Zhongxing Shiqiang Technology (Tianjin) Co., Ltd. |

|

Verified Suppliers

|

|

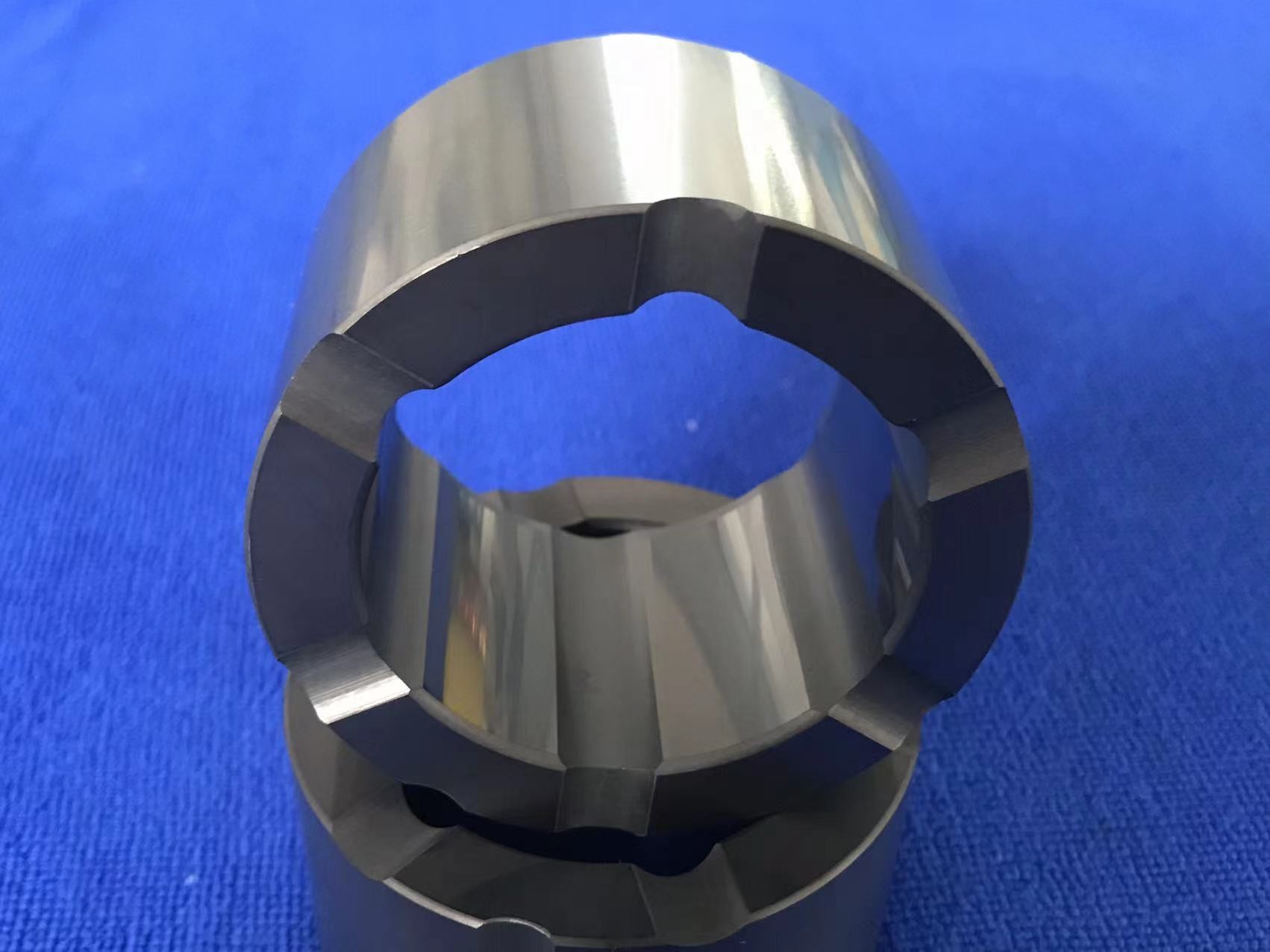

Ceramic Sliding Bearings are custom-made products developed to meet the unique needs of machinery. With a long lifespan, high durability, low friction, and high pressure tolerance, Ceramic Sliding Bearings are a perfect fit for a variety of machinery applications. The ceramic material is resistant to wear and tear, ensuring long-term performance. The low friction also enables the bearings to work smoothly without any problems. Additionally, the high pressure ratings allow for heavy and demanding applications. With Ceramic Sliding Bearings, machinery will be able to operate effectively and efficiently for a long time.

Ceramic sliding bearings also offer reduced friction and wear. The smoother and harder surfaces of ceramic materials reduce friction and wear between the bearing and the component it supports, resulting in improved performance and longer lifespan for the pump and its components.

