Shanghai Xinyu Packaging Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Three Line Automatic Egg Washing And Breaking Line

Products Description

The machine is 304 stainless steel, corrosion resistance, good heat resistance, low temperature strength and mechanical properties. The use of the production line can be carried out on the water for cleaning the eggs, egg drying, automatic break egg machine.

1, User-friendly design, low operating costs, adaptability

2, Made of stainless steel, easier cleaning and maintenance

3, The use of imported brush, durable wear, the use of brush in the process can adjust the amount

4, Software and hardware are developed and produced by the company themselves, and can provide fast technical support

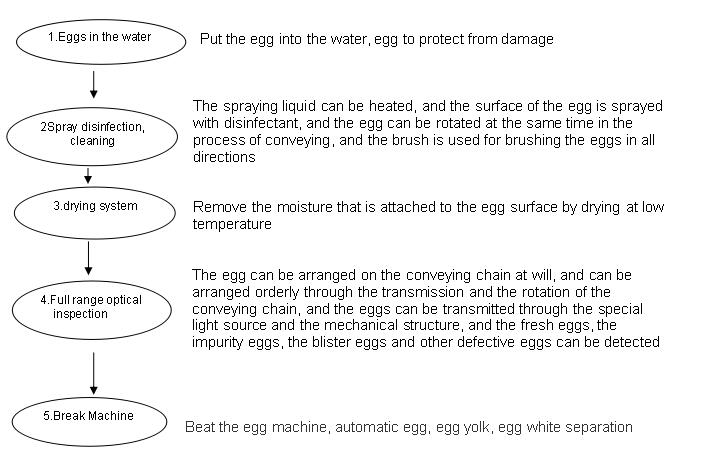

Process flow diagram and instructions

Characteristic structure

1,The utility model has the advantages of good anticorrosion and alkali resistance, beautiful appearance, reasonable structure and long service life

2,The plastic parts produced by mould can meet the requirements of corrosion protection on the basis of ensuring the mechanical properties, and greatly improve the service life of the equipment

3,Two piece type four nanometer molecular wear silk brush, brush ability super, durable wear

4,The utility model has the advantages of simple operation, low failure rate, convenient maintenance, high production efficiency, low crushing rate and clean cleaning

5,500kg/ hours of production efficiency, the entire process requires only 2-3 people to operate,Compared with the traditional process, 8-10 people can be reduced

6,Full line operation, reduce unnecessary logistics and damage, can reduce the breakage rate of 2 per thousand

7,Labor intensity is greatly reduced and labor cost is greatly reduced

8,It is suitable for fresh egg, fresh duck's egg, egg mud, ash eggs, eggs and other various types of cleaning salt processed eggs.

Picture flow description

Ⅰ,Eggs in the water

Ⅱ,Spray, disinfection, cleaning system

Spray, disinfection: can spray liquid heating, but also on the surface of the egg spray disinfectant

Cleaning brush: brush made of nylon DuPont wire material, soft hard moderate, to ensure the clean and maintain the egg egg and the egg is not broken. In the process of transmission and ensure the rotation, the brush uses high and low device on egg full brushing

Ⅲ,Drying system

Brush at the same time without adding tap water to scrub the eggs at low temperature.

By drying at low temperature, remove the water that is attached to the surface of the egg, and use the low temperature produced by the fan to dry to ensure the freshness and integrity of the egg, which will not cause the deterioration of the egg due to the high temperature.

Ⅳ,Single row full range optical inspection system

The whole set of transportation: eggs can be placed on the conveyor chain at will, and can be arranged in an orderly arrangement by the transmission and rotation of the conveyor chain

Photo penetration test: the use of a special light source and mechanical structure of the egg transmission, can check out fresh eggs, eggs, blisters, eggs and other substandard eggs

Ⅴ,Single row egg breaking machine

1,The machine adopts automatic feeding system, saving labor

2, Separate designs are used to automatically separate yolk and proteins

3, Can also choose the mixed egg separation.

4. Collect eggshells automatically and keep the environment clean at any time

5, The whole machine is made of stainless steel and easy to clean

Ⅵ,Electrical control system

Ⅶ,Parameter

Weight:1200kg

Dimension:7600*1300*1700(mm)

Voltage:380V

Power:7.5kw

Capacity:10000-15000pieces/h