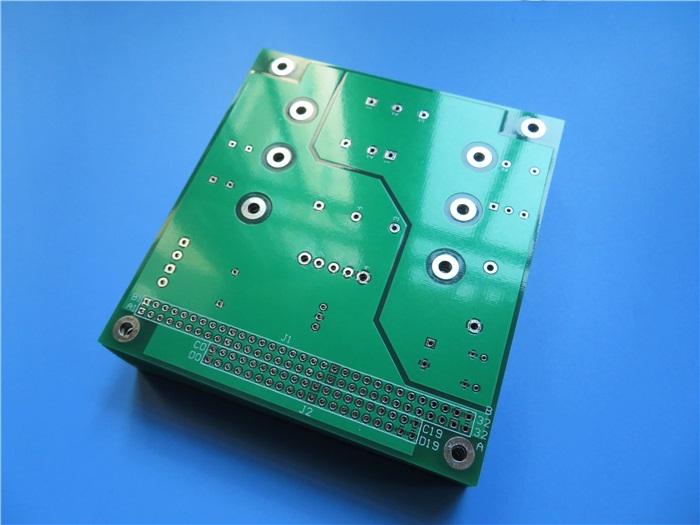

Heavy Copper PCB High Power Circuit Board Built On FR-4 With 3 Oz Copper

(Printed circuits boards are custom-made products, the picture and parameters shown are just for reference)

1.1 General description

This is a type of heavy copper PCB built on FR-4 substrate with Tg 135°C for the application of UPS systems . It's 1.6 mm thick with white silkscreen(Taiyo) on green solder mask (Taiyo) and HASL on pads. The base material is from ITEQ supplying 1 up PCB per panel. They're fabricated per IPC 6012 Class 2 using supplied Gerber data. Each 25 panels are packed for shipment.

1.2 Features and benefits

1. It's Lead free compatible.

2. Excellent wetting during component soldering and it can avoid copper corrosion.

3. Better heat dissipation of high heat generated by large current

4. UL, ISO14001, IATF16949 certified

5. Reliability test, insulation resistance test and ionic contamination test

6. Quick Lead time: 3-5 days

7. Customer complaint rate: <1%

1.3 PCB Specifications

| PCB SIZE | 97 x 99 mm=1PCS |

| BOARD TYPE | Double Sided PCB |

| Number of Layers | 2 Layers |

| Surface Mount Components | YES |

| Through Hole Components | YES |

| LAYER STACKUP | copper ------- 105 um (3 oz) |

| FR-4 1.5 mm | |

| copper ------- 105 um (3 oz) | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 12 mil / 8 mil |

| Minimum / Maximum Holes: | 0.65mm / 3.175mm |

| Number of Different Holes: | 9 |

| Number of Drill Holes: | 87 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 0 |

| Impedance Control: | 0 |

| Number of Gold finger: | 0 |

| BOARD MATERIAL | |

| Glass Epoxy: | FR-4 Tg 135℃, er<5.4.IT-140, ITEQ |

| Final foil external: | 3 oz |

| Final foil internal: | 3 oz |

| Final height of PCB: | 1.6mm ±0.16 |

| PLATING AND COATING | |

| Surface Finish | HASL 6.25um |

| Solder Mask Apply To: | TOP and Bottom, 12micron Minimum |

| Solder Mask Color: | Green, PSR-2000 GT600D, Taiyo Supplied. |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | TOP and Bottom. |

| Colour of Component Legend | White, IJR-4000 MW300, Taiyo Supplied. |

| Manufacturer Name or Logo: | Marked on the board in a conductor and leged FREE AREA |

| VIA | plated through hole(PTH) |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" |

| Board plating: | 0.0029" |

| Drill tolerance: | 0.002" |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

1.4 Applications

Power Inverters

AC to DC Power Converter

UPS Uninterruptible Power Supply

RACk Mount Power Supply

Cosel Power Supply

AC/DC Switching Power Supply

Power Supply Inverter

HVAC systems

DC To DC Converters

5000 Watt Inverter

1.5 Heavy Copper

Generally, the PCB copper foil with a nominal thickness of 105 μm or over is collectively referred to as a thick copper foil (including the surface-treated electrolytic copper foil and rolled copper foil). The PCB and copper foil manufacturing industry domestically and abroad are more accustomed to specifically divide the thick copper foil into three varieties based on its nominal thickness, the one with thickness of 105μm (≥ 3oz) ~ 240μm or over is called thick copper foil; the one with thickness of 300μm or over is called super-thick copper foil; the one with thickness of 600μm and above is referred to as super MAX copper foil.

The thick copper foil and super-thick copper foil belong to a kind of special PCB copper foil. In addition to its conventional electrolytic copper foil (or rolled copper foil) performance, it also has such special performance as the conducting layer of high current board or the inner core cooling metal layer of the high-current PCB, and other special performance requirements. These special performance requirements are to meet the application conditions, processing conditions and other aspects from its downstream products. The application performance requirements of it is mostly expressed in the characteristics that the conducting circuit of thick copper can stably carry high current, and can better distribute high heat generated by the loaded high current in a substrate.

In recent years, with the expansion of application field of heavy copper printed circuit board, and the increase of production and sales, the production and sales of thick copper foil has also been significantly improved. According to statistics, its production and sales have accounted for 5 ~ 6% of the world's production and sales of electronic copper foil, which is 17,000 ~ 20,000 tons / year.

1.6 More Displays of Heavy Copper PCB