Loudi Antaeus Electronic Ceramic Co.,Ltd. |

|

Verified Suppliers

|

|

Alumina ceramic components / relay ceramic assemblies / ceramic - metal brazed contactor

1. Description:

The authors introduce a pressing/damascening replication process on glass plates. As a prototype replication, the 20 μm line-wide circuit pattern was experimented. A male-patterned tungsten carbide mold hot-pressed against a glass plate to replicate the female pattern on the glass. Then the copper was deposited on the pressed glass, and was polished flat to produce the same copper damascened pattern. Next the three-layered circuit board was stacked and fixed by hot-pressing with only 2 μm error in the line width.

2. Feature Advantages:

1) High elasticity modulus

2) High compressive strength.

3) Anti corrosion

4) Abrasion resistance

5) Impact resistance

6) High precision

7) High stability

8) Good advanced ceramic materials

9) High welding sealing performance

10) High hardness and high density

11) Low thermal conductivity

12) Chemical inertness

13) Good wear resistance

14) High Fracture toughness

15) Good insulation performance

16) High temperature resistance

17) A variety of specifications is available

18) Satisfy various technical requests

19) Lower medium spoilage

20) Stiffness texture

21) Widely apply for automotive ceramic sensor , ceramic heater ,electric heating

3. Material Features / Properties:

| Color | White or Ivory | White or Ivory | White or Ivory | |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics | ||||||||

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | Pass | - | |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | Pass | Pass | Pass | - | - | - | |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | ≤8 | - | |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - | |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | - | 4 | ||

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - | |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ | ||||||||

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - | |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - | |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - | ||

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - | ||

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - | |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

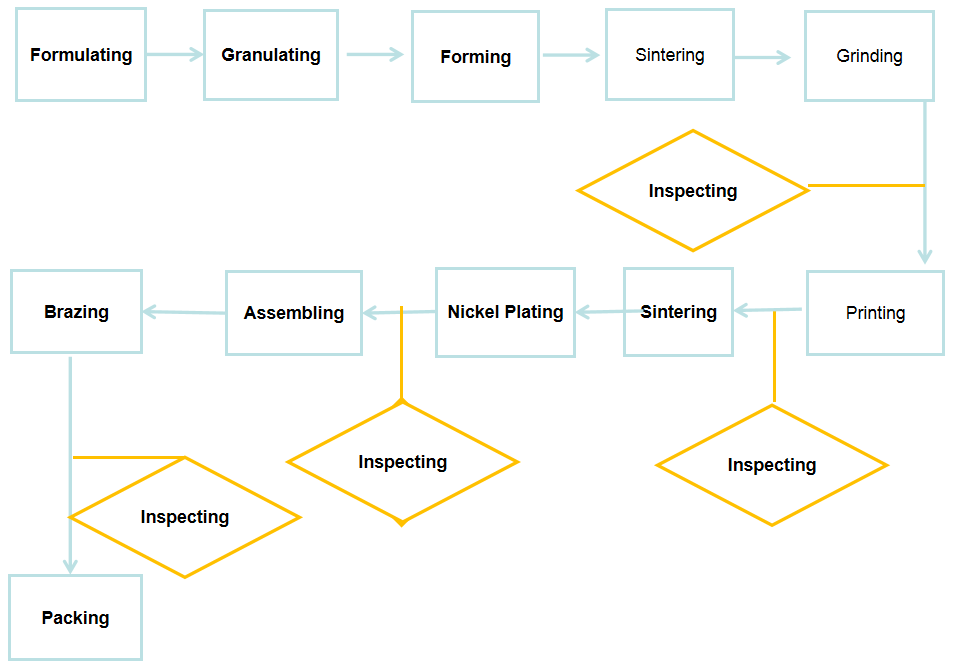

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Inspecting --- Packing

6. Application Fields:

New energy vehicles, charging piles, solar power generation, energy storage and power storage system, electric vehicle power system and so on.

7. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

8. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter

9. Order Flow Steps as belows: Inquiry ---Quotation --- Place an order --- Production --- Delivery

10. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ; Good Service

11. Shipping and Package:

12. Our aimed market:

13. Guiding questions for material selection:

In order to select the appropriate material for your application, there are several questions that you should consider.

1) Are the mechanical properties important?

2) Will the part be exposed to wear/friction/impacts?

3) How many pieces are you looking to have made in your first batch?

4) What type of atmosphere will the part be operating in; inert or oxidizing?

5) What is the maximum operating temperature of the component?

6) Will the component experience any thermal shock?

7) Is electrical insulation important?

8) Is thermal conductivity important?

9) How important are tolerances and surface finish?

Notes:Above information only for reference and please contact with us for more details freely when you have any inquiry!