Industrial Stainless Steel Water Pipe Making Machine / Tube Mill

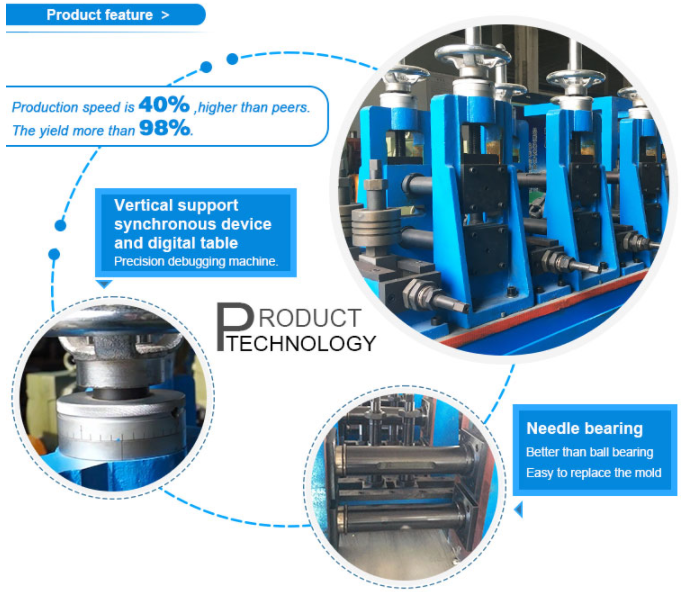

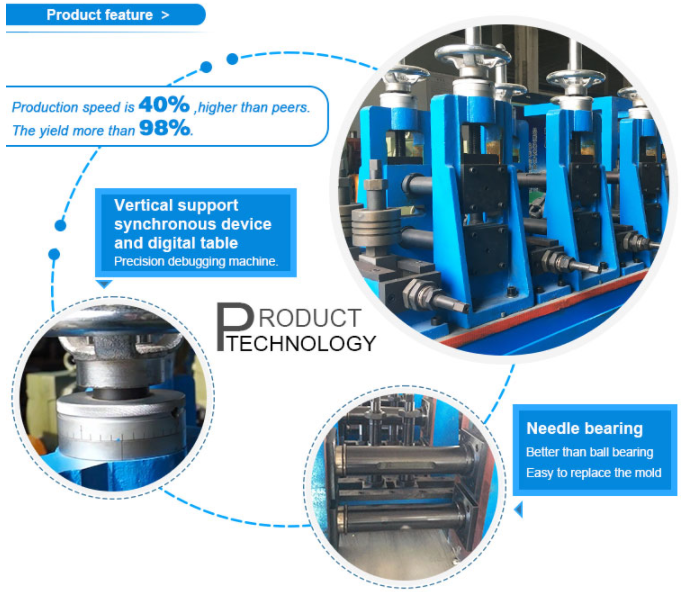

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd offers

different stainless steel tube mills, covering the range from 8mm to 50mm, and thickness from 0.5mm to 3.0mm for round pipe, square pipe, rectangle pipe, oval pipe, and other

irregular pipes as well.

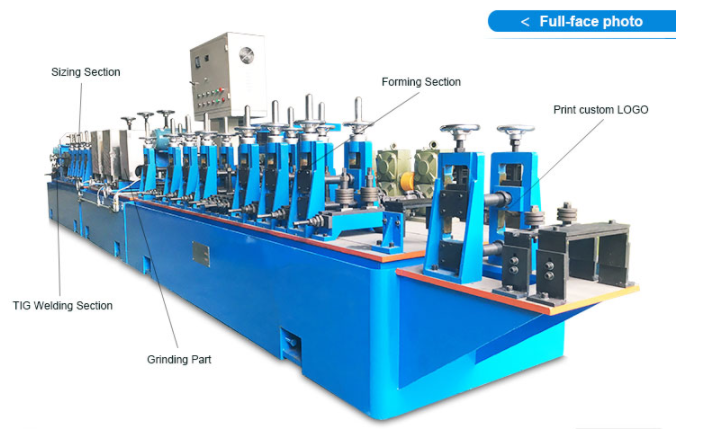

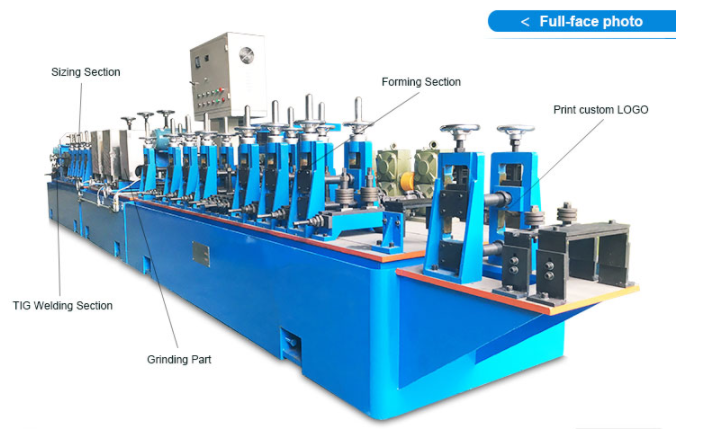

ZTZG series stainless steel welded pipe production lines are mainly

for the production of stainless steel and carbon steel thicker

pipes (round pipes ) mainly used in industrial areas or high

requirements in the decorative areas.

