Anping Jiongcan Hardware Mesh Products Co., Ltd |

|

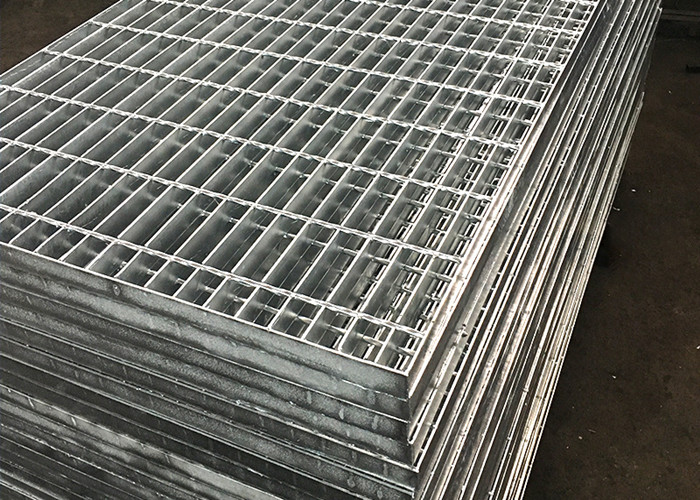

According to the construction requirements can choose to use flat steel and twisted square steel (twist steel) cross welding of ordinary steel grid plate or flat steel and flat steel cross welding of plug steel grid plate.Platform grid plate is generally made of Q235 low carbon steel, hot dip galvanized appearance, can play a role in preventing oxidation, the service life can reach more than ten years.

Learn more about the main components of metal bar grating | |

| Span: | Total span. |

| Width: | Panel width. |

| Bearing Bars: | Load carrying main element. |

| Bearing Bars Spacing: | Measure from center-to-center of the bearing bars in 1/16″ increments. Standard spacing for industrial flooring is 19/16″(1-3/16″) on center. Other popular spacings are 15/16″, 11/16″, 1/2″, and 7/16″ on center. |

| Bearing Bars Depth: | Ranges from 3/4″ to 7″ depending on anticipated loads. |

| Bearing Bars Thickness: | Ranges from 1/8″ to 1/2″ depending on anticipated loads. |

| Cross Bars: | Used to Secure the position of bearing bars. |

| Cross Bar Spacing: | Measured from center-to-center of cross bars in 1″ increments. Standard spacing is 4″ or 2″ on center. |

1, flat steel spacing of 30mm steel grid plate plate for the

industrial field of more widely used varieties.

In the series of commonly used steel grid plates, the surface

impact has a relatively strong resistance.

2, flat steel spacing of 40mm steel grid plate plate for the more

economic, more lightweight varieties.

In the context of relatively small span, is an ideal choice.

3, flat steel spacing of 60mm, bar spacing of 50mm steel grid plate

is designed for the application of mining and the development of

the variety, it solves the problem of mineral splashing on the

surface, often designated for mining processing plants, transfer

stations, crushing system of the surface.

Platform steel grid board is widely used in petrochemical, electric power, water, sewage treatment, port and wharf, construction and finishing, shipbuilding, self-walking parking lot, municipal engineering, sanitation engineering and other areas of platform and walkway, trench cover, manhole cover, ladder, fence and so on.

1. High strength, light weight;

2. Strong anti-corrosion ability, durable;

3. Beautiful appearance, bright surface;

4. No dirt, no rain and snow, no water, self-cleaning, easy to maintain;

5. Good ventilation, lighting, heat dissipation and skid resistance;

6. Easy to install and disassemble.

Key points of steel grid welding technology

At each intersection of the load flat steel and the bar, it shall be fixed by welding, riveting or pressure locking.2, steel grid welding preferred to choose pressure resistance welding, can also choose arc welding.3. The press lock of the steel grid plate can be used to press the transverse bar into the load flat steel and fix it.4, steel plate should be based on the needs of users, processed into a variety of sizes of the shape.

The steel grid plate is made of flat steel in accordance with a certain distance and bar (twisted square steel, square steel, round steel, flat steel, etc.) for interpenetration and placement, and welded into a kind of finished steel with square grid in the center. The steel grid plate is mainly used to make the ditch cover plate, the steel structure channel plate, the stepping plate of the steel ladder, etc.The bar is usually made of twisted square steel.The steel grid is usually made of carbon steel, and its surface is hot dip galvanized, which can prevent oxidation.Can also choose stainless steel manufacturing.The steel grid has the functions of ventilation, lighting, heat dissipation, anti-skid and explosion proof.

Using steel case board installation clip for installation of steel case board with does not destroy the characteristics of the coating, generally applicable to the often need to remove the steel plate used above, each steel plate to be used at least four installation clip, each corner a, for the steel plate with larger area should guarantee per square meter of steel case board installation amount shall not be less than 4.The steel grid plate mounting clamp is divided into three parts: upper clamp, lower clamp and fastening bolt.