Loudi Antaeus Electronic Ceramic Co.,Ltd. |

|

Verified Suppliers

|

|

Alumina Advanced Engineering Ceramics / Special Technical Ceramic Parts

1. Description:

Alumina advanced engineering ceramics / special technical ceramic parts widely apply for many different fields.Titanium Silicon Carbide has the high stiffness and high temperature properties expected of ceramics, but also the good thermal and electrical conductivity of metals. The layers that form in this ternary also somewhat inhibit crack propagation – meaning while this material does still experience brittle failure, it is significantly tougher than would be expected from a ceramic.The superconductors we mentioned earlier also have complex crystal structures where a variety of different bond types are present and these are carefully tuned to create electrons which can move through channels in the crystal unimpeded.

1) High hardness and high density

2) Low thermal conductivity

3) Chemical inertness

4) Good wear resistance

5) High Fracture toughness

6) Good insulation performance

7) High temperature resistance

8) A variety of specifications is available

9) Satisfy various technical requests

10) Lower medium spoilage

11) Stiffness texture

12) Chemical inertness

13) Good wear resistance

14) High Fracture toughness

15) Good insulation performance

3. Material Features / Properties:

| Color | White or Ivory | White or Ivory | White or Ivory | |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics | ||||||||

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | Pass | - | |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | Pass | Pass | Pass | - | - | - | |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | ≤8 | - | |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - | |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | - | 4 | ||

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - | |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ | ||||||||

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - | |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - | |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - | ||

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - | ||

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - | |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

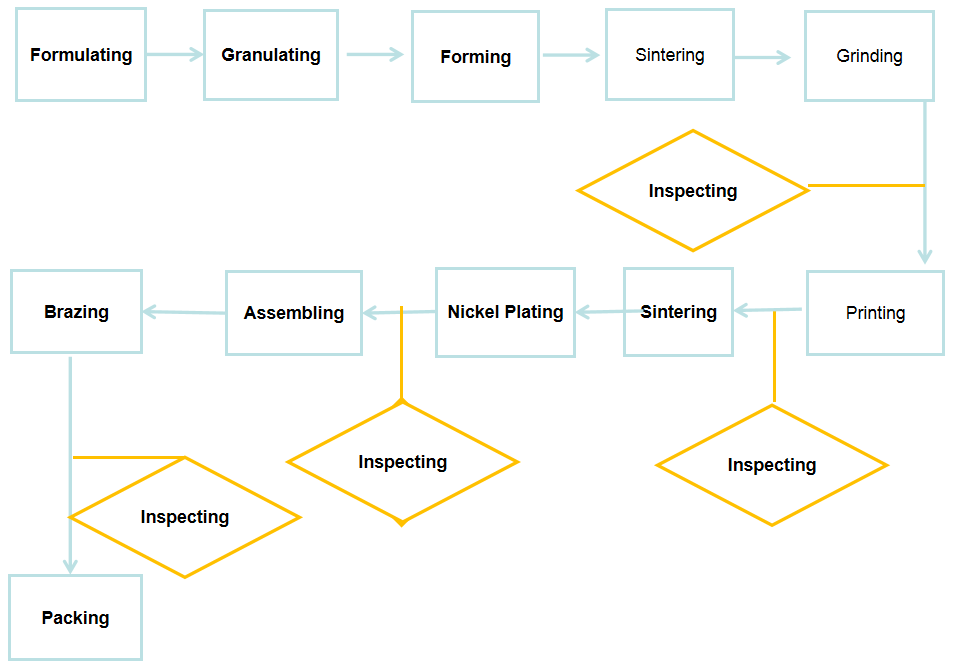

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Printing --- Nickel Plating --- Assembing --- Brazing --- Inspecting --- Packing

6. Application Fields:

Widely apply for new energy vehicles, charging piles, solar power generation, energy storage and power storage system, electric vehicle power system and so on.

7. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

8. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter

9.Order Flow Steps as belows: Inquiry ---Quotation --- Place an order --- Production --- Delivery

10. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ; Good Service

11.Shipping and Package:

12. Our aimed market :

Notes:Above information only for reference and please contact with us for more details freely when you have any inquiry!