Active Member

|

[China]

Address: No.322 East Zhongshan Road, Shijiazhuang,China

Contact name:Peter

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd |

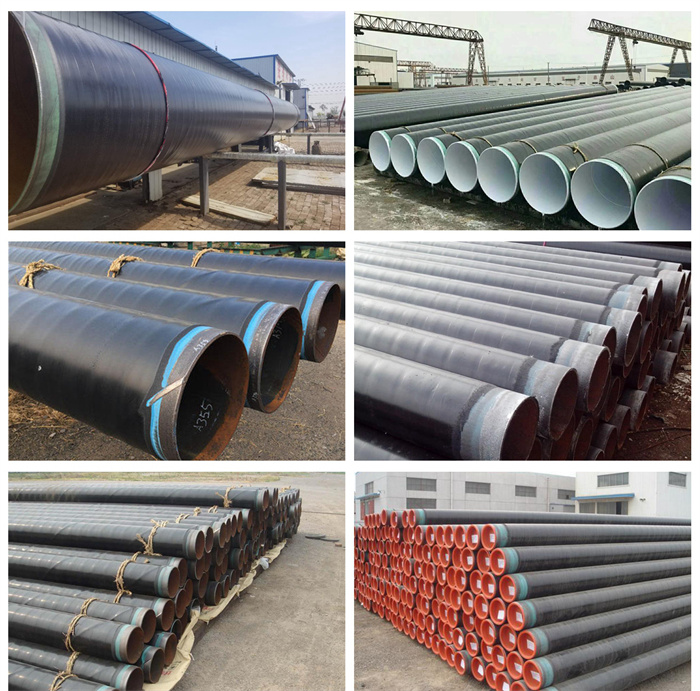

Tube Conveyor Line Petroleum And Gas Oil Casing High-Grade Steel Pipe API 5L Standard Tube Mill

Product Introduction

The high frequency welded pipe line is a high pressure, high

rigidity welding line for transporting oil and gas pipelines that

meets API standards.

There is a big difference in the production process between the

welded pipe production line that meets API standards and the

low-pressure fluid conveying pipe production line:

1. The pressure of welded pipes meeting API standards is much

higher than that of low-pressure fluid conveying pipes;

2. Pipe welds that meet API standards must be heat treated;

3. Generally, the wall thickness and steel grade of welded pipe

that meet API standards are much higher than that of low-pressure

fluid conveying pipe, so it is also called high-pressure

high-strength pipe;

4. Welded pipes that meet API standards must have perfect finishing

equipment.

API Pipeline Process

Loading coil - Uncoil - Straighten head - Ultrasonic plate testing

- Shearing and butt welding - Spiral loop - Edge planing - Forming

- High frequency welding - Remove inside and outside the burr -

Ultrasonic weldseam inspection - Polishing - Intermediate frequency

annealing - Air cooling and water cooling - Correct reverse -

Sizing finishing - Turkey head straightening - Length cut -

Sampling test - Straightening - Tube end facing - Hydrolic test -

ultrasonic flaw detection - Coating - Marking - Packaging -

Warehousing

Features of Production Line:

1. High strength, high toughness, and corrosion resistance of raw

materials;

2. The equipment has high strength, high precision and occupies

large ground;

3. The equipment has the characteristics of fast roll change

without dismantling the main shaft and archway, and the common rate

of roll mold is high;

4. Multi-procedure inspection and flaw detection are required; The

finishing quality of the pipe end is required to be high.

5. Production of high steel grade, large diameter, large wall

thickness steel pipe products.

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's

requirements, we need your desired products' basic dimensions,

including all the pipe diameter(or tube length), thickness range,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for

pre-sales service. Also, we can help you solve the raw material

(steel coil) purchase, worker training, international market price,

and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our

strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to

guarantee there is no leak.

| Model List | ||||

| Model | Round pipe mm | Square pipe mm | Thickness mm | Working spead m/min |

| ERW20 | Ф8-Ф20 | 6x6-15x15 | 0.3-1.5 | 120 |

| ERW32 | Ф10-Ф32 | 10x10-25x25 | 0.5-2.0 | 120 |

| ERW50 | Ф20-Ф50 | 15x15-40x40 | 0.8-3.0 | 120 |

| ERW76 | Ф32-Ф76 | 25x25-60x60 | 1.2-4.0 | 120 |

| ERW89 | Ф42-Ф89 | 35x35-70x70 | 1.5-4.5 | 110 |

| ERW114 | Ф48-Ф114 | 40x40-90x90 | 1.5-4.5 | 65 |

| ERW140 | Ф60-Ф140 | 50x50-110x110 | 2.0-5.0 | 60 |

| ERW165 | Ф76-Ф165 | 60x60-130x130 | 2.0-6.0 | 50 |

| ERW219 | Ф89-Ф219 | 70x70-170x170 | 2.0-8.0 | 50 |

| ERW273 | Ф114-Ф273 | 90x90-210x210 | 3.0-10.0 | 45 |

| ERW325 | Ф140-Ф325 | 110x110-250x250 | 4.0-12.7 | 40 |

| ERW377 | Ф165-Ф377 | 130x130-280x280 | 4.0-14.0 | 35 |

| ERW406 | Ф219-Ф406 | 170x170-330x330 | 6.0-16.0 | 30 |

| ERW508 | Ф273-Ф508 | 210x210-400x400 | 6.0-18.0 | 25 |

| ERW660 | Ф325-Ф660 | 250x250-500x500 | 6.0-20.0 | 20 |

| ERW720 | Ф355-Ф720 | 300x300-600x600 | 6.0-22.0 | 20 |