Zibo Huao New Materials Co., Ltd. |

|

Verified Suppliers

|

|

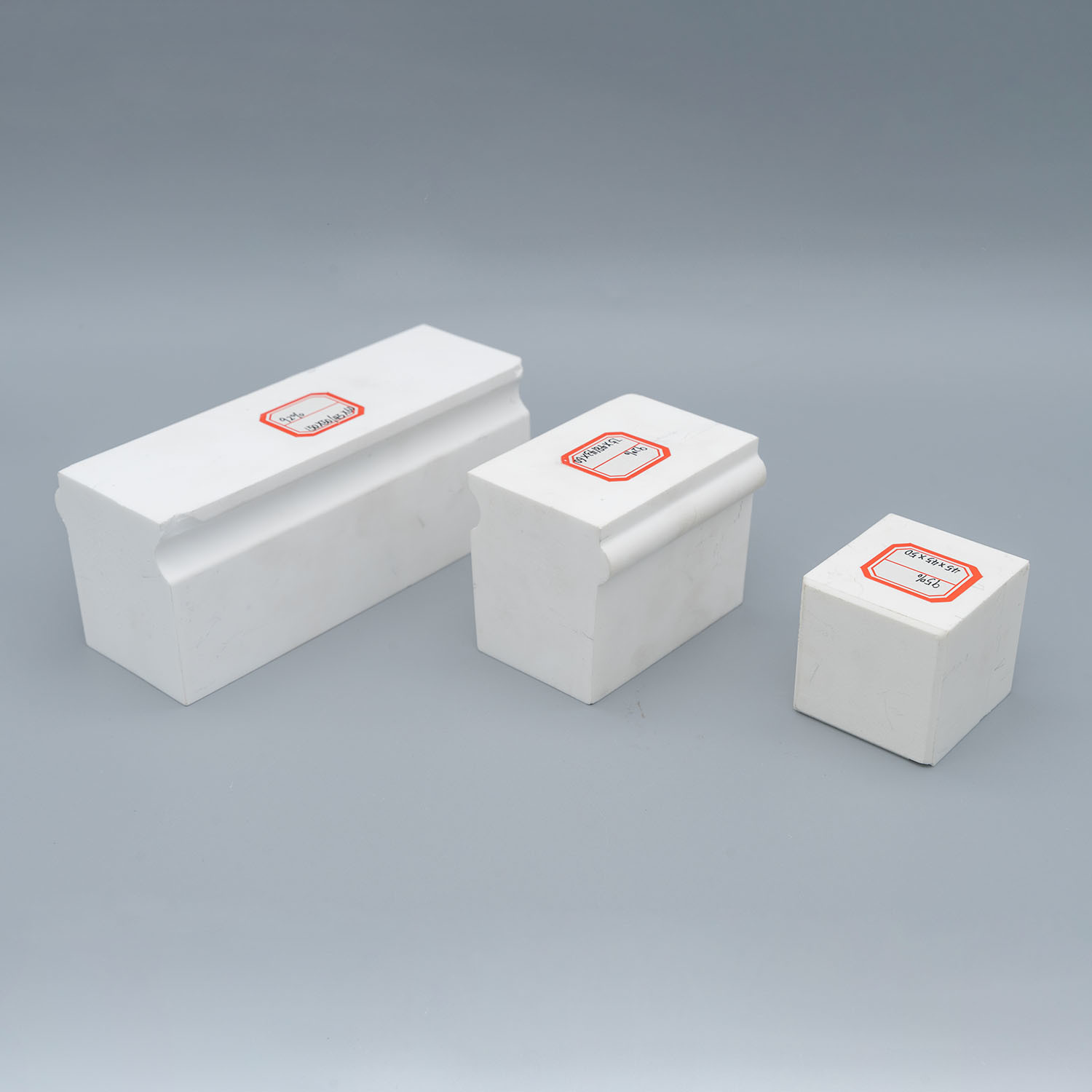

White Alumina Oxide Ceramic brick with High Density and Bulk Density ≥3.60g/cm3

Welcome to our product overview for the Alumina Ceramic Brick. This high-quality brick is made from alumina oxide ceramic and is known for its exceptional strength and durability. It is commonly used as a wear-resistant lining in various industrial applications such as ball mills and pipelines.