Another benefit of ceramic sliding bearings is their high temperature tolerance. Ceramic materials can withstand high temperatures without degrading, making them ideal for use in high-temperature applications such as engine components and industrial machinery.

Ceramic sliding bearings are also much stronger and more durable than traditional steel bearings, which makes them ideal for high-stress applications where strength and durability are critical. Additionally, ceramic materials are much lighter than steel, which can reduce the overall weight of the pump and improve performance in applications where weight is a concern.

Overall, ceramic sliding bearings are a high-performance component that can provide improved corrosion resistance, reduced friction, high temperature tolerance, high strength and durability, and lightweight over traditional steel bearings. They areideal for use in applications where traditional steel bearings may not provide the necessary performance or durability. When choosing ceramic sliding bearings, it is important to select a high-quality ceramic material and ensure proper installation and maintenance to maximize their benefits and lifespan.

| Property | Value |

|---|---|

| Material | Silicon Carbide, SSIC |

| Structure | Sliding Bearing |

| Corrosion Resistance | High |

| Noise | Low |

| Friction | Low |

| Load Capacity | High |

| Temperature | High |

| Maintenance | Low |

| Application | Machinery |

| Lifespan | Long |

| Durability | High |

Ceramic Sliding Bearing is a kind of bearing with high-performance and low-friction. It is made of Ceramic material and is mainly applicable to machinery. It is designed according to the drawing and manufactured by SSIC. Ceramic Sliding Bearing has a wide range of dimensions and is customized to fit your needs. It offers low friction and high performance. Moreover, it has certifications such as FDA, REACH, ROHS, ISO9001, ISO14001, ISO45001. The minimum order quantity is 20-50pcs and the price is negotiable. The packaging is foam+carton and the delivery time is 30-45 working days. The payment terms are T/T and the supply ability is 2000pcs per month.

Ceramic Sliding Bearing

Brand Name: SSIC

Model Number: SSIC Customized Products

Place of Origin: China

Certification: FDA, REACH, ROHS, ISO9001, ISO14001, ISO45001

Minimum Order Quantity: 20-50pcs

Price: Negotiable

Packaging Details: Foam+carton

Delivery Time: 30-45 works day

Payment Terms: T/T

Supply Ability: 2000pcs per month

Lifespan: Long

Noise: Low

Pressure: High

Load Capacity: High

Application: Machinery

Why choose us

Our factory and processing machine:

We have three factories in China, can meet the needs for different custmers, and also we have advanced pressing, sintering and processing machines.

Our company logo is ZXSQ and CSQ, and possesses eleven invention patents for utility models. The company now has a high-quality professional team consisting of dozens of members, to provide you with high-quality and perfect service, according to customer requirements to order a variety of bearing products.

Since the year of 1982 we have accumulated abundant experience in the production over the past more than 40 years, devoting ourselves whole -heartedly to the research and development of ceramic bearing material, our processing technique and improvement of our equipments.

Having undergone several evolution and transformation, our company has now become the leading enterprise in China domestic market in the fields of ceramic bearing and ceramic material products.

According to the structure difference, it can be divided into: external gear pump and internal gear pump. Our company has ample production experience of both kind of the gear pump sliding bearing in material of silicon carbide. We did supply these SSiC sliding bearing for Germany Witte for many years.

FQA

Q:Who are we?

A:We are a factory in Beijing, China. We have been producing and selling ceramic bearings for more than 40 years. We have established friendly cooperative relations with many domestic and foreign companies.

Q:How can we guarantee quality?

A:We always produce samples before mass production, and produce in strict accordance with customer requirements and production regulations. After the completion of production, we will use inspection equipment to carry out precise inspection of products, and our packaging adopts the double insurance of foam and carton, to strictly ensure the quality of products.

Q:What can you buy from us?

A:Ceramic deep groove ball bearings, ceramic angular contact ball bearings, hybrid ceramic ball bearings, ceramic linear bearings, etc and all kinds of ceramic balls.

Q:Why should you buy from us not from other suppliers?

A:We are an industry and trade integrated company, we have three factories, with today's production and inspection equipment, can provide better delivery dates and product quality.

Q:What service can we provide?

A:We will provide high quality products and customized services, which can be fully customized according to user needs. We can provide samples for customer's confirmation.

Welcome your enquiry

We supply bearings, high quality products, if you need to buy or consult the price of bearings, please contact us. We are a set of bearing research and development, production, sales, service in one of the professional bearing company, providing bearing products and related technical services. We choose high quality raw materials, carefully do each set of bearings.

We adhere to customer demand as the guidance, and strive to provide customers with quality products and after-sales service, create value for customers, do customers partner. Welcome to discuss the cooperation!