Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd |

Low Alloy Steel Drain Pipe Direct Square To Square Pipe Mill ERW Steel Square Tube Mill

Direct Square to Square Pipe Mill Introduction:

It is directly roll the steel strip and bend it to square & rectangular shape, then weld it to finish the formation.It has several distinct advantages:

1.Compare with round into square & rectangle forming way, this

way is better for the shape at the edge of cross section,

comparatively, semidiameter of inner arc is Small, and the brim is flat, outlook is

regular.

2.the whole line load is low, especially the sizing parts.

3.The width of steel strip is small about 2.4-3% than round into square & rectangle, it can save the

consume of raw material.

4.It adapt the multi-point bending way, avoid the axial force and

side abrasion, reduce the forming step while ensure the quality,

meanwhile it reduce the power wastage and roller abrasion.

5.It adapt the combined type roller on the most of the stands, it

realize that one set of roller can produce dozens of square &

rectangle pipe with different specification, it decrease the store

of roller, low the cost about 80% on roller, Fast the bankroll

turnover, short the time one new product design.

Square Tube Mill Product Parameter:

| Product & yield | Round Pipe | 32mm-76mm Thickness:0.5mm-4.0mm |

| Square & rectangle tube | 25mm×25mm-60mm×60mm Thickness:0.5mm-4.0mm | |

| Length | 6m-12m Length Tolerance:±3mm | |

| Production Speed | 120m/min | |

| Production Capacity | 30000ton/year | |

| Consumption | Mill Installed Capacity | 220kw |

| Line Area | 85m(length)×7m(width) | |

| Worker | 6-8 workers | |

| Raw Material | Carbon Steel Coil | Carbon steel coil Q235B(ASTM GR·D,σs 230) |

| Width | 100mm-240mm Thickness:0.5mm-4.0mm | |

| Coil ID | 580-700mm | |

| Coil OD | Max 1800mm | |

| Coil Weight | 30.0t |

Square Tube Mill Auxiliary Machines:

Customers can trust us to buy the auxiliary machines. Our choice of suppliers for the auxiliary parts is made after 22 years of experience.

Un-coiler

Function: Used for supporting strip steel coil and open it as strip steel so as to make preparation for the pipe forming process.

Shearing butt welding

2 Types: Automatic & Manual

Function: Shear & end welder parallel cuts the head of the strip coming out of uncoiler and the tail of the strip steel going into the accumulator, and weld them together to form a smooth and continuous line of strip steel.

Strip Accumulator

Function: Accumulator is used to accumulate strip steel from uncoiler and provide strip steel to forming unit. It leaves time for the shear & end welder for strip welding and stores certain amount of strip for continuous forming.

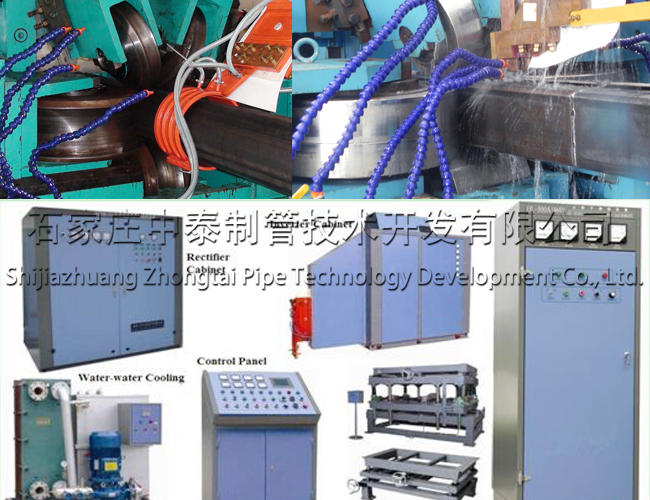

Solid State High Frequency Welder

Function: The welder is used for welding edge heating with high-frequency heating device. The whole set of solid-state H.F welder comprises of rectifying cabinet, inverter, output cabinet, connecting optical fiber, closed loop water cooling system, central operator console, and mechanical adjustment device.

Saw Cutting System

Function: Flying saw is used to cut tube during static and motion status in continuously production into desired length.

Straightening Machine

Function:Straightening machine is a finishing equipment for the high-frequency straight seam welded pipe production line, which is used to straighten the steel pipe to eliminate the stress and bending after the steel pipe forming and welding.

Automatic Stacking and Packing Machine

Function: Electrical control using PLC control, touch screen, to achieve human-computer dialogue, manual, automatic between the free conversion.

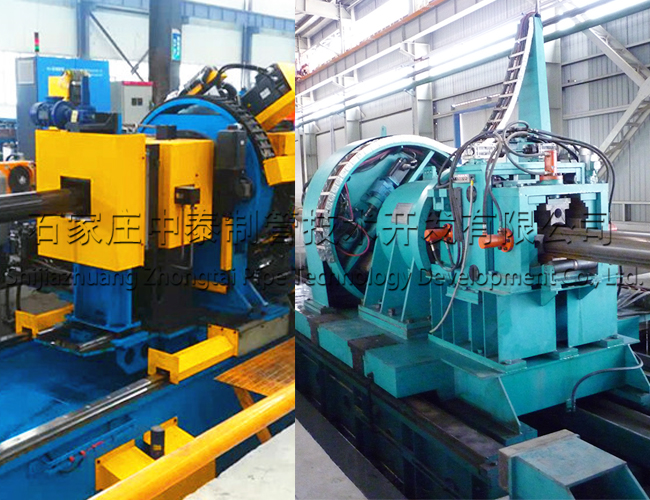

Square Tube Mill Details Images:

Forming Section

Function: to form the steel strips into a round shape and ready to be welded.

Advantage:

>Advanced forming technical

>One-stage molding platform

>Reliable quality gearbox

>Siemens Beide motor

Welding Section

Function: To weld the edges of the steel strips together by H.F. Welder (the H.F. Welder is not included).

Forming & Sizing Mill

Function: After welding, the pipes are almost the round shape, but it still needs to be modified into a regular round shape.

Initial Straightening Machine

Function: Another name is Turks head. It is used to rough-straighten the welded steel tube. It consists of two four-roller straightening machines, with its head able to revolve and move horizontally. It utilizes three-point method to straighten steel tube.

Company Introduction

FAQ:

Q:Are you manufacturer?

A:Yes,we are manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and

Moulding ). We also have our own R&D department. Welcome to

visit us.

Q:What kind of payment term do you do?

A: We do T/T and L/C.

Q:What info do you need before giving me the price and proposal?

A: Since we design individual machine based on our customer's

requirement, we need your desired

products' basic dimension, including all the pipe diameter(or tube length), thickness range , usage,

raw material steel grade, coil weight, and degree of automation.

Q: What should I do if I just start a new business?

A:Contact us immediately ,we provide free consultant for pre-sales

service .Also we can help you

solve the raw material (steel coil) purchase, worker training,

international market price, and more.

Q:How do you do QA?

A:We have special team to do strict QA,this is one of our

strengths:

(1)Every gear box will be tested for 8 hours with oil inside to

guarantee there is no leak.

(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure its in the range of

tolerance critical parts will be

inspected for all dimensions.

Q:Why I should choose you? what are the differences between you and

other Chinese suppliers?

A:We are concentrate on pipe making machines for more than 20

years. We have constructed many

steady trading partners in Asia,Africa, middle east, Europe, and South America throughout the years.

Our innovative designed production line and each single unit of the production line are not only

economical but also practical.