SHANGHAI E&V IMPORT AND EXPORT CO.,LTD |

|

Verified Suppliers

|

|

saling copper alloy rods cold rolling mill/copper rod and wire cold

rolling mill

I. major information

Mechanical design uses advanced crafts and high-quality materials,

such as roller; the appearance of the machine adopts German

design,which has higher work efficiency than other similar

products;

II. Advantage of 2 high cold rolling mill

Rollers of each rolling stand are driven by separate inverter

motor. When the shape of the pass and rotating speed of each pass

stand roller are changed at the same time, each stand can operate

asynchronously. Processing rollers can change the shape of the

pass, and the gear ratio of each stand roller can be set on the

touch screen. So on the premise of meeting the stand strength,

2-roller copper rod cold rolling mill can roll different dimensions

of copper rod and also roll other materials.

III.Main Data

No. Item Data

1 Model 20mm-8mm cold rolling mil for oxygen free copper rod

2 Inlet dia 20.0mm

3 Outlet dia 8.0mm

4 Outlet rod out of roundness No more than 0.2mm

6 Rolling pass 10

7 Rolling speed Max 1.6 M/S

8 Pass schedule ellipse-round hole type system

9 total extend compression ratio 6.25

10 each pass compression ratio 1.15-1.3

11 Total installing power 200kw

IV.Main component

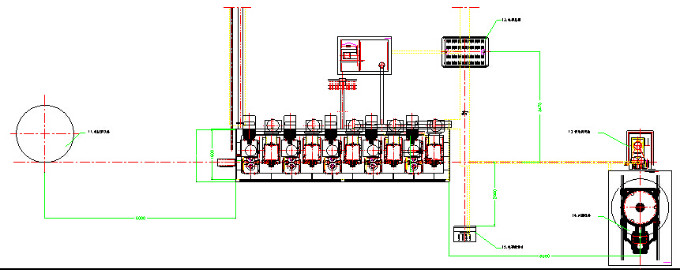

1. Rolling mill base 2. 2-roller motive power frame(including reducer, Inverter motor) 3. Pay-off frame 4. coiling take-up system 5. Lubrication system 6. Emulsion system 7. Electronic control system 8.straightening device

V.Spare parts for 20mm-8mm forming units

| No. | Name |

| 1 | rollers |

| 2 | Roll shaft |

| 3 | guide |

| 4 | Expansion sleeve |

VI.Technical process

1.check the device

2.touch screen to enter into the normal working screen,

3.open the oil pump

4.open the emulsion pump

5.rolling copper rod

6.increase speed

55mm, 35mm, 25mm, 20mm, 17mm, 16mm, 14.4mm, 12.5mm, 8mm

20mm,18mm, 17mm, 8mm, 6mm, 5mm, 4mm, 3mm

Dear friends,

welcome to contact with us!