SHANGHAI E&V IMPORT AND EXPORT CO.,LTD |

|

Verified Suppliers

|

|

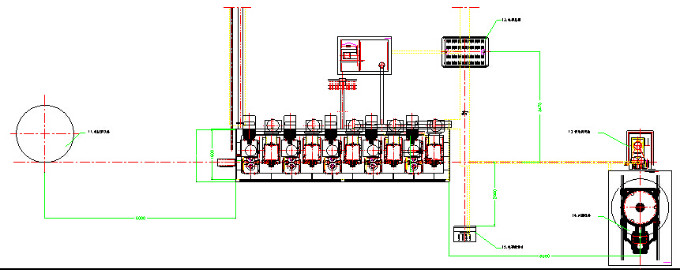

copper alloy rod rolling mill

I. major information

The unit is used for copper rod cold rolling. Through cold rolling,

the mechanical behavior can be raised and the defects from casting

can be also fetched up. The producing capacity is 2.5ton / hour.

Mechanical design uses advanced crafts and high-quality materials, such as roller; the appearance of the machine adopts German design,which has higher work efficiency than other similar products;Electrical parts assemble the imported parts from Japan, which have safe and reliable performance, high technological content; the whole production process is monitored by color touch screen with clear data displaying, easy operating and high automaticity. 2 high motive power frame copper rod rolling mill is beautiful, efficient and durable.

II. Advantage

1.seperate motor

2.high quality

3.good reponds

4.roll diffient material

5.roll diffient size

6.Perfect service,timely customer response

7.hIgh quality

III.Main Data

| No. | item | Parameter |

| 1 | Model: | Copper rod cold rolling mill, copper alloy cold rolling mill. Other metal rod cold rolling mill, other alloy cold rolling mill,copper / aluminum continuous casting and rolling etc. |

| 2 | Input dia | Ф55mm,Ф35mm,Ф25mm,Ф20mm,Ф17mm,Ф16mm,Ф14.4mm,Ф12.5mm,Ф8mm etc. |

| 3 | Output dia | Ф20mm,Ф18mm,Ф17mm,Ф8mm,Ф6mm,Ф5mm,Ф4mm,Ф3 mm etc. |

| 4 | Outlet rod out of roundness | No more than 0.2mm after rolling, or more accurate |

| 5 | Rolling pass | 2-16 or as each customer’s requirements |

| 6 | Rolling speed | Max 3M/s for continuous rolling, Max 5M/s for discontinuous rolling. |

| 7 | Pass schedule | ellipse-round hole type system or triangular -round type system |

| 8 | total extend compression ratio | 2-10, or as each customer’s requirements |

| 9 | each pass compression ratio | 1.15~1.4(hole type can change) |

| 10 | Total power | 100kw~500kw |

| 11 | Running mode | Each frame separate transmission speed controlled by frequency or AC servo |

| 12 | Operation mode | PLC control, touch screen display,can improve to DCS control or networking |

| 13 | type | 2 high horizontal- vertical or 3 high positive triangle-inverted triangle |

| 14 | nominal roller dia | Ф200mm(double-groove/multi-groove),Ф248mm(double-groove/multi-groove),Ф264mm,Ф300mm,Ф370mm,Ф400mm etc. |

| 15 | No. of frame | 2-16 or more |

| 16 | Main motor | 11kw-110kw AC frequency motor or AV servo motor for each |

| 17 | roller material | other imported material etc. |

| 18 | rolling mill size | a complete production line: length 18m *width 6 m*height 2.5m Main machine : length 7.6m*width 2.3m *height 2m |

| 19 | height of center | height from the ground 1230mm |

IV.Equipment Configuration List

| No. | Name | Model and main parameter | Unit | quantity |

| 1 | Main machine | set | 1 | |

| include | Frequency motor reducer | set | 8 | |

| 2 | Coiling machine | set | 1 | |

| 3 | Pay-off frame | set | 1 | |

| 4 | emulsion system | Part fittings are provided | set | 1 |

| 5 | oil lubrication system | set | 1 | |

| 6 | Electronic control system | set | 1 | |

| 6.1 | PLC system | set | 1 | |

| 6.2 | Main converter | set | 8 | |

| 6.3 | Electrical panel | pc | 1 | |

| 7 | Other parts | set | 1 |

V.After-sale service

Before sale: design the suitable machine based on the specific demands Medium sale:

1.based on customer’s demand to offer moderate quotation project

2.accept customers to visit our factory

3.help customer work out the schedule in china

After-sale:

1.on-site training personnel 2. appoint special after-sale service staff, arrived at the scene guide clients installation and commission

VI.FAQ

1. What’s your MOQ?

At present we haven’t strict policy for this, so welcome orders with any quantity.

2. how to contact with sales ?

You can send inquiry of our products,it will be replied within 6 hours;

you can contact directly with our sales through WhatsApp as you like.

3. What raw material do you use?

Magnesium copper, brass,Neickel-copperl, Silver-copper alloys, Tungten and niobium, etc.

55mm, 35mm, 25mm, 20mm, 17mm, 16mm, 14.4mm, 12.5mm, 8mm

20mm,18mm, 17mm, 8mm, 6mm, 5mm, 4mm, 3mm