Zibo Huao New Materials Co., Ltd. |

|

Verified Suppliers

|

|

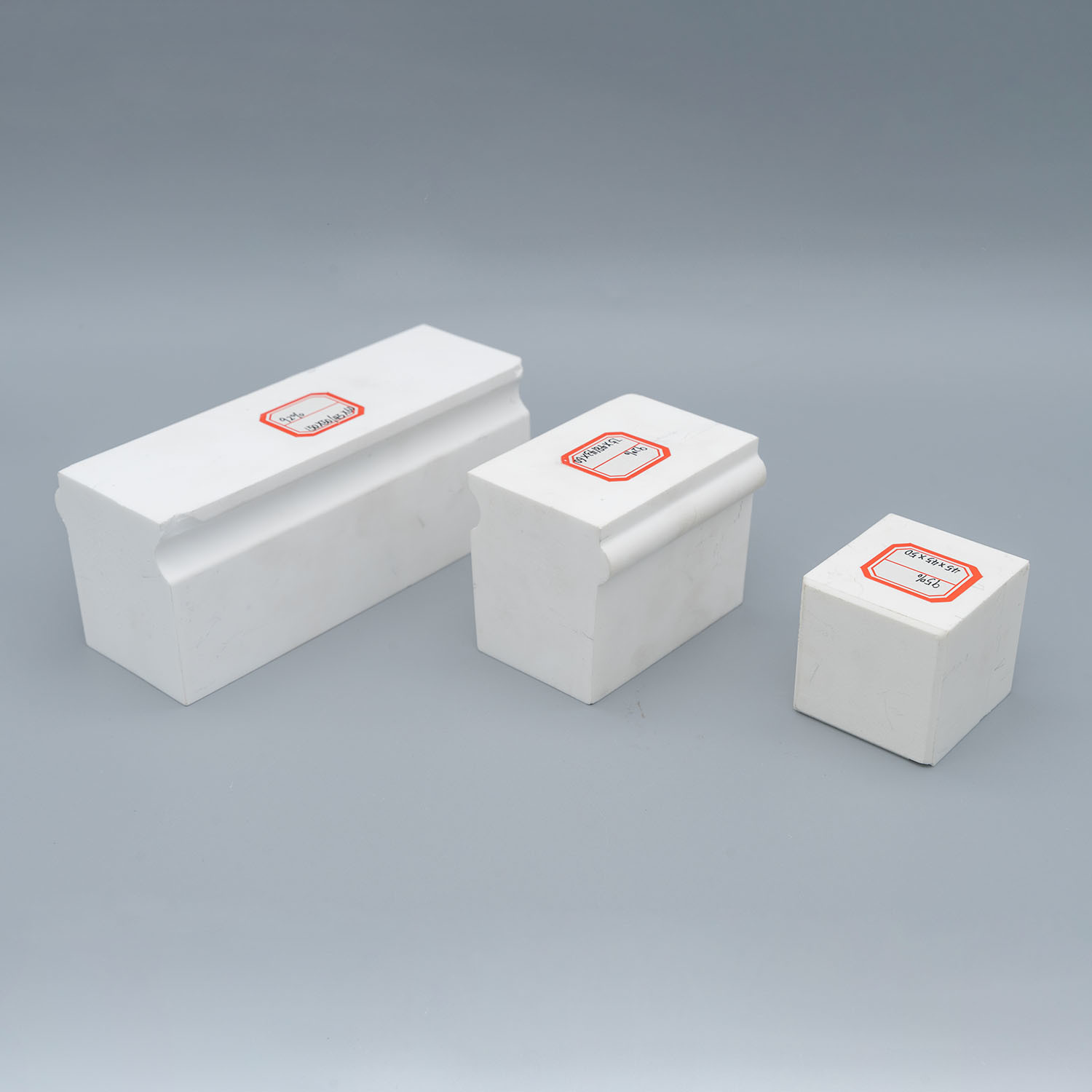

The Alumina Ceramic Brick is a type of high-performance ceramic material that is widely used as a wear-resistant lining in ball mills and pipelines. With its excellent properties of high hardness, wear resistance, and corrosion resistance, it is the preferred choice for industries such as mining, cement, and chemical processing.

| Color: | White |

|---|---|

| Alumina Content: | 92%, 95% |

| Bulk Density: | ≥3.60g/cm 3 |

| Size: | Customizable |

| Application: | Ball Mill and Pipeline as Wear-resistant Lining |

The Alumina Ceramic Brick is made from high-purity alumina oxide, with a content of 92% or 95%. This ensures its superior strength and durability, making it suitable for use in high-wear environments such as ball mills and pipelines. Its white color also adds an aesthetic appeal, making it a popular choice for industries that prioritize both functionality and appearance.

