Active Member

|

[China]

Address: No.10 Building, Shuntai Square, Licheng District, Jinan City, China

Contact name:CHEN Bo

SHANDONG SMART MACHINERY CO., LTD. |

|

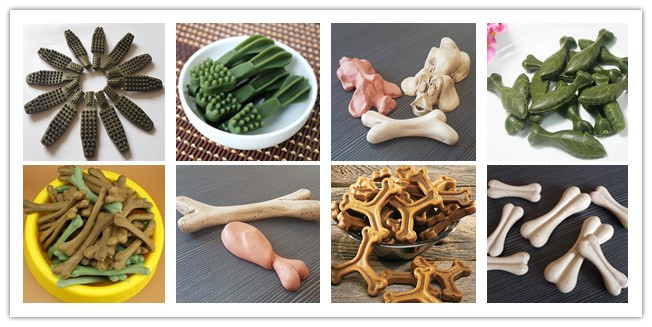

Pet Treats Injected Molding Machine is special machinery for

producing pet snacks. With such machine, various shapes can be

made, such as hedgehog, crocodile, dog, bone, pork ears, barrel,

etc.

The shapes of pet treats are very lovely and it is a ideal

encouragement to dogs and cats while they learn a new action or do

well in some exercises and games. Also, we can provide different

recipes to meet various market demands.

Pet treats injection machine can use the granular material made by

the extruder to produce the pet chews. Through high temperature and

high pressure, the pet chews molding machine will mold different

shapes.Such as bone, toothbrush, Mace, hedgehog, crocodile, dog,

pork ears, barrel and so on.The pet chews is a kind of pet toys or

pet food. There are many shapes of the pet chews, such as bone,

ball, ring, stick, shoes and particle.The pet chews are

high-protein and nutritional meat for dogs to eat.

a. Raw Materials: adopts corn flour, fish meal as raw materials

b. Products: different shapes are made by adjusting the dies from extruder

c. Flow chart:

Mixing system---Extrusion system---Injection system---Molding system---Packing system

d. Voltage : Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers` Local voltage according to different countries

The DM “ADvanced” Series of machines offers even greater high-speed

performance and increased precision, made possible by the

industry's highest-speed servo control circuit.

This advanced technology, has been accumulated over many years and

results in injection molding expertise that is the envy of the

industry.

Faster and more accurate, the DM Series achieves the highest levels

of productivity and reliability.

An industry pioneer, Smart Machinery has extensive experience in

manufacturing large electric molding machines.

The newly released, second-generation large electric servo drive

molding machine promises to deliver measurable improvements in

productivity, quality, and economy.

This latest improvement retains our time proven toggle clamping

unit, which for many years has delivered "faster cycle times" and

"unparalleled energy savings."

SMART has produced a super-advanced all-electric vertical type

injection molding machine - it is faster, more precise, and more

compact.

The DM series machines have been evolving to mach the needs of

today and beyond: They display high productivity on in-line

assembly.

Using the advanced technologies that have been fostered for many

years and are unique to SMART, we have achieved high-precision

injection molding.

Technical Parameter

1. It comes with user-friendly microprocessor controller with these

following features;

2. Dust, oil proof and colorful touch switch control panel.

3. El display of pressure, speed, time and distance for each

motion.

4. Equipped with 4 stages injection, 3 stages holding pressure and

3 stages back pressure.

5. PID barrel temperature control: temperature abnormal &

electrical wire disconnection alarm.

6. SSR-solid state temperature controller.

7. Screw cold start protection.

8. Abnormal shot detection.

9. Output quantity and packaging quantity preset.

10. Clamping, injection and ejection (option), and carriage action

(option) by linear potentiometer.

| Item | Name of item | Unit | DM268B-I |

| Injection Unit | Screw Diameter | mm | 55 |

| Screw L/D Ratio | Ratio | 20 | |

| Injection Volume (Theoretical) | cm | 601 | |

| Injection Weight (PS) | g | 548 | |

| Injection Pressure | Mpa | 185.1 | |

| Injection Rate into Air | g/s | 223.7/276.1 | |

| Injection Stroke | mm | 256 | |

| Injection Speed | Mm/s | 95/116 | |

| Screw Speed | rpm | 201/246 | |

| Clamping Unit | Clamping Force | KN | 2600 |

| Clamping Stroke | mm | 550 | |

| Space Between Tie-bars | mm×mm | 580 x 580 | |

| Max. Mould Height | mm | 600 | |

| Min. Mould Height | mm | 250 | |

| Ejector Stroke | mm | 160 | |

| Hydraulic Ejection | KN | 68 | |

| Ejector Rob Quantity | pcs | 9 | |

| Others | Max. Pump Pressure | Mpa | 17.5 |

| Pump Motor Power | kw | 22/30 | |

| Heater Power | kw | 15.9 | |

| Hopper Volume | L | 50 | |

| Oil Pump Volume | L | 550 | |

| Machine Weight | t | 8.5 | |

| Mould Positioning Ring Diam | mm | 160 | |

| Sphere Radius | mm | SR10 | |

| Machine Dimension | m x m x m | 5.82 x 2 x 2 |

Any interest for this dog treats injection molding machine, please be free to contact us for best quotation!