In conclusion, our Alumina Ceramic Brick is a highly versatile and durable product that can provide exceptional protection against wear and tear in high-impact areas. With its excellent bulk density, alumina content, hardness, and customizable thickness, it is the perfect choice for various industrial applications. Contact us today to learn more about our Alumina Ceramic Brick and how it can benefit your business.

| Item | AK-92 | AK-95 |

| Al2O3 | ≥92 | ≥95 |

| Bulk Density(g/cm3) | ≥3.6 | ≥3.65 |

| Hardness(Mohs) | 9 | 9 |

| Wear Loss(%) | ≤0.01 | ≤0.01 |

| Color | White | White |

Alumina Ceramic Brick, also known as Alumina Oxide Ceramic Brick or Alumina Lining Brick, is a type of high-quality ceramic material that is widely used in various industries due to its exceptional properties.

The primary application of Alumina Ceramic Brick is as a wear-resistant lining in Ball Mill and Pipeline systems. It is used to protect these critical components from the constant wear and tear caused by the materials passing through them.

With a hardness of 9 Mohs, Alumina Ceramic Brick is one of the hardest ceramics available in the market. This exceptional hardness ensures that it can withstand the high impact and abrasion of materials in Ball Mill and Pipeline systems, making it the perfect choice for wear-resistant lining.

Alumina Ceramic Brick has excellent chemical resistance, making it highly resistant to corrosion and chemical reactions. This property is crucial in industries where materials with high chemical content are being processed, as it ensures the longevity and reliability of the equipment.

Another significant advantage of Alumina Ceramic Brick is its excellent electrical insulation properties. This makes it the preferred choice for lining in applications where electrical conductivity needs to be minimized, such as in Ball Mill and Pipeline systems.

Alumina Ceramic Brick is available in various grades, with alumina content ranging from 90% to 99%. This wide range of options allows customers to choose the most suitable grade for their specific application, ensuring optimal performance and cost-effectiveness.

Overall, Alumina Ceramic Brick is a versatile and highly reliable material that offers excellent wear and chemical resistance, electrical insulation, and a range of alumina content options. Its usage in Ball Mill and Pipeline systems as a wear-resistant lining has proven to be highly effective, making it an essential component in various industries.

|  |

This service is designed for those who are in need of top-quality alumina ceramic bricks for various industrial applications. Our customized service will ensure that you receive the best product that meets your specific requirements and delivers outstanding performance.

Packaging Details: Every alumina ceramic brick will be carefully packaged in a carton or wooden case to ensure safe transportation and delivery to your doorstep.

Payment Terms: We offer flexible payment options to our customers. You can choose to pay 100% in advance or opt for 30% TT in advance with the balance payment before delivery.

Color: Our alumina ceramic bricks are available in classic white color, adding a clean and modern look to your industrial equipment and pipelines.

Application: These bricks are specially designed to be used as wear-resistant lining in ball mills and pipelines, providing excellent protection against abrasion and corrosion.

Chemical Resistance: Our alumina ceramic bricks offer exceptional resistance to various chemicals, making them suitable for use in harsh and corrosive environments.

Electrical Insulation: These bricks have excellent electrical insulation properties, ensuring safety and stability in high voltage applications.

Bulk Density: With a bulk density of ≥3.60g/cm3, our alumina ceramic bricks are highly durable and can withstand heavy loads and extreme temperatures.

If you are looking for high-quality, customized alumina ceramic bricks, look no further. Contact us now to place your order and experience the superior performance of our Alumina Ceramic Brick.

The Alumina Ceramic Brick is carefully packaged to ensure safe delivery to our customers. Each brick is individually wrapped in protective material and then placed in a sturdy cardboard box. The box is then sealed and labeled with the product name, quantity, and any necessary handling instructions.

We offer several shipping options for our customers, including standard ground shipping, expedited shipping, and international shipping. Our team works closely with trusted shipping partners to ensure timely and secure delivery of our products.

For larger orders, the Alumina Ceramic Brick may be shipped on pallets for added protection and easier handling. Each pallet is securely wrapped and labeled for identification.

Our packaging and shipping process is designed to protect the Alumina Ceramic Brick from any damage during transit, so you can be confident that your order will arrive in perfect condition.