ZHEJIANG XINCHOR TECHNOLOGY CO., LTD. |

|

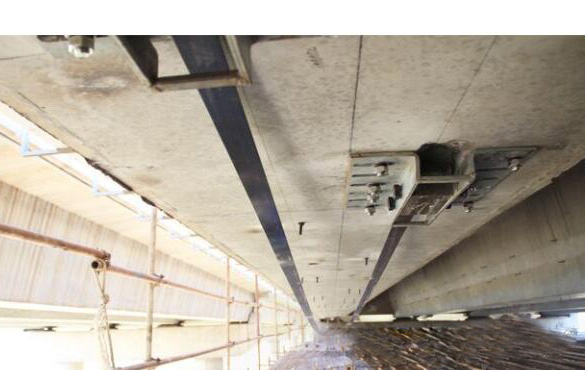

Crack Repair Prestressed Carbon Fiber Strip With High Strength

Crack Repair Carbon Fiber Reinforced Polymer Prestressed Carbon Fiber Strip With High Strength

Advantages

Approved by GB50367-2013/GB50728-2011/GB50550-2010

High Strength

Light Weight

Non-corrosive

Alkali Resistant

Typical Data

Tensile Strength

Mean Value 4.49ⅹ105psi(3100MPa)

Design Value 406ⅹ105psi(2800MPa)

Modulus of Elasticity

Mean Value 23.9ⅹ106psi(165,000MPa)

Design Value 23.2ⅹ106psi(160,000MPa)

Elongation at Break 1.7%

Temperature Resistance >300°F(>150℃)

Thickness 1.2mm

Fiber Content >68%

Density 0.058 lbs./in3 (1.6g/cm3)

Shelf Life: Unlimited (no exposure to direct sunlight)

Color: Black

| Item No. | XQ-P12/14/10/20/30 |

| Description | Carbon fiber reinforced polymer CFRP strip/sheet/laminates |

| Material | 12K Unidirectional Carbon Fiber |

| Thickness | 1.2mm, 1.4mm, 1.0mm,2.0mm, 3.0mm |

| OEM/ODM | Yes |

| Packing | Carton |

| useage | Structural Strengthening |

How to Use CFRP Laminate

• Setting out according to design

• Polish the surface of concrete surface

• Prepare ingredients

• Applying adhesive

• Installation the carbon fiber strip

• Maintenance

Key Characteristics of CFRP Strip

• High strength, high modulus

• Light weight

• Easy to install

• Easy to check after construction

• Environmental friendly

• Outstanding fatigue resistance, alkali resistance, acid resistance

.

Packaging:

The 2” (50 mm) wide plate is furnished in 250 ft (75 m) spools.

The 4” (100 mm) wide plates are furnished in 300 ft (90m) spools.

Surface Preparation:

• Surfaces to receive CFRP Plate laminates must be clean and sound. It must be dry and free of frost. All dust, laitance, grease, curing compounds, waxes, deteriorated materials, and other bond inhibiting materials must be removed from the surface prior to application.

• Large voids should be patched using an approved repair mortar. Uneven areas should be leveled with an appropriate leveling mortar or putty.

• Repair all cracks per project specifications.

• Sandblast, pressure wash, shotblast or use other approved mechanical means to achieve an open-pore texture with a concrete surface profile of CSP 3 or better (ICRI).

• The adhesive strength to the concrete may be verified after surface preparation by random pull-off testing

(ACI 503R) at the discretion of the engineer. Minimum

tensile strength of 200 psi must be achieved

• Scuff sand one side of the FRP laminate plate and

clean with acetone or other solvent to remove carbon dust.

Epoxy Mixing:

XQ-JGN31P epoxy is recommended for priming of substrate surface. Epoxy adhesives must be mixed according to the manufacturer’s specifications to achieve a homogeneous mixture.