Product Description

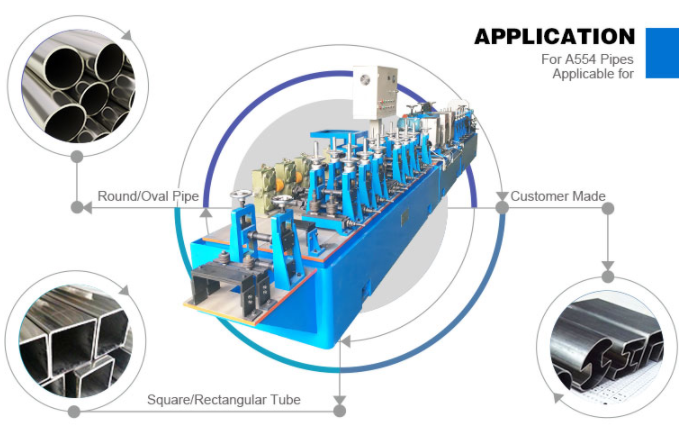

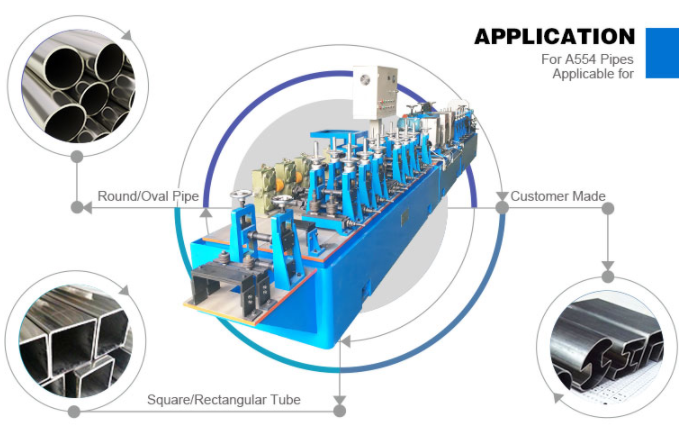

Application

Steel Pipe Making Machine not only can make round pipe, square

pipe, rectangle pipe, oval pipe, and other irregular pipes as well.

The finished pipe/tube used for decoration, such as furniture, hand

railing, household electric appliance, construction pipe.

Size Information

| | | | | | Voltage | Application |

| | | | | | 220V/380V/

415V/440V | Building

construction,

furniture,hand railing, fence,

household,

Curtain pipe etc |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

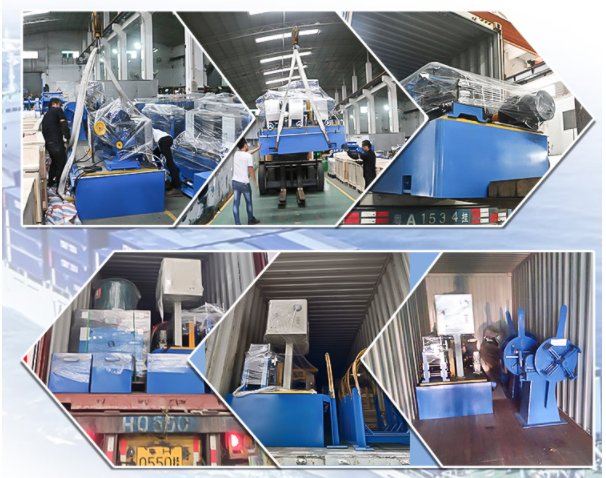

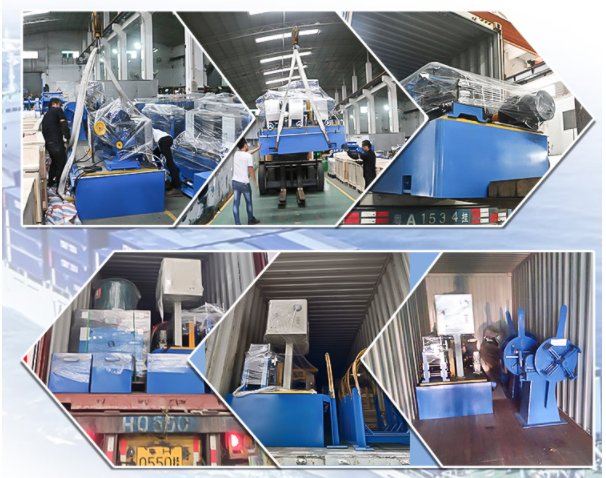

Packing&Shipping

After Sales Service

Committed to Providing Good Service

1.Test the tube mill machine before shipment

2.Provide technical guidance related to use the tube making machine

3.Provide the spare parts at cost price after the warranty period

4.Collect the feedback for the tube mill machine working

5.Provide long-term technical assistance

6.Offer a professional engineer to help you improve the output,

reduce the waste and decrease the cost.

Company Introduction

Q:Are you manufacturer?

A:Yes,we are manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q:What kind of payment term do you do?

A: We do T/T and L/C.

Q:What info do you need before giving me the price and proposal?

A: Since we design individual machine based on our customer's

requirement, we need your desired products' basic dimension,

including all the pipe diameter(or tube length), thickness range ,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A:Contact us immediately ,we provide free consultant for pre-sales

service .Also we can help you solve the raw material (steel coil)

purchase, worker training, international market price, and more.

Q:How do you do QA?

A:We have special team to do strict QA,this is one of our

strengths:

(1)Every gear box will be tested for 8 hours with oil inside to

guarantee there is no leak.(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure its in the range of

tolerance critical parts will be inspected for all dimensions.

Q:Why I should choose you? what are the differences between you and

other Chinese suppliers?

A:We are concentrate on pipe making machines for more than 20

years. We have constructed many steady trading partners in

Asia,Africa, middle east, Europe, and South America throughout the

years. Our innovative designed production line and each single unit

of the production line are not only economical but also practical.