Loudi Antaeus Electronic Ceramic Co.,Ltd. |

|

Verified Suppliers

|

|

LATF16949 Anti Corrosion Precision Ceramic Housing To Metal Brazing Contactor For Electric Car Relay

1. Description:

In multi-station assembly systems, common for mass-customization manufacturing strategies, the product being assembled is held in a fixture attached to a pallet, and the pallet is conveyed between workstations. In high-precision assembly systems, variation in the position of the pallet is one of the largest sources of variation within the error budget, reducing quality and yields. Conventional approaches to locating pallets use pins and bushings, and a method for predicting their repeatability is presented. This paper also presents an exact constraint approach using a split-groove kinematic coupling, which reduces variation in pallet location by an order of magnitude.

2. Features of alumina ceramic parts:

* Excellent insulation

* High Mechanical Strength

* Outstanding Electrical and Electronic Properties

* Wear Resistance

* Extreme Temperature Stability

* Resistant to Corrosion and Chemical Attack

* Gas and Liquid Tight

3. Material Features / Properties:

| Color | White or Ivory | White or Ivory | White or Ivory | |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics | ||||||||

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | Pass | - | |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | Pass | Pass | Pass | - | - | - | |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | ≤8 | - | |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - | |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | - | 4 | ||

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - | |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ | ||||||||

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - | |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - | |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - | ||

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - | ||

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - | |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

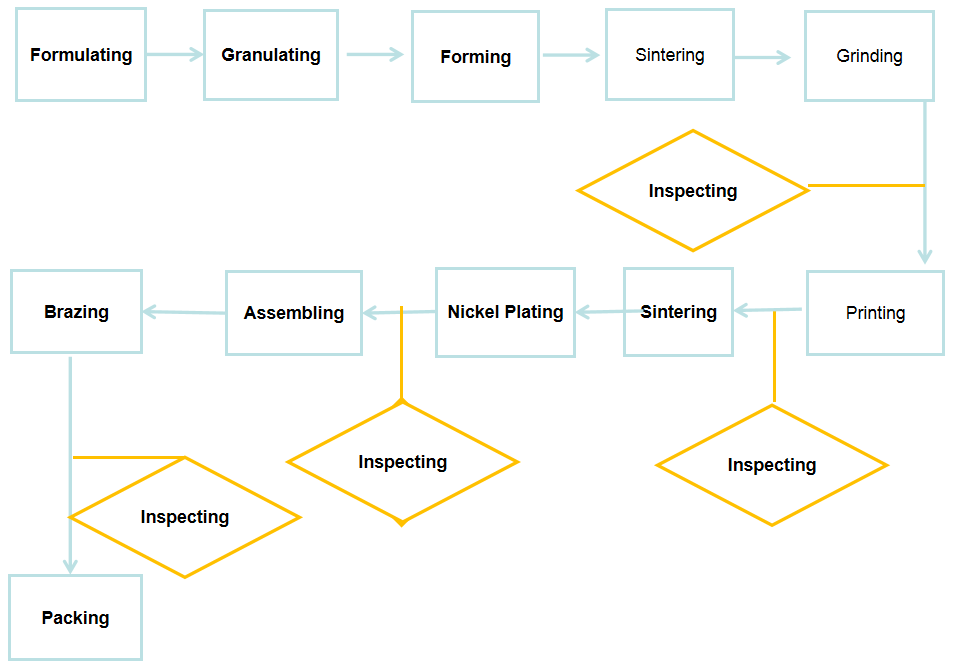

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Inspecting --- Packing

6. Application Fields:

New energy vehicles, charging piles, solar power generation, energy storage and power storage system, electric vehicle power system and so on.

7. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

8. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter

9. Order Flow Steps as belows: Inquiry ---Quotation --- Place an order --- Production --- Delivery

10. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ; Good Service

11. Shipping and Package:

12. Our aimed market:

13. Guiding questions for material selection:

In order to select the appropriate material for your application, there are several questions that you should consider.

1) Are the mechanical properties important?

2) Will the part be exposed to wear/friction/impacts?

3) How many pieces are you looking to have made in your first batch?

4) What type of atmosphere will the part be operating in; inert or oxidizing?

5) What is the maximum operating temperature of the component?

6) Will the component experience any thermal shock?

7) Is electrical insulation important?

8) Is thermal conductivity important?

9) How important are tolerances and surface finish?

Loudi Antaeus Electronic Ceramic Co.,Ltd is located in China, and it is a manufacturer and international supplier of advanced technical ceramic products since 2004. Our customer base, which includes many Fortune 500 companies.

The Company has developed a wide range of ceramic and assemblies that are used in various industries such as new energy vehicles. Antaeus Ceramics is equipped with state-of-the-art manufacturing facilities and technical expertise to develop and supply ceramic components as per customer design and specifications.

Our high performance ceramic products made from al2o3 Alumina, Zirconia,among others finds wide application in various industries that requires high temperature resistance, chemical resistance, wear resistance, electrical insulation or mechanical strength.

Application:

These Advanced technical ceramic components find application in a number of industries, some of them being sealing technology, pumps, wire-drawing, battery/ cell manufacturing, sand-blasting, chemical, electronics, textile, automotive, etc.

Customized are welcome according to your drawings or samples.

FAQs (Frequently Asked Questions)

Q1. Are you a factory or trading company?

A: We are a manufacturer of over 19 years of experience. Welcome to

visit our factory.Factory address is Loudi Economy and

Technological Development Zone,Hunan,China.

Q2: Do you send a sample to check?

A: Sure, sample in stock is free and freight collect.

Q3: When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If

urgent ,Please call us or chat online.

Q4:What is your Capacity?

A:300,000 pcs per day;

Q5: Are the ceramics good quality?

A:We have passed the complete quality-control system

ISO9001,IATF16949, ISO14001 and IRIS certification. We have more

than 200 advanced testing equipment and instruments,All the Alumina

ceramics are 100% fully inspected,including IQC, IPQC, FQC, and OQC

process.

Q6:What is the Lead time?

A: About 15-35 days,according to the quantities required;

Q7: Is it available to provide customized products?

A:We can do OEM and ODM.

Notes:please feel free to contact us for more details when you have any inquiry!

Loudi Antaeus Electronic Ceramic Co.,Ltd

Factory address:Loudi Economy and Technological Development Zone,Hunan,China.

Contact person:Alice Deng

Tel:+8615073852630 (wechat)

Mail: alice@andidz.com

Skype: alicedeng0629