The Alumina Ceramic Brick is available in customizable sizes, allowing for easy installation and replacement. Its high bulk density of ≥3.60g/cm 3 also ensures a tight and secure fit, providing maximum protection against wear and tear. Its exceptional wear resistance and corrosion resistance make it a cost-effective solution for extending the lifespan of equipment and reducing maintenance costs.

In ball mills, the Alumina Ceramic Brick is used as lining to protect the inner surface from the constant impact and abrasion of grinding media and materials. This significantly extends the lifespan of the mill and reduces downtime for maintenance. In pipelines, the Alumina Ceramic Brick is used as a wear-resistant lining to prevent erosion and corrosion caused by abrasive or corrosive materials, ensuring the smooth flow of materials and minimizing the risk of leaks.

Overall, the Alumina Ceramic Brick is a high-quality, versatile, and reliable choice for industries that require wear-resistant and corrosion-resistant solutions. Its exceptional properties make it an essential component in maintaining the efficiency and longevity of equipment, making it a valuable investment for any industrial application.

| Product Name | High Alumina Bricks |

|---|---|

| Alumina Lining Brick | Alumina Oxide Ceramic Brick |

| Bulk Density | ≥3.60g/cm3 |

| Application | Ball Mill And Pipeline As Wear-resistant Lining |

| Color | White |

| Alumina Content | 92%, 95% |

| Size | Customizable |

| Hardness | 9 Mohs |

Alumina Oxide Ceramic Brick is a type of high-performance ceramic brick that is widely used in various industrial applications. It is made from high-purity alumina oxide, which gives it excellent properties such as high hardness, chemical resistance, and thermal stability. This makes it a suitable choice for extreme industrial environments where other materials may fail.

Alumina Oxide Ceramic Brick is usually packaged in cartons or wooden cases to ensure safe transportation and storage. This packaging method protects the bricks from any damage during handling and shipping, ensuring that they reach their destination in perfect condition.

To make it easier for our customers, we offer flexible payment terms for Alumina Oxide Ceramic Brick. You can choose to pay 100% in advance or opt for a 30% TT payment in advance, with the balance payment to be made before delivery. This allows our customers to plan their budget accordingly and ensures a smooth transaction process.

At Alumina Oxide Ceramic Brick, we understand that different industrial applications may have different requirements. That's why we offer customizable sizes for our ceramic bricks to meet specific customer needs. This allows our customers to use the bricks in a variety of applications, making them a versatile and cost-effective solution.

One of the key properties of Alumina Oxide Ceramic Brick is its high hardness, which is rated at 9 Mohs on the hardness scale. This makes it one of the hardest materials available, making it ideal for industrial applications that require resistance to wear, abrasion, and impact.

Our Alumina Oxide Ceramic Brick is available in two different alumina content options – 92% and 95%. This allows our customers to choose the best composition for their specific application. The higher the alumina content, the better the properties of the brick, making it suitable for more demanding industrial environments.

Alumina Oxide Ceramic Brick is known for its beautiful white color, which not only gives it an aesthetic appeal but also makes it easy to identify and distinguish from other materials. This white color is a result of the high purity of alumina oxide used in the production of the brick.

The bulk density of Alumina Oxide Ceramic Brick is an important factor to consider in industrial applications. Our bricks have a bulk density of at least 3.60g/cm3, which makes them highly dense and resistant to cracks and fractures. This ensures their durability and longevity in harsh industrial environments.

|  |

Our Alumina Ceramic Brick is a high-quality product that is designed to provide superior performance in industrial applications. We understand that every customer has unique needs and requirements, which is why we offer customization services for our Alumina Ceramic Brick.

Our Alumina Ceramic Brick is carefully packaged to ensure safe delivery. It can be packed in cartons or wooden cases depending on your preference.

We offer flexible payment terms to meet the needs of our customers. You can choose to pay 100% in advance or 30% TT in advance with the balance payment to be made before delivery.

Our Alumina Ceramic Brick has a bulk density of ≥3.60g/cm3, which makes it highly resistant to wear and tear.

Our Alumina Ceramic Brick has a hardness rating of 9 Mohs, making it one of the hardest and most durable materials available.

We offer customizable sizes for our Alumina Ceramic Brick to meet the specific requirements of your project.

Our Alumina Ceramic Brick is perfect for use as a wear-resistant lining in ball mills and pipelines, providing excellent protection against abrasion and corrosion.

Our Alumina Ceramic Brick is available in a classic white color, providing a clean and professional look for your industrial application.

Don't settle for standard products that may not meet your unique needs. Choose our Alumina Ceramic Brick and take advantage of our customization services to get a product that is tailor-made for your specific requirements. Our Alumina Oxide Ceramic brick, Alumina Oxide Ceramic brick, High Alumina Bricks, and Alumina Ceramic Lining Brick are all available for customization to ensure the best results for your project.