Active Member

|

[China]

Address: No.322 East Zhongshan Road, Shijiazhuang,China

Contact name:Peter

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd |

|

Trip Butt Welding Machine Welder Argon Welding Welder Butt Welding Machine Shear End Welder

Introduction:

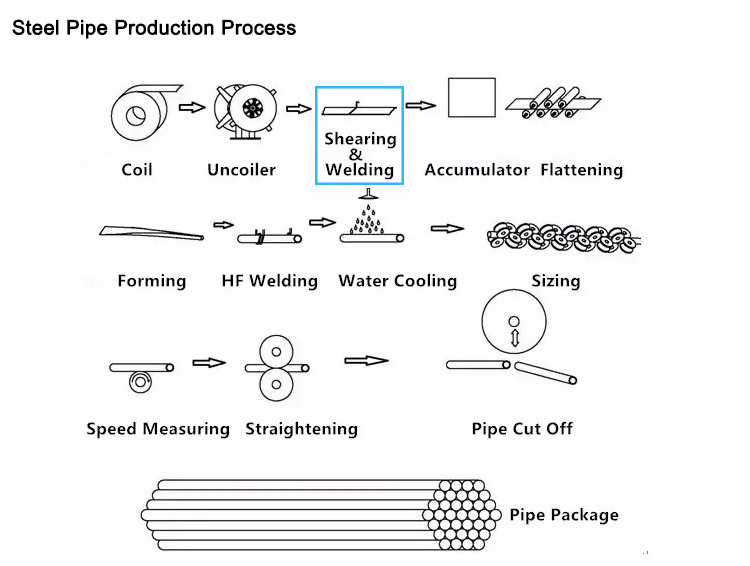

The equipment is used for shearing and welding of welded pipe sets. The equipment is an integrated automatic equipment designed for shearing and butt welding of thin plate materials. The equipment has small space occupancy, large shear force, can be moved at will. It can shear and butt weld sheet workpiece of 0.1-3mm thickness.

Automatic welding machine features:

The use of advanced technology shear, shear mouth smooth without burr; Strip positioning, by foot switch control cylinder work, easy to use, fast and reliable; Advanced water-cooled welding machine is adopted for the weld of the strip. The weld is flat and no grinding is required, which reduces the impact force caused by the failure of the strip during traction. Good weld quality; The whole welding operation is automatic.

The automatic butt welding machine can be used in pipe welding production line, rolling mill production line and other continuous production line with metal strips as raw material, which can complete the cutting and welding of the strip. The strip that can be shear welded includes: plain carbon steel, stainless steel, copper, aluminum, and other metals.

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's

requirements, we need your desired products' basic dimensions,

including all the pipe diameter(or tube length), thickness range,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for

pre-sales service. Also, we can help you solve the raw material

(steel coil) purchase, worker training, international market price,

and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our

strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to

guarantee there is no leak.