Zibo Huao New Materials Co., Ltd. |

|

Verified Suppliers

|

|

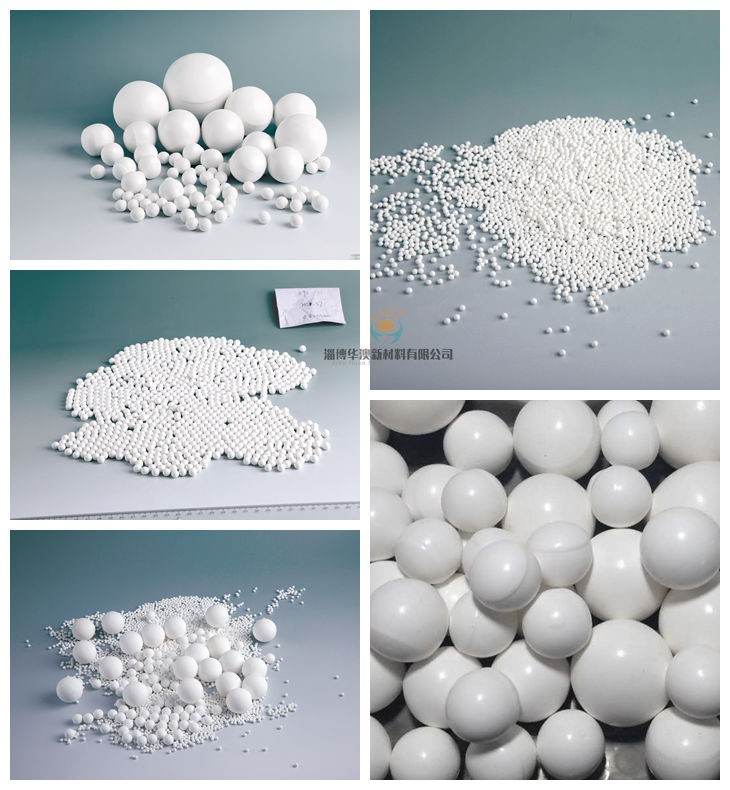

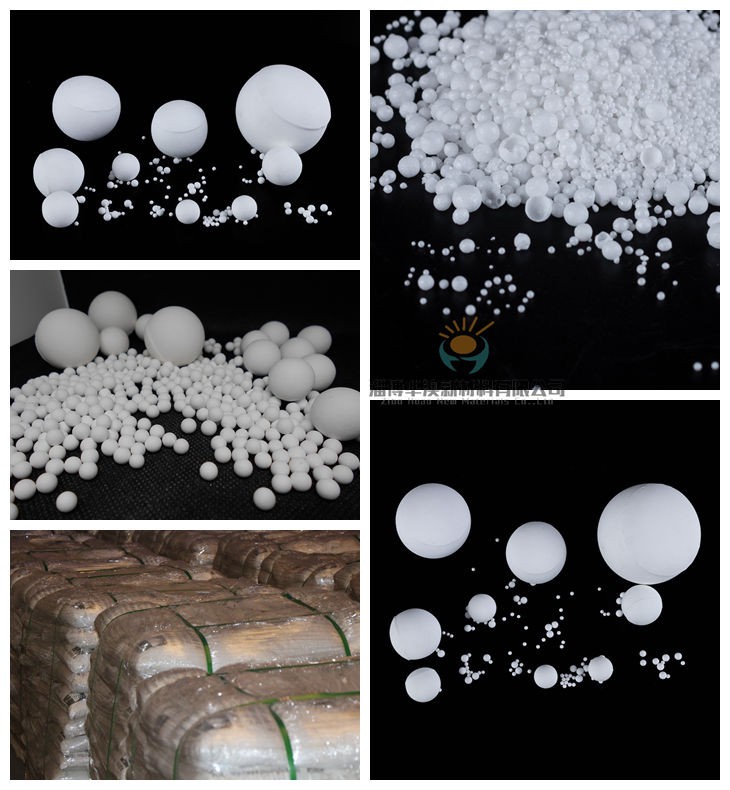

zirconia ceramic ball

Introduction

The wear-resistant medium of zirconium silicate beads is made of high-purity ultra-fine zirconium silicate powder, which has a uniform microcrystalline structure and no hollow inside. Compared with the electrofusion method and other zirconium silicate beads, the strength of zirconium silicate beads is higher and the cost performance is better. The microstructure of the beads is composed of dense zirconium silicate particles, which rejects the gap and cavity, avoids the separation of crystalline phase and glass phase, and has greater density and hardness than similar beads. Medium density and hardness suitable for medium and low viscosity slurry dispersion and grinding, can match most of the sand mill, for the universal grinding medium

Properties

Wear-resistant, not broken beads, very suitable for paint, coating, paper mill.

Dense crystalline phase structure high strength, wear;

Special ingredient high density high grinding efficiency;

High sphericity good fluidity large flow of material;

Solid bead not easy to break; Convenient color change;

Smooth spherical surface easy to clean; Small wear to the equipment;

Uniform particle size internal friction of beads; The particle size distribution of the milled product was uniform.

Size

∅0.2-0.4mm | ∅0.4-0.6mm | ∅0.6-0.8mm | ∅0.8-1.0mm | ∅1.0-1.2mm |

∅1.2-1.4mm | ∅1.4-1.6mm | ∅1.5-2.0mm | ∅2.0-2.5mm | ∅2.5-3.0mm |

∅3.0-3.5mm | ∅4mm | ∅5mm | ∅8mm | ∅10mm |

Technical data

ZTA280 | ZTA320 | ZTA370 | ZTA380 | ZTA450 | ZTA470 | |

AL2O3(%) | ≥57 | ≥70 | ≥87 | ≥66 | ≥5 | ≥3 |

ZrO2(%) | ≥5 | ≥5 | ≥5 | ≥18 | ≥62 | ≥70 |

SiO2(%) | ≤30 | ≤20 | ≤5 | ≤12 | ≤30 | ≤24 |

Bulk density(g/cm³) | ≥2.80 | ≥3.15 | ≥3.70 | ≥3.78 | ≥4.48 | ≥4.60 |

HV Hardness(Gpa) | ≥7 | ≥8 | ≥12.5 | ≥11 | ≥10 | ≥10 |

Crushing Strength(N) | ≥25 (∅1.5-2) | ≥800 (∅13.5) | ≥1000 (∅3) | ≥12000 (∅8) | ≥1200 (∅3) | ≥1300 (∅3) |

Water absorption | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

Wear loss rate(g/kg.h) | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

Sphericity | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |